Abstract

Metal nanoparticles (NP) and mesoporous (MP) oxides are complementary materials, since the size scale of pores in MP oxides matches that of NP and both systems have potential applications in similar fields. Besides, nanocomposites obtained through their combination possess not only the intrinsic properties of each component, but also new features derived from the synergy between them, mainly due to the high interfacial area between the metal and the oxide. Thus, new optical, catalytic and sensing properties can be achieved that are not easily available from the individual components. In this review, we focus our attention on such NP@MP composites, not only from the point of view of the most common synthesis pathways but also briefly describing their applications in fields as diverse as (photo)catalysis, sensing, photochromism and other optical properties, as well as patterning.

Similar content being viewed by others

1 Introduction

The renewed interest that metal nanoparticles (NP) have raised during the past decade has been motivated by their various special properties, which give rise to potential applications in diverse fields [1, 2], with a particularly strong focus on their catalytic and optical properties. The use of NP in catalysis is related in part to their high specific surface area but also to their high surface reactivity, which may drastically change as compared with their bigger counterparts [3, 4]. The field of NP catalysis is often termed “semi-heterogeneous catalysis”, as it is at the frontier between homogeneous and heterogeneous catalysis. NP catalysis has been applied for a large amount of organic reactions, but mainly in redox catalysis, photocatalysis (photocatalytic water splitting and photo-hydrogenation of alkenes, alkynes, and CO2), hydrogenation and oxidation [4]. On the other hand, the optical properties of NP are related to localized surface plasmon resonances (LSPR) [5, 6], which give rise to intense extinction bands in the visible and NIR, as well as high electric field enhancements at the NP surface [7]. The optical response of NP can be tuned by modifying their size and shape, as well as their dielectric environment (refractive index of the surrounding medium, presence of neighboring particles, etc.) [8]. These interesting optical properties make metal NP interesting for use in diverse fields such as (bio)sensors [9], surface enhanced Raman scattering (SERS) [10], production of devices that require light confinement (solar cells, vapor production, local heating, etc.) [11, 12] and biological applications (disease diagnosis and phototherapy, drug delivery, etc.) [12, 13].

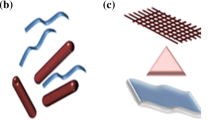

Due to the close relationship between synthesis, properties and applications, the synthesis of NP has been extensively developed during the last decades [1] and a wide variety of morphologies can be obtained in a reproducible way by means of colloid chemistry methods. Readily obtainable morphologies include spheres, nanorods, various polyhedra, nanostars and nanoplates [1, 14]. On the other hand, the synthesis of mesoporous (MP, pore diameters between 2 and 50 nm) oxides has also experienced an important development during the last 20 years. These materials are prepared combining the self-assembly of amphiphilic molecules (which act as templates) and sol–gel reactions (which give rise to the oxide), thereby leading to materials with extremely high specific surface area and highly ordered arrays of monodisperse pores. The field started its development with the MCM silica family [15], but an increasing amount of mesoporous materials with diverse chemical compositions, shaped as powders, monoliths, thin films, membranes, or fibers have also been developed [16–18]. MP oxide thin films (especially SiO2 and TiO2) are particularly interesting [19] because they can be easily extracted from a medium, thus rendering them ideal for applications that require reusability. Additionally, they show a high ability for integration in current material processing technologies, due to the high flexibility of its synthesis.

Metal NP and MP oxides can somehow complement each other, since the pores are complementary with the particles, both in size and potential applications. The obtained NP@MP composites possess the intrinsic properties of each family, but also new features derived from the synergy between the components, mainly due to the large interfacial area between the metal and the oxide. Powder NP@MP composites have been recently investigated in great detail, and several excellent reviews have been published on this subject [20, 21]. In this review, we focus our attention towards NP@MP composites prepared by combining MP oxide thin films and metal NP. We describe the most common synthesis methods as well as tested and potential applications.

2 Synthesis methods

Three general synthesis methods are commonly used for the preparation of NP@MP composite films. These methods are summarized in Fig. 1, and explained in this section.

2.1 Impregnation and reduction

The impregnation and reduction approach is, by far, the most common method for the preparation of NP@MP composite films. The general idea behind this process is depicted in Fig. 1a. In a first step, the MP films are prepared, usually by Evaporation Induced Self-Assembly [22], and the template is then eliminated by either thermal treatment or solvent extraction. Once the pores are emptied, the metal salt is adsorbed, which may involve electrostatic forces (for Ag(I) adsorption [23–30]), or specific interactions with amino groups (for Au(III)) [31–33], but trapping within polyelectrolyte brushes [34] has also been tested. In all cases, reduction of the metal ions into metallic particles is the last step. The reduction can be performed by thermal treatment [23], UV irradiation [27, 35–37] or by chemical reduction, using formaldehyde [38, 39], hydrogen gas [25, 29, 31, 32, 36, 40–42] or NaBH4 [30, 34, 39], among other reducing agents. It has been demonstrated that the NP size and spatial distribution within the film depends on the specific reducing treatment [28], particularly on the strength of the selected reducing agent. It should be noted that most often a single impregnation and reduction cycle is not sufficient to fill the pores completely, since the number of metal ions that can be adsorbed is limited. Nevertheless, the impregnation–reduction cycle can be repeated several times, which allows to control the amount of metal formed inside the pores. Interestingly, the final particle shape is determined by the pore size and connectivity. Thus, spherical NP are obtained in most cases, as can be seen in Fig. 2a. The main drawbacks of this approach are the lack of control in the location of the NP within the film and the formation of an unwanted metallic layer on top of the films [37, 39], but both problems can be overcome by modifying the synthesis procedure.

TEM images of different NP@MP composite films: a Ag NP@MP TiO2 obtained by impregnation and reduction (reproduced with permission from Ref. [38]. Copyright 2009 Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim); b Ag NP@MP SiO2 obtained by one-pot synthesis (Reproduced from Ref. [47] with permission from The Royal Society of Chemistry); c Au NP@MP SiO2 obtained using NP suspended in the sol (reproduced with permission from Ref. [48] Copyright © 2005 WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim); d Au NP@MP SiO2 obtained by adhesion of NP to a substrate followed by film deposition

A variation of this method is the electrochemically induced impregnation and reduction [24, 43–45]. In this case, the film is supported onto a conductive substrate, which is used as a working electrode. Subsequently, immersion in an Au(III) or Pt(IV) solution and application of an electrical potential leads to metal deposition. The metal may completely replicate the pore array, and it is even possible to dissolve the oxide leaving a metallic mesoporous material [44, 45]. Another variation of the method was proposed by Bois and coworkers [46], comprising the impregnation of Ag(I) in a mesostructured film (i.e., with the template still inside the pores). In this case, the metal is formed only on the topmost pore layer, which facilitates the control over the final particle shape by controlling the pore array, which is an interesting approach e.g. to obtain rod shaped NP. Further work to reproduce and expand these findings with MP films would be really interesting.

2.2 One pot synthesis

In this approach, a metal salt is included in the sol mixture that gives rise to the MP films, as shown in Fig. 1b. As the sols are highly acidic, the metal salt is stable under those conditions and the film deposition can be performed as usual. Both the oxide and the particles are formed at the same time under laser irradiation [49], X-ray irradiation [47, 50] or conventional thermal treatment [51–53]. Using this methodology, the obtained particles are small (due to the limited amount of metal salt that can be loaded in the sol) and are distributed both inside the oxide framework and at the surface of the pores. An example of a typical NP distribution is presented in Fig. 2b, where the small dark dots are Ag NP. In principle, due to their different localization, these NP are expected to be less accessible for chemical reactions, as compared to those obtained by the impregnation–reduction method, since a portion of the total metallic surface is covered by the oxide. However, no studies about this subject have been presented so far, rendering this topic an open question that should be studied in the future. Nevertheless, the method does provide a simple way to obtain metallic patterns inside the MP framework, as discussed in the applications section below.

2.3 Use of preformed particles

In all its variations, this method requires the preparation of metal NP by a colloid chemistry method before their incorporation within the film. Thus, both the size and shape of the NP can be defined prior to MP oxide synthesis and it is not restricted to spherical particles. However, these methods do not allow a high NP loading, as a consequence of the low NP concentrations in usual metal colloids.

2.3.1 Incorporation of particles within the sol

This method (schematically depicted in Fig. 1c.1) is rare, since metallic NP are usually unstable under the conditions required to prepare a stable sol (highly concentrated acidic medium, organic solvents). Consequently, this method requires a careful selection of the NP stabilizer, so as to make them compatible with the properties of the sols. Additionally, the NP size and shape should be controlled to allow formation of a smooth film, without cracks or thickness variations. An example of this method is the work by Goettmann et al. [48], who used Au NP stabilized by a phosphinine ligand to prepare composites with SiO2 MP films (Fig. 2c). The NP were introduced in the silica sol just before deposition in a mass ratio (calculated on the basis of the final SiO2 mass) of 0.5, 2, 5, and 10 % but only the samples with NP content below 2 % showed good optical quality. This work was later extended by the same group to Pd NP and MP TiO2 films [54]. Another approach was tested by Yang et al. [55], who included Au rods@SiO2 in a sol with silica precursors and obtained a composite in which the rods are first surrounded by a dense silica shell and then embedded in a MP film, which had been previously used for incorporation in standard silica gels [56, 57]. In this case however, access to the particles is severely restricted, since they are surrounded by a microporous silica shell.

2.3.2 Particle diffusion thorough the film

This method (depicted in Fig. 1c.2) is also unusual, since it requires the use of particles that are small enough to diffuse between the pores and the connecting necks [58, 59]. To improve diffusion, Patel et al. [60] used electrophoretic deposition to include 3.1 nm Au nanocrystals stabilized by dodecanethiol within TiO2 MP thin films (deposited onto a conductive substrate). With this methodology, Au nanocrystal loadings up to 21 wt% were reached. However, in all cases an irregular distribution along the film thickness was obtained, since the tortuosity of the MP films does not allow the diffusion of the particles to the innermost layer of pores.

2.3.3 Adhesion of particles to a substrate followed by film deposition

This method has been recently reported by our group [61–63] and represents a new approach that is schematically shown in Fig. 1c.3: a sub-monolayer of NP (spheres with different diameters, decahedra or other shapes) are chemically bound to a glass slide and subsequently covered with a MP thin film. The method allows obtaining fully covered metallic NP and well-ordered MP thin films. With this approach, the particles (whose shape and size can be finely tuned by well-known colloid chemistry methods) underneath the porous films remain accessible but not in direct contact with the medium, opening the way toward new applications. An example of this type of composites is presented in Fig. 2d. In a second step, the NP shape can be modified by seeded growth [62, 63], which allows obtaining either larger NP or even “hairy” NP (Fig. 3b), depending on the mesoporous material used and the growth conditions. By this procedure, it was possible to obtain novel NP shapes that are neither easily obtained in solution nor easily encapsulated within oxide films. Interestingly, such templated growth leads to intense and useful optical changes in the nanocomposite material (Fig. 3a).

3 Applications

Although the literature has so far mainly focused on synthetic methods to obtain NP@MP composites, several examples have also been presented on the possible applications of these materials. We review in the following subsections some of the most usual and (in our view) interesting applications.

3.1 Catalysis

In traditional catalysis of organic reactions by metals, inclusion of the NP inside MP films allows easy recovery and recycling of the catalyst [59] and may also influence the activity and selectivity of the reactions [64]. For example, Cortial et al. [54] tested Au NP@TiO2 as catalyst for glycol oxidation and Pd NP@SiO2 to catalyze the allylic amination of cinnamyl acetate by benzylamine. In the latter case, they found that immobilized NP were three orders of magnitude more active than their homogeneous counterparts and that the regioselectivity was totally in favor of one of the possible products. In the case of photocatalysis by semiconductors (SC), a synergic effect occurs: it has been demonstrated that metal NP can improve the electron flow from the SC surface to the metal, thereby suppressing electron–hole recombination, one of the main causes of activity loss of the photocatalysts. Thus, several groups tried to improve the photocatalytic activity of MP TiO2 by including Au or Ag NP in its framework or inside the pores of the MP oxides. For example, in a pioneering work by Stucky’s group [23], an apparent difference in the reaction mechanism and a higher apparent initial activity were reported upon incorporation of Ag NP in TiO2 MP films. Bannat et al. [24] demonstrated that Au can also improve the photocatalytic efficiency of TiO2, with almost no difference between composites prepared by impregnation–reduction and electrochemical methods. They found that, for photocatalytic NO oxidation, the presence of Au NP and dendritic nanostructures in the pores of TiO2 films substantially increases the photocatalytic activity by a factor of about 3 (from 15 to 40 % of the theoretical photon efficiency). A summary of these promising results is presented in Fig. 4.

Left Comparison of the photocatalytic activities of pristine and Au-loaded MP TiO2 films as well as commercial Sto Photosan. Right Cross-section TEM micrographs and optical images of the composite films prepared by impregnation and chemical (Au NP) or electrochemical reduction (Au NW). Adapted with permission from [24]. Copyright 2009 American Chemical Society

3.2 Sensors

NP@MP composites have been tested as sensors of different kinds, taking advantage of diverse characteristics of the composites. For example, our group used NP@MP composite films to follow the evaporation of solvents from the pores, by simple spectroscopic monitoring of changes in the LSPR band of Au nanodecahedra covered with different MP films (Fig. 5a) [61]. By using this synthesis path, the NP remain accessible to solvents and, as a consequence, their LSPR band can be spectrally shifted as the effective refractive index varies during evaporation of the solvent initially wetting the mesopores, as shown in Fig. 5b, c. The evaporation profile can then be related to the boiling point of the solvent, type of film, and accessibility of the NP. Therefore, these NP@MP composites can be used to study the interactions between a solvent and an oxide thin film.

a TEM image of Au decahedra covered with a SiO2 MP film; b Spectra of the material shown in a before (black curve) and after (red curve) toluene evaporation. c Δλmax(LSPR) as a function of time, during the evaporation of different solvents. Lines are guides for the eye. Adapted with permission from Ref. [61] Copyright 2010 American Chemical Society (Color figure online)

In a similar approach, Goettmann et al. [48] used Au NP (prepared ex situ and included in the sol just before film synthesis) embedded in MP SiO2 films to detect organic molecules (PMe3 and dodecanethiol) in solution, by following the LSPR band position. They also demonstrated that the system was selective toward small molecules, in principle due to the small pore size of the MP silica. Another recent application of the filtering ability of MP films has been reported, related to the exclusion of proteins from complex biological media, thereby facilitating the detection of small molecules by SERS [63]. In particular, 4-nitrobenzenethiol was clearly detected from a solution containing Bovine Serum Albumin (a usual serum protein) in buffer, without any contamination of the spectroscopic signal. In a related work, Malfatti et al. prepared SERS substrates from NP@MP composites [47] comprising the formation of metallic patterns inside the MP film by X-ray irradiation, so that a lab on a chip application can be envisioned for those composites. It is important to note that, although all these works are still closer to a proof-of-concept than to a real application, they are a promising first step of a novel approach that needs to be fully developed.

3.3 Optical properties

As discussed above, the preparation of NP@MP composites grants access to new properties due to the synergy between the components. In particular, the optical properties have been studied in detail, since they can have a key impact for the next generation of communication and information technology devices, as well as (bio)sensors and other biomedical products. We describe here a few selected studies regarding this subject.

3.3.1 Non linear optics

It has been demonstrated that NP incorporated in a dielectric matrix thin film present outstanding third-order optical nonlinearities [65]. These composites have been widely investigated due to their potential application in the next generation of optical communication and logical processing devices. Initially the composites were prepared by physical methods, such as co-sputtering, but suffered from drawbacks due to uncontrollable particle size and spatial distribution. Recently, several groups started to develop NP@MP thin film composites for non linear optics. By using these composites, it is possible to ensure a high dispersion and a good distribution uniformity of the NP in the films and thus, the nonlinear optical properties can be carefully controlled. With this approach, relatively high third order nonlinear optical susceptibilities (χ(3)) were obtained, by using Au@MP TiO2 [40, 66] and Au@MP SiO2 composites [31, 32, 41]; and it was even possible to control the χ(3) value by controlling the amount of Au incorporated in the matrix [32].

3.3.2 Photochromism

It is well known that photochromism (reversible change of color upon exposure to light) appears when Ag species interact with TiO2. The process is similar to that described in the catalysis section above: under UV irradiation electrons at the valence band of TiO2 are excited into the conduction band and then migrate toward Ag+ species, reducing them to Ag0. Then, the opposite reaction can occur: Ag NP interact with visible light through their LSPR and electrons migrate to the conduction band of TiO2, which induces the oxidation of Ag0 to Ag+ [39]. The whole process is accompanied by a color change and therefore this property can be exploited in the design of optical data storage and display devices. The use of Ag@MP TiO2 for this purpose was first demonstrated by Bois and collaborators in 2009 [39]. They observed the disappearance of the color associated to the LSPR band upon irradiation with visible light, which was then applied to “write” and “erase” Ag NP within MP TiO2 by using UV and visible light (see Fig. 6). Interestingly, they found that at low irradiance, selective oxidation occurs leading to changes in the film color according to the wavelength used; whereas at higher irradiance, the oxidation of large NP is accompanied by the formation of many small NP in their vicinity, which provides the films with the same color for all tested wavelengths [35].

a Ag dot printed onto a TiO2 MP film by irradiation at 244 nm for 150 ms with an intensity below the threshold (30 kW cm−2) and b erased. c UV-printed dot (a) locally erased by a focused 488 nm-wavelength beam. d Words successively printed at 244 nm (30 kW cm−2 for 150 ms) and erased at 488 nm at the same place. The films are observed in reflection with an optical microscope. Reproduced with permission from Ref. [35]. Copyright © 2010 WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim

3.3.3 Emission enhancement

Noble metal NP can cause significant changes in the fluorescence behavior of adjacent fluorophores. This phenomenon is also present when the fluorophores are included within a MP matrix, and thus it has been measured for NP@MP composite films. As an example, Leroy et al. [67] demonstrated that the introduction of Ag NP can enhance the photoluminescence emission intensity of Eu3+ embedded in MP ZrO2, probably due to energy transfer from Ag NP to Eu3+ or/and change of radiative decay rates. This is an interesting result, because these lanthanide doped ZrO2 matrices are promising for optical amplification and light waveguides. Other groups have reported related results, such as rhodamine 6G photoluminescence enhancement (by a factor of 3) in Ag@Ti doped MP SiO2 films [26] and fluorescence enhancement of organic fluorophores generated by Au nanorods embedded in MP SiO2 films [55].

3.4 Patterning

Au(III)@MP SiO2 [50] and Ag(I)@MP SiO2 [47] composites were synthesized by Innocenzi’s group by means of a one-pot route. By Deep X-ray Lithography (performed in a synchrotron source), they managed to obtain metallic (Au or Ag) NP embedded within the film, only in the irradiated region. As X-rays also condense the inorganic framework, the method allows for the preparation of 3D MP structures onto a substrate. In a related approach, Martínez et al. [27] prepared Ag@MP TiO2 composites by UV-exposure of Ag(I) impregnated MP TiO2 using a conventional lithography mask. Patterns could be obtained (see Fig. 7) with arbitrary shapes in the submicron scale, rendering this method very powerful, as it is fully compatible with the techniques and substrates currently used in the sensors and microelectronics industry. Conductivity measurements [68] were performed in these composites and the results indicated a 3-dimensional connectivity between the embedded Ag NP.

Reduction of Ag+ by UV-light in TiO2 MP films, using different masks to pattern the infiltration. a Optical image of the composite after 1 min of exposure. b SEM image of the sample shown in a. c Images of patterned composites, showing the increase in the amount of Ag incorporated as a function of irradiation time. a and b are reproduced with permission from Ref. [27], Copyright 2009 American Chemical Society

Additionally, as described in Sect. 3.3.2 and shown in Fig. 5, it is also possible to create dot patterns by using irradiation with UV light without masks [35]. Despite only being the first steps, these studies pave the way toward the integration of MP films and NP@MP nanocomposites into real devices.

4 Outlook and perspectives

It is clear that the synthesis of NP@MP composite films is nowadays sufficiently well developed, and several methods are readily available to researchers. The variety of synthesis approaches offers several possible configurations, in which the composites may contain the NP inside the pores of MP oxides, but also included in the oxide framework or completely covered by the film. Interesting post-synthesis (templated) growth processes have also been devised, which allow exploiting the pore architecture to obtain new properties for the metallic component. Thus, the design of NP@MP composite films can be easily varied according to the desired application. Although the synthesis methods are settled and understood from the basic point of view, the applications of these composites are still under development. Several interesting seminal works have been presented and reviewed in this article, but a lot of work remains to be performed until useful devices are fully developed. Even though we have only discussed a few applications in catalysis and plasmonics, other fields may readily benefit from the special properties of these nanocomposites, such as environmental remediation or surface protection, among others. We expect that advancements in these areas and most probably many others will be reported in years to come.

References

Xia Y, Xiong Y, Lim B, Skrabalak SE (2009) Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics? Angew Chem Int Ed 48(1):60–103. doi:10.1002/anie.200802248

Daniel M-C, Astruc D (2003) Gold nanoparticles: assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem Rev 104(1):293–346. doi:10.1021/cr030698+

Schätz A, Reiser O, Stark WJ (2010) Nanoparticles as semi-heterogeneous catalyst supports. Chem Eur J 16(30):8950–8967. doi:10.1002/chem.200903462

Astruc D, Lu F, Aranzaes JR (2005) Nanoparticles as recyclable catalysts: the frontier between homogeneous and heterogeneous catalysis. Angew Chem Int Ed 44(48):7852–7872. doi:10.1002/anie.200500766

Bohren CF, Huffman DR (1983) Absorption and scattering of light by small particles. Wiley science paperback series. Wiley-Interscience, New York

Kreibig U, Vollmer M (1995) Optical properties of metal clusters. Springer series in materials science. Springer, Berlin

Moores A, Goettmann F (2006) The plasmon band in noble metal nanoparticles: an introduction to theory and applications. New J Chem 30(8):1121–1132. doi:10.1039/B604038C

Liz-Marzán LM (2006) Tailoring surface plasmons through the morphology and assembly of metal nanoparticles. Langmuir 22(1):32–41. doi:10.1021/la0513353

Sepúlveda B, Angelomé PC, Lechuga LM, Liz-Marzán LM (2009) LSPR-based nanobiosensors. Nano Today 4(3):244–251. doi:10.1016/j.nantod.2009.04.001

Alvarez-Puebla RA, Liz-Marzán LM (2010) SERS-based diagnosis and biodetection. Small 6(5):604–610. doi:10.1002/smll.200901820

Atwater HA, Polman A (2010) Plasmonics for improved photovoltaic devices. Nat Mater 9(3):205–213. doi:10.1038/nmat2629

Sperling RA, Rivera Gil P, Zhang F, Zanella M, Parak WJ (2008) Biological applications of gold nanoparticles. Chem Soc Rev 37(9):1896–1908. doi:10.1039/B712170A

Doane TL, Burda C (2012) The unique role of nanoparticles in nanomedicine: imaging, drug delivery and therapy. Chem Soc Rev 41(7):2885–2911. doi:10.1039/c2cs15260f

Grzelczak M, Pérez-Juste J, Mulvaney P, Liz-Marzán LM (2008) Shape control in gold nanoparticle synthesis. Chem Soc Rev 37(9):1783–1791. doi:10.1039/B711490G

Kresge CT, Leonowicz ME, Roth WJ, Vartuli JC, Beck JS (1992) Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature 359:710–712. doi:10.1038/359710a0

Sánchez C, Boissière C, Grosso D, Laberty C, Nicole L (2008) Design, synthesis, and properties of inorganic and hybrid thin films having periodically organized nanoporosity. Chem Mater 20(3):682–737. doi:10.1021/cm702100t

Soler-Illia GJAA, Sanchez C, Lebeau B, Patarin J (2002) Chemical Strategies to design textured materials: from microporous and mesoporous oxides to nanonetworks and hierarchical structures. Chem Rev 102(11):4093–4138. doi:10.1021/cr0200062

Kresge CT, Roth WJ (2013) The discovery of mesoporous molecular sieves from the twenty year perspective. Chem Soc Rev 42(9):3663–3670. doi:10.1039/c3cs60016e

Innocenzi P, Malfatti L (2013) Mesoporous thin films: properties and applications. Chem Soc Rev 42(9):4198–4216. doi:10.1039/c3cs35377j

Wang Q, Shantz DF (2008) Ordered mesoporous silica-based inorganic nanocomposites. J Solid State Chem 181(7):1659–1669. doi:10.1016/j.jssc.2008.06.015

White RJ, Luque R, Budarin VL, Clark JH, Macquarrie DJ (2009) Supported metal nanoparticles on porous materials. Methods and applications. Chem Soc Rev 38(2):481–494. doi:10.1039/B802654H

Brinker CJ, Lu Y, Sellinger A, Fan H (1999) Evaporation-induced self-assembly: nanostructures made easy. Adv Mater 11(7):579–585. doi:10.1002/(SICI)1521-4095(199905)11:7<579::AID-ADMA579>3.0.CO;2-R

Andersson M, Birkedal H, Franklin NR, Ostomel T, Boettcher S, Palmqvist AEC, Stucky GD (2005) Ag/AgCl-loaded ordered mesoporous anatase for photocatalysis. Chem Mater 17(6):1409–1415. doi:10.1021/cm0485761

Bannat I, Wessels K, Oekermann T, Rathousky J, Bahnemann D, Wark M (2009) Improving the photocatalytic performance of mesoporous titania films by modification with gold nanostructures. Chem Mater 21(8):1645–1653. doi:10.1021/cm803455k

Besson S, Gacoin T, Ricolleau C, Boilot J-P (2003) Silver nanoparticle growth in 3D-hexagonal mesoporous silica films. Chem Comm 3:360–361. doi:10.1039/b208357d

Horiuchi Y, Shimada M, Kamegawa T, Mori K, Yamashita H (2009) Size-controlled synthesis of silver nanoparticles on Ti-containing mesoporous silica thin film and photoluminescence enhancement of rhodamine 6G dyes by surface plasmon resonance. J Mater Chem 19(37):6745–6749. doi:10.1039/b910474g

Martínez ED, Bellino MG, Soler-Illia GJAA (2009) Patterned production of silver–mesoporous titania nanocomposite thin films using lithography-assisted metal reduction. ACS Appl Mater Interfaces 1(4):746–749. doi:10.1021/am900018j

Nadar L, Sayah R, Vocanson F, Crespo-Monteiro N, Boukenter A, Sao Joao S, Destouches N (2011) Influence of reduction processes on the colour and photochromism of amorphous mesoporous TiO2 thin films loaded with a silver salt. Photochem Photobiol Sci 10(11):1810–1816. doi:10.1039/c1pp05172e

Plyuto Y, Berquier J-M, Jacquiod C, Ricolleau C (1999) Ag nanoparticles synthesised in template-structured mesoporous silica films on a glass substrate. Chem Comm 17:1653–1654. doi:10.1039/a904681j

Qi H, Shopsowitz KE, Hamad WY, MacLachlan MJ (2011) Chiral nematic assemblies of silver nanoparticles in mesoporous silica thin films. J Am Chem Soc 133(11):3728–3731. doi:10.1021/ja110369d

Gu J-L, Shi J-L, You G-J, Xiong L-M, Qian S-X, Hua Z-L, Chen H-R (2005) Incorporation of highly dispersed gold nanoparticles into the pore channels of mesoporous silica thin films and their ultrafast nonlinear optical response. Adv Mater 17(5):557–560. doi:10.1002/adma.200401085

Lu Q, Cui F, Dong C, Hua Z, Shi J (2011) Gold nanoparticles incorporated mesoporous silica thin films of varied gold contents and their well-tuned third-order optical nonlinearities. Opt Mater 33(8):1266–1271. doi:10.1016/j.optmat.2011.02.024

Petkov N, Platschek B, Morris MA, Holmes JD, Bein T (2007) Oriented Growth of Metal and Semiconductor Nanostructures within Aligned Mesoporous Channels. Chem Mater 19(6):1376–1381. doi:10.1021/cm0627239

Calvo A, Fuertes MC, Yameen B, Williams FJ, Azzaroni O, Soler-Illia GJAA (2010) Nanochemistry in confined environments: polyelectrolyte brush-assisted synthesis of gold nanoparticles inside ordered mesoporous thin films. Langmuir 26(8):5559–5567. doi:10.1021/la9038304

Crespo-Monteiro N, Destouches N, Bois L, Chassagneux F, Reynaud S, Fournel T (2010) Reversible and irreversible laser microinscription on silver-containing mesoporous titania films. Adv Mater 22(29):3166–3170. doi:10.1002/adma.201000340

Fukuoka A, Araki H, Sakamoto Y, Sugimoto N, Tsukada H, Kumai Y, Akimoto Y, Ichikawa M (2002) Template synthesis of nanoparticle arrays of gold and platinum in mesoporous silica films. Nano Lett 2(7):793–795. doi:10.1021/nl0256107

Kumai Y, Tsukada H, Akimoto Y, Sugimoto N, Seno Y, Fukuoka A, Ichikawa M, Inagaki S (2006) Highly ordered platinum nanodot arrays with cubic symmetry in mesoporous thin films. Adv Mater 18(6):760–762. doi:10.1002/adma.200502184

Fuertes MC, Marchena M, Marchi MC, Wolosiuk A, Soler-Illia GJAA (2009) Controlled deposition of silver nanoparticles in mesoporous single- or multilayer thin films: from tuned pore filling to selective spatial location of nanometric objects. Small 5(2):272–280. doi:10.1002/smll.200800894

Bois L, Chassagneux F, Battie Y, Bessueille F, Mollet L, Parola S, Destouches N, Toulhoat N, Moncoffre N (2009) Chemical growth and photochromism of silver nanoparticles into a mesoporous titania template. Langmuir 26(2):1199–1206. doi:10.1021/la902339j

Cui F, Hua Z, Wei C, Li J, Gao Z, Shi J (2009) Highly dispersed Au nanoparticles incorporated mesoporous TiO2 thin films with ultrahigh Au content. J Mater Chem 19(41):7632–7637. doi:10.1039/B912016E

Fang J-Y, Qin S-Q, Zhang X-A, Nie Y-M, Wang F (2012) Linear and nonlinear optical properties of gold nanocrystal-incorporated mesoporous silica thin films. RSC Adv 2(31):11777–11785. doi:10.1039/c2ra21395h

Zhang Y, Yuwono AH, Li J, Wang J (2008) Highly dispersed gold nanoparticles assembled in mesoporous titania films of cubic configuration. Micropor Mesopor Mater 110(2–3):242–249. doi:10.1016/j.micromeso.2007.06.009

Pérez MD, Otal E, Bilmes SA, Soler-Illia GJAA, Crepaldi EL, Grosso D, Sanchez C (2004) Growth of gold nanoparticle arrays in TiO2 mesoporous matrixes. Langmuir 20(16):6879–6886. doi:10.1021/la0497898

Wu C-W, Yamauchi Y, Ohsuna T, Kuroda K (2006) Structural study of highly ordered mesoporous silica thin films and replicated Pt nanowires by high-resolution scanning electron microscopy (HRSEM). J Mater Chem 16(30):3091–3098. doi:10.1039/b604062d

Kanno Y, Suzuki T, Yamauchi Y, Kuroda K (2012) Preparation of Au nanowire films by electrodeposition using mesoporous silica films as a template: vital effect of vertically oriented mesopores on a substrate. J Phys Chem C 116(46):24672–24680. doi:10.1021/jp308772b

Bois L, Chassagneux F, Desroches C, Battie Y, Destouches N, Gilon N, Parola S, Stéphan O (2010) Electroless growth of silver nanoparticles into mesostructured silica block copolymer films. Langmuir 26(11):8729–8736. doi:10.1021/la904491v

Malfatti L, Falcaro P, Marmiroli B, Amenitsch H, Piccinini M, Falqui A, Innocenzi P (2011) Nanocomposite mesoporous ordered films for lab-on-chip intrinsic surface enhanced Raman scattering detection. Nanoscale 3(9):3760–3766. doi:10.1039/C1NR10404G

Goettmann F, Moores A, Boissière C, Le Floch P, Sanchez C (2005) A selective chemical sensor based on the plasmonic response of phosphinine-stabilized gold nanoparticles hosted on periodically organized mesoporous silica thin layers. Small 1(6):636–639. doi:10.1002/smll.200500037

Battie Y, Destouches N, Bois L, Chassagneux F, Tishchenko A, SP Parola, Boukenter A (2010) Growth mechanisms and kinetics of photoinduced silver nanoparticles in mesostructured hybrid silica films under UV and visible illumination. J Phys Chem C 114(19):8679–8687. doi:10.1021/jp9046903

Malfatti L, Marongiu D, Costacurta S, Falcaro P, Amenitsch H, Marmiroli B, Grenci G, Casula MF, Innocenzi P (2010) Writing self-assembled mesostructured films with in situ formation of gold nanoparticles. Chem Mater 22(6):2132–2137. doi:10.1021/cm902625v

Chassagneux F, Simon J-P, Bois L, Desroches C, Brioude A (2011) Reorganization induced by silver salt reduction inside a mesostructured block copolymer silica film. J Phys Chem C 115(51):25201–25208. doi:10.1021/jp207207x

Gu J, Shi J, Xiong L, Chen H, Ruan M (2004) A new strategy to incorporate highly dispersed nanoparticles into the pore channels of mesoporous silica thin films. Micropor Mesopor Mater 74(1–3):199–204. doi:10.1016/j.micromeso.2004.06.019

Krylova GV, Gnatyuk YI, Smirnova NP, Eremenko AM, Gun’ko VM (2009) Ag nanoparticles deposited onto silica, titania, and zirconia mesoporous films synthesized by sol–gel template method. J Sol–Gel Sci Technol 50(2):216–228. doi:10.1007/s10971-009-1954-x

Cortial G, Siutkowski M, Goettmann F, Moores A, Boissière C, Grosso D, Le Floch P, Sanchez C (2006) Metallic nanoparticles hosted in mesoporous oxide thin films for catalytic applications. Small 2(8–9):1042–1045. doi:10.1002/smll.200600154

Yang Z, Ni W, Kou X, Zhang S, Sun Z, Sun L-D, Wang J, Yan C-H (2008) Incorporation of gold nanorods and their enhancement of fluorescence in mesostructured silica thin films. J Phys Chem C 112(48):18895–18903. doi:10.1021/jp8069699

Kobayashi Y, Correa-Duarte MA, Liz-Marzán LM (2001) Sol–gel processing of silica-coated gold nanoparticles. Langmuir 17(20):6375–6379. doi:10.1021/la010736p

Pérez-Juste J, Correa-Duarte MA, Liz-Marzán LM (2004) Silica gels with tailored, gold nanorod-driven optical functionalities. Appl Surf Sci 226(1–3):137–143. doi:10.1016/j.apsusc.2003.11.013

May RA, Patel MN, Johnston KP, Stevenson KJ (2009) Flow-based multiadsorbate ellipsometric porosimetry for the characterization of mesoporous Pt–TiO2 and Au–TiO2 nanocomposites. Langmuir 25(8):4498–4509. doi:10.1021/la8038158

Mitra A, Jana D, De G (2012) A facile synthesis of cubic Im(-3)m alumina films on glass with potential catalytic activity. Chem Comm 48(27):3333–3335. doi:10.1039/c2cc18053g

Patel MN, Williams RD, May RA, Uchida H, Stevenson KJ, Johnston KP (2008) Electrophoretic deposition of Au nanocrystals inside perpendicular mesochannels of TiO2. Chem Mater 20(19):6029–6040. doi:10.1021/cm8012705

Angelomé PC, Liz-Marzán LM (2010) Monitoring solvent evaporation from thin films by localized surface plasmon resonance shifts. J Phys Chem C 114(43):18379–18383. doi:10.1021/jp106528n

Angelomé PC, Pastoriza-Santos I, Pérez Juste J, Rodríguez-González B, Zelcer A, Soler-Illia GJAA, Liz Marzán LM (2012) Growth and branching of gold nanoparticles through mesoporous silica thin films. Nanoscale 4:931–939. doi:10.1039/c2nr11547f

López-Puente V, Abalde-Cela S, Angelomé PC, Alvarez-Puebla RA, Liz-Marzán LM (2013) Plasmonic mesoporous composites as molecular sieves for SERS detection. J Phys Chem Lett 2715–2720. doi:10.1021/jz4014085

Muraza O, Rebrov EV, Berenguer-Murcia A, de Croon MHJM, Schouten JC (2009) Selectivity control in hydrogenation reactions by nanoconfinement of polymetallic nanoparticles in mesoporous thin films. Appl Catal A 368(1–2):87–96. doi:10.1016/j.apcata.2009.08.014

Hamanaka Y, Fukuta K, Nakamura A, Liz-Marzán LM, Mulvaney P (2004) Enhancement of third-order nonlinear optical susceptibilities in silica-capped Au nanoparticle films with very high concentrations. Appl Phys Lett 84(24):4938–4940

Cui F, Feng C, Xie R, Hua Z, Cui X, Zhou J, Wei C, Ohtsuka H, Sakka Y, Shi J (2010) Significant third-order optical nonlinearity enhancement of gold nanoparticle incorporated mesoporous silica thin films by magnetic field thermal treatment. J Mater Chem 20(38):8399–8404. doi:10.1039/c0jm00886a

Leroy CM, Cardinal T, Jubera V, Aymonier C, Treguer-Delapierre M, Boissière C, Grosso D, Sanchez C, Viana B, Pellé F (2013) Luminescence properties of ZrO2 mesoporous thin films doped with Eu3+ and Agn. Micropor Mesopor Mater 170:123–130. doi:10.1016/j.micromeso.2012.11.014

Martínez ED, Granja L, Bellino MG, Soler-Illia GJAA (2010) Electrical conductivity in patterned silver–mesoporous titania nanocomposite thin films: towards robust 3D nano-electrodes. Phys Chem Chem Phys 12(43):14445–14448. doi:10.1039/C0CP00824A

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Angelomé, P.C., Liz-Marzán, L.M. Synthesis and applications of mesoporous nanocomposites containing metal nanoparticles. J Sol-Gel Sci Technol 70, 180–190 (2014). https://doi.org/10.1007/s10971-013-3238-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3238-8