Abstract

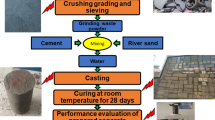

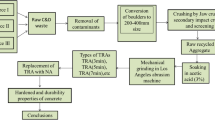

Secondary aluminum swarf is a residue from the turning or drilling process that originates after the metal melting phase. It is a major problem in Peru because there is no management of this type of solid waste and it contaminates the soil. Therefore, as a way to reduce the accumulation rates of aluminum scrap, this study proposes the incorporation of secondary aluminum chips in the production of concrete, where its physical and mechanical properties were studied. This experimental study prepares two types of concrete, based on crushed sand and coarse aggregate with the incorporation of aluminum chips in percentages of (0.5, 1.5, 3.5 and 5%) in weight of cement, with dimensions of 2 mm in diameter and 60 mm in length. An experimental program was carried out to determine the slump, air content, unit weight, temperature and mechanical strength (compressive, tensile and flexural) at 28 days of the experimental concrete. According to the results, the slump decreases with increasing doses of chips therefore the workability was considerably reduced but the other properties tended to increase their values which are considered acceptable for physical properties. On the other hand, in compressive strength with the 0.5% percentage of chips, it increased its strength from 6.59 and 4.47% with respect to the control samples, while with other higher percentages evaluated there were low strengths even below the control samples; in splitting tensile strength, the samples with 3.5% of chips increased between 12.79 and 8.64% and in flexural strength increased between 25.72 and 20.37%, respectively. It was found that the inclusion of chips does not generate an impact greater than 10% in its compressive strength, compared to when subjected to flexural and tensile stresses at 28 days of rupture. The result of the present study contributes that it is technically feasible for the production of non-structural concrete.

Source: Authors

Source: Authors

Source: Authors

Source: Authors

Source: Authors

Source: Authors

Similar content being viewed by others

Change history

15 March 2024

A Correction to this paper has been published: https://doi.org/10.1007/s41062-024-01434-4

References

Ali FC, Govar H, Mohammed DA, Haluk I (2020) Aluminum waste in road pavement subgrade. Eng Research 40(1):8–16

Panditharadhya BJ, Sampath V, Mulangi RH, Shankar AR (2018) Mechanical properties of pavement quality concrete with secondary aluminium dross as partial replacement for ordinary portland cement. In: IOP conference series: materials science and engineering, 431: 032011, 2018.

Arimanwa J, Onwuka D, Arimanwa M, Onwuka U (2012) Prediction of the compressive strength of aluminum waste-cement concrete using scheffe’s theory. J Mater Civ Eng 24(2):177–183

Kumar P, Christy J, Arunachalam R, Mourad A-H, Muraliraja R, Al-Maharbi M, Murali V, Manik M (2019) Production of aluminum alloy-based metal matrix composites using scrap aluminum alloy and waste materials: influence on microstructure and mechanical properties. J Alloy Compd 784:1047–1061

Mahinroosta M, Allahverdi A (2018) Hazardous aluminum dross characterization and recycling strategies: a critical review. J Environ Manage 223:452–468

Meshram A, Kumar K (2018) Recovery of valuable products from hazardous aluminum dross: a review. Resour Conserv Recycl 130:95–108

Oresanya T, Ben-Enukora C, Omojola O, Oyero O, Amodu L (2017) Health communication and awareness of aluminium-waste disposal effects among Ogun state housing corporation residents. New Trends Issues Proc Humanities Social Sci 4(10):128–135

Tulope R, Busari A (2019) Influence of hhite aluminum dross on the corrosion resistance of reinforcement carbon steel in simulated concrete pore solution. J Bio- Tribo-Corrosion 5(1):838–845

Busari A, Joseph F, Ajayi S, Alayande T, Nwachukwu J, Agbama D (2019) Index properties of aluminum dross modified pavement geomaterial-material. J Phys: Conf Ser 1378:1–8

Zeng L, Liu H, Wang H, Tang G, Liang Q, Liu Y (2013) Resource recycling of waste slag og aluminum factory. Adv Mater Res 779–780:1254–1259

Patil L, Nayak CB, Jagadale UT (2022) Effect of copper slag and fly ash and Nano Material to strengthen the properties of concrete. J Emergin Technol Innovative Res (JETIR) 9(6):831–838

Javali S, Chandrashekar AR, Naganna SR, Manu DS, Hiremath P, Preethi HG, Kumar NV (2017) Eco-concrete for sustainability: utilizing aluminium dross and iron slag as partial replacement materials. Clean Technol Environ Policy 19:2291–2304

Sabapathy YK, Sabarish S, Nithish CNA, Ramasamy SM, Krishna Gokul (2021) Experimental study on strength properties of aluminium fibre reinforced concrete. J King Saud Univ Eng Sci 33(1):23–29. https://doi.org/10.1016/j.jksues.2019.12.004

Nadia T, Zine EAR (2019) Valorization of aluminum waste on the Mechanical performance of mortar subject to cycles of freezer-thew. Procedia Comput Sci 158:1114–1121

Andrade C, Mynrine V, Da Silva D, Soares S, Simetti R, March F (2016) Compósito para a construção civil a partir de resíduos industriais. Revista Matéria 21(2):321–329

Bouglada MS, Ammar N, Larbi B (2021) Optimization of cellular concrete formulation with aluminum waste and mineral additions. Civil Eng J 7(7):1222–1234

Mehdi Zahrai S, Mortezagholi M, Najaf E (2016) Using AP2RC & P1RB micro-silica gels to improve concrete strength and study of resulting contamination. Adv Concret Construct 4(3):195–206

Najaf E, Orouji M, Mehdi Zahrai S (2022) Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber. De Gruyte 11(58–70):2022

Balamuralikrishnan R, Saravanan JR (2021) Effect of addition of alccofine on the compressive strength of cement mortar cubes. Emerg Sci J 5(2):155–170

Vladislav M, Mikhail L, Vladimir R, Kazimir R, Andrey I (2022) Influence of different types of aggregates on the structural properties of fiber-reinforced concrete. Lecture Notes Netw Syst 403(275189):1467–1476

Jagadale UT, Jadhav AB, Nayak CB (2022) Behaviour of ternary blended cement in M40 grade of concrete. J Emerg Technol Innov Res (JETIR) 9(6):159–166

Ravinder K (2016) Strength characteristics of Coca-Cola tin waste as fibres in concrete. Int J Adv Res Foundation 3(2):9–12

Liza N, Mohamad N, Salehuddi S, Che R, Afiza S, Roziana C (2013) the utilization of aluminum waste as sand replacement in concrete. Key Eng Mater 594–595:455–459

Ilya J, Cheow C (2017) Mechanical behaviour of fibre reinforced concrete using soft – drink can. Mater Sci Eng 271:1–6

Abbass W, Khan MI, Mourad S (2018) Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr Build Mater 168:556–569

Shakir R, Athab H, Abdulhameed Q (2018) Investigating the behavior of concrete and mortar reinforced with aluminum waste strips. Int J Eng Technol 7(437):211–213

Murali G, Vardhan CV, Prabu R, Khan ZM, Mohamed TA, Suresh T (2012) Experimental investigation on fibre reinforced concrete using waste materials. Int J Eng Res Appl 2(2):278–283

Rajaraman J (2017) Study on structural behavior of aluminium fiber in concrete. J Eng Appl Sci 12(11):9182–9183

Muwashee RS, Al-Jameel HA, Jabal QA (2018) Investigating the behavior of concrete and mortar reinforced with aluminum waste strips. Int J Eng Technology 7(437):211–213

Najaf E, Abbasi H, Mehdi Zahrai S (2022) Effect of waste glass powder, microsilica and polypropylene fibers on ductility, flexural and impact strengths of lightweight concrete. Int J Struct Integrity 13(1):1–24

Orouji M, Mehdi Zahrai S, Najaf E (2021) Effect of glass powder & polypropylene fibers on compressive and flexural strengths, toughness and ductility of concrete: an environmental approach. Structures 33:4616–4628

Channa IA, Saand A (2021) Mechanical behavior of concrete reinforced with waste aluminium strips. Civil Eng J 7(7):1–15

Nayak CB, Narule GN, Surwase HR (2022) Structural and cracking behaviour of RC T-beams strengthened with BFRP sheets by experimental and analytical investigation. J King Saud Univ Eng Sci 34(6):398–405

Nayak CB (2021) Experimental and numerical investigation on compressive and flexural behavior of structural steel tubular beams strengthened with AFRP composites. J King Saud Univ Eng Sci 33(2):88–94

Bengal SN, Pammar LS, Nayak CB (2022) Engineering application of organic materials with concrete: a review. Mater Today: Proceedings 56:581–586

Zanjad N, Pawar S, Nayak C (2022) Use of fly ash cenosphere in the construction Industry: a review. Mater Today: Proc 63:2185–2190

Nayak CB (2022) Experimental and numerical study on reinforced concrete deep beam in shear with crimped steel fiber. Innov Infrastruct Solutions 7(41):1–14

Suryawanshi NT, Suryawanshi NT, Thakare SB, Kate GK (2022) Optimization of self-cured high-strength concrete by experimental and grey Taguchi modelling. Iranian J Sci Technol, Trans Civil Eng 46(6):4313–4326

Kate GK, Nayak CB, Thakare SB (2021) Optimization of sustainable high-strength–high-volume fly ash concrete with and without steel fiber using Taguchi method and multi-regression analysis. Innov Infrastruct Solut 6(102):1–18

ASTM C125, (2013) Standard terminology relating to concrete and concrete aggregates, west Conshohocken: ASTM International

ASTM C136, (2001) Standard test method for sieve analysis of fine and coarse aggregates, West Conshohocken: ASTM International

Parlikar AS, Naik CV, Nayak CB (2021) An experimental study on effect of pharmaceutical industrial waste water on compressive strength of concrete. Int J Innov Res Sci Eng Technol (IJIRSET) 10(8):11068–11072

ASTM C1602M, (2006) Standard specification for mixing water used in the production of hydraulic cement concrete, West Conshohocken: ASTM International

ASTM A 820M, (2011) Standard Specification for steel fibers for fiber-reinforced concrete, West Conshohocken: ASTM International

Mediyanto A, Santosa B, Purwanto E (2019) Recovery compressive strength aluminum fiber lightweight concrete (with part of a roof tiles as coarse aggregate) after burning with a variation of water curing time. IOP Conference Series: Earth and Environmental 235:1–5

Barbosa de Oliveira MA, Soares Ramos EML, Carvalho de Oliveira DR, Pompeu Neto BB (2018) Análise da influência do formato de elemento de concreto e propriedades de fibras de aço na tenacidade à flexão. Matéria 23(3):1–14

American Concrete Institute 211.1, Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete, United States: American Concrete Institute, 2007

ASTM C150, (2012) Standard Specification for Portland Cement, West Conshohocken: ASTM International

ASTM C 192M, (2015) Standard practice for making and curing concrete test specimens in the laboratory, West Conshohocken: ASTM International

ASTM C143M, (2012) Standard test method for slump of hydraulic-cement concrete, West Conshohocken: ASTM International

ASTM C 1064M, (2005) Standard Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete, West Conshohocken: ASTM International

Shabbar R, Nedwell P, Wu Z (2017) Mechanical properties of lightweight aerated concrete with different aluminium powder content. Eco Sci Matec web of Conferences 120:1–7

ASTM C 231M, Standard test method for air content of freshly mixed concrete by the pressure method, West Conshohocken: ASTM International

Xianggang Z, Shuren W, Xiang G (2018) Mechanical properties of recycled aggregate concrete subjected to compression test. J Eng Sci Technol Rev 11(6):20–25

Bargherzadeh R, Sadeghi A-H, Latifi M (2011) Utilizing polypropylene fibers to improve physical and mechanical properties of concrete. Text Res J 82(1):88–96

Kett I (2010) Engineered concrete mix design and test method, 2da edn. Taylor & Francias Group, London

ASTM C 138M, (2014) Standard test method for density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete, West Conshohocken: ASTM International

Nayak CB, Taware PP, Jagadale UT, Jadhav NA, Morkhade SG (2022) Effect of SiO2 and ZnO Nano-composites on mechanical and chemical properties of modified concrete. Iranian J Sci Technol, Trans Civil Eng 46:1237–1247

Acknowledgements

We are grateful to the professional school of Civil Engineering of the Lord of Sipan University—Chiclayo for providing us with the advice to carry out this article.

Funding

None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muñoz Perez, S.P., Garcia Chumacero, J.M., Charca Mamani, S. et al. Influence of the secondary aluminum chip on the physical and mechanical properties of concrete. Innov. Infrastruct. Solut. 8, 45 (2023). https://doi.org/10.1007/s41062-022-01015-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-01015-3