Abstract

Industrial process plants are increasingly becoming complex structures with high level of automation. Nonetheless, the final plant productivity and the overall equipment efficiency does not solely depend on an optimized engineering design/installation practice, but also on human operators supervision. In parallel, along with the classic demand to minimize costs and time-to-market during the design phases, issues concerning human safety and failure prevention play a crucial role, one of the highest target being the avoidance of dangerous process states. Within this context, Simulation-Based-Training (SBT) allows plant operators to learn how to command complex automated machineries within a secure virtual environment. Similar to its usage in medical, aerospace, naval and military fields, SBT for manufacturing systems can be employed in order to involve the user within a realistic scenario, thus providing an effective, lifelike, interactive training experience under the supervision of experienced personnel. In addition, also according to previous literature, industry-driven SBT may be effectively envisaged as a natural extension of the plant life-cycle simulation practice, comprising Design Simulation & Optimization, Virtual Commissioning, Operator Training, up to Plant Maintenance. In this context, since the overall system behavior depends both on manufacturing process dynamics and Control Logics, the main challenge for an effective SBT is related with the development of a real-time environment where control system responsiveness is fully reproduced. Owing to this consideration, this paper reports a successful industrial case study, concerning a novel SBT workbench used for steel plants operator training, discussing both the virtual prototyping phase and the development of a real-time simulation architecture. In particular, a hybrid process simulation is employed, where a virtual process model is coupled with physical PLC and Human–Machine Interface, thus achieving an accurate reproduction of the real plant/operator interaction.

Similar content being viewed by others

References

Garza-Reyes, A.J., Eldridge, S., Barber, K.D., Soriano-Meier, H.: Overall equipment effectiveness (OEE) and process capability (PC) measures. Int. J. Qual. Reliab. Manag. 27(1), 48–62 (2010)

Chand, G., Shirvani, B.: Implementation of TPM in cellular manufacture. J. Mater. Process. Technol. 103(1), 149–154 (2000)

O’Hara, J.M., Hall, R.E.: Advanced control rooms and crew performance issues: implications for human reliability. IEEE Trans. Nucl. Sci. 39(4), 919–923 (1992)

Parasuraman, R., Sheridan, T.B., Wickens, C.D.: A model for types and levels of human interaction with automation. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 30(3) (2000)

VDMA–Packaging Machinery Association: DIN 8743: Packaging machines and packaging installations, time related definitions, reference factors and calculation fundamentals, available online (2005)

Lim, T.G., Reeu, C.W.: Development of human–machine interface for automatic control of electro-slag remelting process. In: Proceedings of 37th IAS Annual Meeting Industry Applications Conference

Chao, G.: Human–machine interface: design principles of visual information in human-machine interface design. In: Proceedings of International Conference on Intelligent Human–Machine Systems and Cybernetics, vol. 2, pp. 262–265, Hangzhou, Zhejiang, China (2009)

Bradshaw, J.M., Dignum, V., Jonker, C., Sierhuis, M.: Human–agent–robot teamwork. IEEE Intell. Syst. 27(2), 8–13 (2012)

Stork, S., Stößel, C., Schubö, A.: Optimizing human–machine interaction in manual assembly. In: Proceedings of The 17th IEEE International Symposium on Robot and Human Interactive Communication, pp. 113–118, Munich, Germany (2008)

Bolton, M.L., Bass, E.J., Siminiceanu, R.I.: Using formal verification to evaluate human-automation interaction: a review. IEEE Trans. Syst. Man Cybern. Syst. 43(3), 488–503 (2013)

O’Hara, J.M., Higgins, J.C., Brown, W.S., Fink, R.: Human factors considerations with respect to emerging technology in nuclear power plants, U.S. Nuclear Regulatory Commission, Washington, DC, BNL Tech. Report 79947–2008, 20555–0001 (2008)

Nachreiner, F., Nickel, P., Meyer, I.: Human factors in process control systems: the design of human-machine interfaces. Saf. Sci. 44(1), 5–26 (2006)

Flach, J.M.: The human as a critical component in an adaptive meaning processing system. Proc. IEEE Int. Conf. Syst. Man Cybern. 3, 2586–2591 (2004)

Elzer, P., Weisang, C., Zinser, K.: Knowledge-based system support for operator tasks in S&C environments. In: Proceedings of IEEE International Conference on Systems, Man and Cybernetics, vol. 3, pp. 1078–1083, Cambridge, MA, USA (1989)

Dauphinee, J.L.: Development and implementation of a sustainable operator training and certification process. In: Proceedings of IEEE International Semiconductor Manufacturing Symposium, pp. 509–512, San Jose, CA, USA (2001)

Stone, R.: Virtual reality for interactive training: an industrial practitioner’s viewpoint. Int. J. Hum. Comput. Stud. 55, 699–711 (2001)

Salas, E., Rosen, M.A., Held, J.D., Weissmuller, J.J.: Performance measurement in simulation-based training: a review and best practices. Simul. Gaming 40, 328–376 (2009)

Bell, B.S., Kanar, A.M., Kozlowski, S.W.J.: Current issues and future directions in simulation-based training in North America. Int. J. Hum. Resour. Manag. 19(8), 1416–1434 (2008)

Lian-Yi, C., Fujimoto, H., Miwa, K., Abe, T., Sumi, A., Ito, Y.: A dental training system using virtual reality. Proc. IEEE Int. Symp. Comput. Intell. Robot. Autom. 1, 430–434 (2003)

Violante, M.G., Vezzetti, E.: Design and implementation of 3D Web-based interactive medical devices for educational purposes. Int. J. Interact. Design Manuf. 1–14 (2015). doi:10.1007/s12008-015-0277-0

Loftin, R.B.: Virtual environments for aerospace training. In: Proceedings of IEEE Technical Applications Conference and Workshops Northcon, Portland, OR, USA (1995)

De Filippo, F., Stork, A., Schmedt, H., Bruno, F.: A modular architecture for a driving simulator based on the FDMU approach. Int. J. Interact. Design Manuf. 8, 139–150 (2014)

Isermann, R.: Mechatronic systems–a challenge for control engineering. In: Proceedings of the American Control Conference, vol. 5, pp. 2617–2632, Albuquerque, New Mexico, USA

Oppelt, M., Wolf, G., Urbas, L.: Towards an integrated use of simulation within the life-cycle of a process plant–a prototypical implementation. In: IEEE 20th Conference on Emerging Technologies & Factory Automation (ETFA), pp. 1–8 (2015)

Oppelt, M., Barth, M., Graube, M., Urbas, L.: Enabling the integrated use of simulation within the life cycle of a process plant: an initial roadmap: results of an in-depth online study. Proceeding of IEEE International Conference on Industrial Informatics, INDIN, art. 7281709, 49–55 (2015)

Oppelt, M., Urbas, L.: Integrated virtual commissioning an essential activity in the automation engineering process: from virtual commissioning to simulation supported engineering. In: Proceedings of the 40th Annual Conference of the IEEE Industrial Electronics Society, art. no. 7048867, pp. 2564–2570 (2014)

Bausa, J., Dünnebier, G.: Life Cycle Modelling in the chemical industries: is there any reuse of models in automation and control?. In: Proceedings of the 16th European Symposium on Computer Aided Process Engineering and 9th Int. Symposium on Process Systems Engineering, pp. 3–8 (2006)

Engl, G., Kröner, A., Pottmann, M.: Practical aspects of dynamic simulation in plant engineering. In: Proceedings of the 20th European Symposium on Computer Aided Process Engineering, ESCAPE20 (2010)

Gu, F., Harrison, W.S., Tilbury, D.M., Yuan, C.: Hardware-in-the-loop for manufacturing automation control: current state and identified needs. In: Proceedings of the 3rd Annual IEEE Conference on Automation Science and Engineering, pp. 1105–1110 (2007)

Hoffmann, P., Schumann, R., Maksoud, T.M.A., Premier, G.C.: Virtual commissioning of manufacturing systems a review and new approaches for simplification. In: Proceedings 24th European Conference on Modelling and Simulation (2010)

Hincapié, M., de Jesús Ramírez, M., Valenzuela, A., Valdez, J.A.: Mixing real and virtual components in automated manufacturing systems using PLM tools. Int. J. Interact. Design Manuf. 8(3), 209–230 (2014)

Bohlmann, S., Becker, M., Balci, S., Szczerbicka, H.: Online simulation based decision support system for resource failure management in multi-site production environments. In: Proceedings of the 18th IEEE International Conference on Emerging Technologies and Factory Automation (2013)

Reinhart, G., Wünsch, G.: Economic application of virtual commissioning to mechatronic production systems. Prod. Eng. 1, 371–379 (2007)

Drath, R., Weber, P., Mauser, N.: An evolutionary approach for the industrial introduction of virtual commissioning. In: Proceedings of IEEE International Conference on Emerging Technologies and Factory Automation, pp. 5–8, Hamburg, Germany (2008)

Briand, R., Fischer, X., Arrijuria, O., Terrasson, G.: Multidisciplinary design process based on virtual prototyping for microsystem design. Virtual Phys. Prototyp. 5(3), 153–162 (2010)

Legardeur, J., Merlo, C., Fischer, X.: An integrated information system for product design assistance based on artificial intelligence and collaborative tools. Int. J. Product Lifecycle Manag. 1(3), 211–229 (2006)

Fischer, X., Nadeau, J.: 2006 Research in Interactive Design—Virtual, Interactive and Integrated Product Design and Manufacturing for Industrial Innovation, vol. 3, Springer, France (2011)

MacDiarmid, M., Bacic, M.: Quantifying the accuracy of hardware-in-the-loop simulations. In: Proceedings of American Control Conference, pp. 5147–5152, New York, NY, USA (2007)

Read, P., Meyer, M.P.: Restoration of motion picture film, In: Butterworth-Heinemann Series in Conservation and Museology, pp. 24–26 (2000)

Harrison, W.S., Tilbury, D.M., Yuan, C.: From hardware-in-the-loop to hybrid process simulation: an ontology for the implementation phase of a manufacturing system. IEEE Trans. Autom. Sci. Eng. 9(1), 96–109 (2012)

http://w3.siemens.com/mcms/programmable-logic-controller/en/advanced-controller/s7-400/pages/default.aspx. Accessed 28 Oct 2016

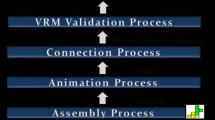

Ahmad, M., Ahmad, B., Harrison, R., Alkan, B., Vera, D., Meredith, J.O., Bindel, A.: A framework for automatically realizing assembly sequence changes in a virtual manufacturing environment. Procedia CIRP 50, 129–134 (2016)

Lee, C.G., Park, S.C.: Survey on the virtual commissioning of manufacturing systems. J. Comput. Design Eng. 1(3), 213–222 (2014)

Delmia 3D digital manufacturing solution, Dassault Systems. http://www.3ds.com/products-services/delmia/

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vergnano, A., Berselli, G. & Pellicciari, M. Interactive simulation-based-training tools for manufacturing systems operators: an industrial case study. Int J Interact Des Manuf 11, 785–797 (2017). https://doi.org/10.1007/s12008-016-0367-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-016-0367-7