Abstract

Advances in manufacturing technologies and computational engineering are key enablers for optimized designs necessary for product performance improvements. Amongst other manufacturing technologies, particularly Additive Manufacturing (AM) is pushing the envelope of feasible design complexity challenging design engineers as well as their Computer-Aided Design (CAD) tools. The research field of Design for Additive Manufacturing (DfAM) provides an exhaustive supply of specific engineering design knowledge and methodological approaches accordingly. To enable design engineers to put those approaches into practice, this research gathers and structures not yet addressed AM-related requirements on the state of the art CAD tools. Additionally, architectural CAD functions as well as features are being pointed out and envisioned design workflow adaptions introduced, necessary to enable engineers to holistically utilize AM design potentials with CAD systems of the mid-term future.

Similar content being viewed by others

1 Introduction

Product development has changed considerably in recent decades, amongst others, as a result of technical progress. Computer technology has made a major contribution here, increasingly digitizing the Product Development Process (PDP). Equally, the engineering design phase of the PDP is undergoing continuous improvements, particularly through advances in Computer-Aided Design (CAD) software tools. Engineering design is considered purposeful when required product functions are realized taking the technical and economic feasibility within a company’s resources into account. To ensure functional fulfillment complementary to CAD, additional Computer-Aided Engineering (CAE) tools have become crucial to generate, simulate and optimize complex designs. Nowadays CAD and CAE tools are well aligned with conventional manufacturing processes (e.g. milling, casting, molding, etc.). However, novel manufacturing technologies, such as Additive Manufacturing (AM), differ in their manufacturing restrictions and thus in the design freedom significantly from conventional manufacturing processes. Therefore, the holistic utilization of AM design potentials, relying on conventional CAD tools and workflows, is impeded.

Originally derived from Rapid Prototyping (RP) technologies, AM is mostly characterized by a layer-by-layer and/or voxel-by-voxel material build-up process that enables previously unavailable degrees of design freedom, such as the realization of components with disregard to casting draft angles, milling tool accessibility, etc., thus allowing purposefully optimized bionic shapes, complex macro- and mesoscopic structures, multi-functional and multi-material designs [1,2,3]. The utilization of these potentials is known to be one main objective of the field of research Design for Additive Manufacturing (DfAM) [1, 4, 5]. As AM reaches technological maturity in many industries, engineers aware of DfAM are increasingly struggling to harness new design potentials dependent on standardized CAD functionalities. For this reason, alternative software solutions are emerging. Those alternative tools address AM related pain points, facilitating the engineering design and optimization of products regarding their topology, geometry, functional architecture as well as manufacturability.

1.1 Research gap and related work

Often, when utilizing AM design freedom during the conception and design phase of the PDP, ambitious geometries with complex topology, shapes and textures result in promising (e.g. performance) improvements. Limited design functionalities and lack of compatibility of CAD and CAE tools, amongst others, impede the purposeful generation of complex geometries [6,7,8,9]. Those limitations also include the nowadays computationally intensive visualization, handling and processing of complex mesoscopic structures subject to, inter alia, the current representation methods CAD systems are based on [10,11,12]. Therefore, CAD tools provided for modeling and generating complex geometries, require further development according to the needs of designers of optimized additively manufactured components [6, 7, 13,14,15]. Thus a complexity shift from the manufacturing phase to the upstream design phase of the PDP, subject to e.g. the omission of manufacturing tools by simultaneously increased geometric and functional part complexity, is perceived.

In the field of research DfAM extensive design and manufacturing process knowledge is analyzed, elaborated, structured and provided through the literature. Here databases and methodologies are suggested in order to enable design engineers to apply AM potentials while considering technology-specific restrictions. In the industrial environment, AM use cases are often simultaneously promoted with development time savings and product performance gains. However, the AM-related complexity shift mentioned above, in particular the engineering design of highly optimized AM parts, is often not pointed out. In this context, shortcomings of engineering design tools and workflow that are necessary to cope with increased AM-related design complexity, have been identified in the state of research. However, the general DfAM process is well understood and has been widely reported in related work [1, 2, 5, 16]. Even though the DfAM process itself is described in the literature with individual consecutive steps, the actual hands-on engineering design workflow in the CAD environment is not yet further described and compared to conventional design workflow [17, 18].

Nowadays several software solutions and environments are necessary to realize optimized geometries taking advantage of AM design freedom. Yang and Zhao categorize them in the following four DfAM relevant software types [18]: Software types in DfAM context:

-

Review and process of 3D-scan-files

-

Solid modelling CAD systems

-

AM process oriented

-

Topology optimization & cellular optimization

The application and combination of those different software environments result in an iterative, complex and unstable workflow for development departments including one-way process steps due to information loss in file conversions. Thus the demand has been raised for a new foundation for CAD systems to overcome limitations enabling an easy-to-use single software solution for those demanding design workflows [7, 13].

Already in 2005 Kasik et al. formulated ten general challenges for CAD systems to overcome, for example, geometry shape control, interoperability across CAD and CAE environments and automatically and meaningfully morphing geometry during design optimization, to name a few [19]. Even though CAD software has improved continuously delivering a variety of design environments and additional functions purposefully developed to alleviate the pain-points of design engineers, those challenges still apply to the context of DfAM today. Thus several not yet addressed AM-specific requirements on CAD/CAE tools can be found in contemporary research addressing different needs of design engineers in the DfAM context [7, 8, 13, 20,21,22].

Besides the DfAM requirements on CAD communicated through research activities in the literature, a survey was conducted by the Technische Universität Braunschweig in the academic as well as the industrial environment with AM users on this topic, amongst others. The survey inquired about habits in CAD systems usage considering the experience level in conventional as well as AM processes of the participants. Additionally, requirements on an ideal CAD workflow suited for DfAM were collected. The overarching objective was to determine which needs are not yet addressed in CAD systems and which functions would be particularly helpful during DfAM. In total, 56 experts predominantly working in technical professions, such as design engineers in an industrial environment, design engineers with AM expertise as well as AM innovation managers participated in this survey. Of all participants, only 28 answered the survey to full extend. For consistency reasons, only those 28 participants were considered for the listings below. The following major findings of the survey emphasize the relevance of the context of this paper:

- 24/28:

-

participants agree that AM knowledge should be implemented in CAD tools supporting design activities on the fly (e.g. design potentials and restrictions based on design rules for efficient and process-specific design)

- 20/28:

-

participants have the opinion that the CAD process must be adapted for the efficient and purposeful application of AM potentials

- 20/28:

-

participants demand useful tools for assisted geometry generation, such as a specification features for purpose designed mesoscopic cellular geometries (e.g. lattice structures), considering limited tools are already available on the market.

The participant’s opinion of why AM is only sporadically present in general product development were spread as follows:

- 22/28:

-

CAD tools do not provide necessary functionality to exploit the AM design potential

- 19/28:

-

manufacturing costs

- 16/28:

-

potentials for cost savings or functional improvements not well understood

- 13/28:

-

certification and quality assurance are unclear

In general, shortcomings in the holistic structuring of DfAM related requirements on CAD have been identified. Further, the consequential development focus points for upcoming CAD tools have not yet been shown. Additionally, necessary design workflow adaptions to cope with increased complexity should be pointed out.

1.2 Objective and approach

The main objective of this work is to address the need for further development in engineering design tools to cope with increasing design complexity in the DfAM context. This is done by gathering and structuring not yet considered DfAM-related requirements on the state-of-the-art CAD tools. Additionally, CAD functionalities of interest, as well as necessary features, are pointed out. Furthermore, necessary adaptions in the engineering design workflow have been identified in this work. By doing so, a contribution to the overall goal, enabling design engineers to holistically utilize AM design potentials, is expected.

To achieve the objective, the following approach is pursued. First, the fundamentals of DfAM and CAD are being clarified as the baseline of this study. Since a structured overview of DfAM needs on CAD tools and CAD basics themselves could not be found in the literature these are therefore elaborated in more detail by the authors. Thus, an introduction to the DfAM topic is given in Sect. 2. Additionally in Sec. 3, the functional structure of CAD systems 3.1 is elaborated, the basics of digital geometry representation is explained 3.2 and a conventional design workflow is displayed 3.3. Afterward, DfAM related requirements on CAD tools are gathered from the literature, complemented and structured in Sect. 4. Then DfAM requirements are interlinked with CAD characteristics in Sect. 5 to indicate relevant focus points for further development in the CAD/CAE context 5.1. Last, necessary consequential design workflow adaptions are derived and envisioned 5.2.

2 Fundamentals of design for additive manufacturing

The field of research Design for Additive Manufacturing (DfAM) refers to methods and tools that influence the methodical design process and serve as support for the identification, application and implementation of AM design potentials while taking AM process-specific restrictions into account [4, 23,24,25,26]. In the DfAM context, one main focus is currently on how to consider AM design potentials and process-specific restrictions during the ideation and conception phases of the general PDP [3,4,5]. To achieve this DfAM suggests several methods and tools intended to assist product development ranging from design rules [27, 28], checklists with references to AM potentials [29], AM-specific knowledge databases [30,31,32,33] or additionally tools such as the systematic network of AM design potentials [23] or the matrix of conflicting AM Potentials [34].

AM is a collective term for many manufacturing processes with differing technological principles (e.g. Powder Bed Fusion (PBF), Selective Laser Sintering (SLS), Binder Jetting (BJ), etc.). Therefore, process-specific manufacturing restrictions must be taken into account to implement AM design potentials purposefully. Specifically, depending on the process of choice, support structures are necessary to buildup overhangs, internal channels and cavities, etc. often prone to tedious removal in post-process. Avoiding specific angles in the design (e.g. by the use of teardrop shapes or by a wisely chosen build orientation) the need for support structures can be mitigated beforehand [2, 3, 32, 33]. Additional restrictions such as layer resolution-dependent surface and contour accuracy, heterogeneous material behavior, etc. are at least equally important but not further explained in detail in this work. However, based on these examples, it becomes clear that process-specific DfAM knowledge positively influences AM part properties as well as pre- and post-processing efforts and should be considered in design tools used in this context [35].

The design freedom of AM processes primarily results from the large number of design features enabled by the layer-by-layer and/or voxel-by-voxel tool-less material buildup process. Those design features can be categorized in following four different types of design complexity as suggested by literature [1]:

Categories of AM related design complexities:

-

Shape complextiy (e.g. bionically distinctive freeform shapes often generated and optimized by algorithms)

-

Hierarchical complexity (macro-, meso- and microscopic structured parts, e.g. lattice structures)

-

Material complexity (multi-material parts with graded material transitions)

-

Functional complexity (aggregation/realization of different functions in one part, e.g. kinematic joints, inserted parts during build, etc.)

The degrees of design freedom summed up in the categories above are mostly inherent to AM and can be considered design levers useful to achieve product-specific or process-specific benefits also known as value propositions. As a result, product benefits such as weight reduction, efficiency gains, reliability improvements as well as process benefits such as decreased assembly costs or shorter time-to-market can be obtained amongst others. [23, 30, 32]

However, as mentioned in the introduction, the implementation of those design potentials depending on conventional CAD tools might turn out challenging. For example, the realization of a bionically distinctive part shape featuring mesoscopic lattice structures [10], near-contour cooling channels and defined surface textures, demand increased CAD modeling effort, a great amount of knowledge and a considerable amount of time.

Figure 1 illustrates the AM process based on Kumke et al. [2, 5, 32]. It becomes clear that the DfAM process is focused on the early phases (I to III) of the AM process. Even though the manufacturing-related phases (IV to VII) need to be kept in mind during the early design stages, they are not further addressed in the scope of this work. According to the general PDP (compare product development process [36]) also the DfAM process chain starts with the I. Planning and task clarification phase, in which the specific engineering task is determined and a list of requirements is derived.

The phase II. Conception follows next. Here the functions necessary to meet the requirements are determined and structured, followed by the development of initial solution ideas and rough concepts. With the support of AM-specific methods, AM design potentials are already considered for problem-solving early in the process. With the completion of phases I and II, the main concept, including functional principles as well as the architecture of the product, is defined.

In phase III. Embodiment and design detailing the computational engineering design and detailing of the 3D part geometries themselves occur. Here the 3D design is realized with the support of CAD tools in the first place. This design phase can be subdivided into embodiment design, setting the overall dimensions and partitions of the product, and design detailing, where the 3D geometries of the product are finalized. Besides CAD tools in general, design engineers often rely on additional support from e.g. simulation and optimization tools (CAE) and AM design rules in order to generate and finalize optimized 3D part geometries in the AM context. This phase ends with the completion of the 3D geometries of parts, assemblies, components and the product itself. As introduced in Sect. 1.1, this phase is the focus of the elaborations in this article.

3 Computer aided design

Starting with the output of 2D engineering drawings in the 1960s, at present one of the main objectives of CAD systems is to define a physical product regarding its 3D geometric shape (from the 1980s on), correct assembly, structure and system components. Therefore, CAD is crucial for engineers to figure out how to produce (Computer Aided Manufacturing, CAM) a complete product and how it might perform once in service (CAE). [19]

To understand the characteristics and limitations of CAD systems, it is necessary to comprehend the basic structure of the system and the design workflow of a design engineer applying it. Therefore, in this section, the basics of CAD structure 3.1 as well as fundamentals on geometry representation of CAD systems 3.2 are summarized. Additionally, the conventional design workflow of design engineers applying CAD tools is further described 3.3.

3.1 Basic structure of CAD systems

CAD systems consist of several elements in order to enable design engineers to visualize, modify, specify, structure and to a certain extent optimize technically feasible geometries in a virtual software environment. For overview purposes those elements have been structured in a new framework with four layers explained in more detail below (Fig. 2). Prior to further insights on the system layers themselves, it is important to mention that the key component of a CAD system, regardless of its scope and functionalities, is still the design engineer [19]. Therefore, the layer descriptions of the system below are described from a design engineer’s perspective. Note that a description from a software developer’s point of view might differ.

3.1.1 Front-end

Front-end elements represent the only touch points between engineer and system, the so-called human-machine-interface (HMI) (Fig. 2outer layer). One major function of the front-end is the visualization of the 3D geometry, enabling an agile interaction often due to a simplified geometry-file format. Besides the geometry visualization, the front-end also displays the geometry manipulation functionalities of the user interface. These depend on the design principle incorporated in the system, enabling the design engineer to create and modify geometries in 3D space (further explained in Sect. 3.3). Additionally, an overview of the product structure is portrayed, often by means of a product tree. The Front-end is therefore the mediator between the design engineer and the software incorporated in the back end.

3.1.2 Back-end

In the back end are all those elements of the software embedded, which are responsible for processing and providing necessary information to accomplish the desired task by the design engineer. It puts the user’s inputs into practice, provides design assistance and enables geometry analysis, amongst others. Nevertheless, the major function of the back-end is the mediation between the front-end and the geometry kernel, processing the information gathered by the frond-end and supported by the embedded geometry kernel accordingly. It tracks the design history and thereby enables the design workflow, defining and generating the desired design output data for manufacturing (Fig. 2second layer).

3.1.3 Geometry Kernel

The main product attribute in the focus of CAD systems is the digital 3D geometry of a technical product. Mainly in charge for the representation of the geometry in the CAD system is the Geometry Kernel (Fig. 2third layer). Here the product’s geometry is mathematically determined in the most accurate and at the same time responsive manner as possible. To achieve this geometry kernels are based on differing mathematical approaches for geometry representation, each of them with its advantages and disadvantages (explained further in Sect. 3.2). The kernel is also capable of processing basic design operations, e.g. boolean operations.

3.1.4 Processing unit

Together all three layers described above work in accordance with each other enabling the entire functionality of the CAD system. All of them are dependent on and are limited by the computer’s or server’s processing unit and its capacities (Fig. 2core).

As the geometry kernel is responsible for the geometry representation it is also a limiting factor in order to enable the design of challenging and optimized geometries. Therefore, further insights into different digital geometry representation approaches are given in the next section.

3.2 Fundamentals of digital geometry representation of CAD systems

An essential part of the virtual development of solid components is the digital representation of their geometric shape. Mathematically, a solid corresponds to a closed subset \(\Omega \) of the Euclidean space \({\mathbb {R}}^3\) in which it lies. Therefore, its digital geometric representation requires a mathematical description that clearly determines which points in space are part of the subset and which are not. Based on [37] and [38], a distinction can be made between two approaches for such a description:

-

Implicit representations use rules to check points for membership of a subset.

-

Explicit representations use rules to create points within a subset.

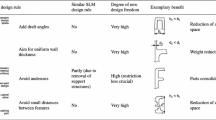

Within these two frameworks, different approaches for digital geometry representations with individual advantages and disadvantages established themselves in the CAD context. For a comprehensive description of common methods, please refer to [37, 39,40,41,42,43]. In the following, the most common methods are summarized and rated in terms of geometric accuracy, computational stability, design freedom, property augmentability and memory efficiency, see Table 1. Property augmentability refers to the possibility of calculating and storing further properties in addition to the pure geometric shape, such as local material properties or the mechanical deformation by using a FEM simulation.

An implicit representation involves the definition of an indicator function that assigns the states true or false to arbitrary input points p, depending on whether that point is inside or outside the subset. Such a function can be obtained by sign-checking an oriented surface distance function. For instance, a sphere of radius r can be defined by the inequality function \({f(p)=|p|^2-r^2 \le 0}\). The geometric shape of solid components usually cannot be defined by a single implicit function. For this purpose, several primitives (spheres, cuboids, cylinders) are combined by Boolean operations (union, intersection, difference). This modeling methodology is also called Constructive Solid Geometry (CSG) [44]. Implicit functions are mathematically exact and numerically efficient. The models are geometrically unambiguous, exhibit simple data structures and low memory requirements. However, the geometric design freedom is comparatively low, making the representation of complex free-form surfaces laborious. Furthermore, implicit functions are less suitable for the simulation and storage of further local component properties.

Another possibility for the definition of an indicator function is the spatial decomposition, also known as spatial occupancy enumeration [45]. Herein, the Euclidean space is discretized by small non-overlapping cells or elements. Usually, uniform cubes (also called voxels) are used for this purpose. By using this method, the indicator function values are not calculated analytically but are stored as a scalar value per cell, either as a signed surface distance function (also referred to as a level set function) or directly as an indicator function (also referred to as a density function). Since these functions are stored as spatially discretized values, no analytical function needs to exist for the geometric shape, leading to high geometric freedom. The spatial decomposition is computationally stable since it is only necessary to ensure that the values per cell are interpretable [46]. Furthermore, the representation can be used to a certain extent for simulation purposes and, for example, individual material densities per element can be stored. An essential disadvantage is the relatively inaccurate description of the surface contour [47]. This can be improved by reducing the cell edge length, although at the cost of a cubic increase in memory requirements. Local refinement methods, such as octree data structures, are often used to alleviate memory capacities [48].

Lastly, for the implicit representation of a solid the so-called Boundary Representation (BRep) can be used. Herein, the volumetric object is described solely by its surface. The corresponding indicator function returns the state true for a point p in space only if this point is enclosed by the surface [37]. Since only the surface is modeled, the memory requirement is comparatively low. However, it must be ensured that the surface is closed and uniquely describes a volume. This may limit the stability of the BRep. Moreover, no additional properties can be modeled inside the component due to the implicit representation of the solid. The surface of a BRep model, in contrast, is usually modeled using an explicit representation, which may lead to high geometric flexibility and accuracy.

In explicit methods, a function is defined which creates points within, and exclusively within the subset of space occupied by the part. For instance, the set of all points on a unit circle can be defined by the parametric function \(f(t)=[\cos (t), \sin (t)]^T\), with \({0 \le t < 2\pi }\). For describing geometrically complex shapes, the object is usually divided into small non-overlapping areas which can be represented by relatively simple functions. The easiest approach for surfaces within a BRep is the division into triangular or quadrangular areas and the use of bilinear parametric functions. The resulting surfaces are polygon meshes containing for instance triangles or quadrilaterals. An essential advantage of polygon meshes is their simple description. There is a wide spectrum of algorithms that have been developed especially for the creation, modification, analysis or visualization of polygon meshes, see e.g. [49,50,51] and [52]. A disadvantage of linear parametric functions is that curved surfaces can only be approximated. Accordingly, a high number of triangles may be needed to fulfill the required accuracy of the representation [43]. In order to be able to accurately represent curved surfaces with few patches, non-linear polynomial functions based on Bézier curves or Non-Uniform Rational B-Splines (NURBS) are usually used in the field of CAD. Depending on the geometric requirements, in addition to a point continuity between the patches, tangent or curvature continuities must also be ensured, which may require a high numerical effort [42]. Nevertheless, due to the superior accuracy, Bézier curves and NURBS represent the industrial standard within CAD [53].

Additionally, so-called subdivision surfaces are used to explicitly represent a surface. The underlying representation is based on a polygon mesh, also called control mesh. For this mesh, schemes are defined according to which it can be refined iteratively. These refinement schemes are designed in such a way that a theoretically infinite number of refinements results in a smooth surface. Depending on the method, a point, tangent, or even curvature continuity can be achieved. The most common refinement schemes are Catmull-Clark [54], Doo-Sabin [55], Loop [56] and Kobbelt [57]. One advantage over NURBS or Bézier curves is that even complex shapes can be represented by a single subdivision surface, eliminating the need to mathematically enforce possibly unstable transition conditions between individual patches. In contrast to NURBS, however, subdivision surfaces can only approximate spheres and cylinders. The resulting error decreases steadily with the use of finer control meshes.

Explicit methods can also be used to directly model volumetric bodies, thus leaving the boundary representation. The extension of bilinear to volumetric trilinear parametric functions form a composite of polyhedra, e.g. tetrahedra or hexahedra, which geometrically represent the solid. Likewise, non-linear parametric functions such as splines and subdivision schemes are extendable to volumes. But due to the complex parameterization, these are barely used (exception in [58]). The pure explicit representation of solids is well suited for the simulation of component properties, for which tetrahedra and hexahedra in particular represent the industrial standard for FEM simulations.

For solids, usually, an implicit representation with spline surfaces (BRep) is used in the field of CAD and an explicit representation with polyhedra is used in the field of CAE. The most common methods and their properties are summarized in Table 1. It should be noted that this is intended to provide general orientation and does not claim to be exhaustive. For a more comprehensive evaluation of digital representation methods for different application purposes, please refer to [59].

3.3 CAD design workflow and design principles

The focus of this section is set on the design engineer’s workflow itself, as he/she is also identified as a major limiting factor for the realization of highly optimized complex geometries.

The design workflow of a design engineer is often highly specialized to the context and application and particularly the chosen manufacturing process of the physical product (e.g. sheet metal, casting, ...). Nevertheless, some patterns can be abstracted from engineering design workflows that apply to a majority of design tasks. According to design methodology, design tasks in industrial context can be classified into three main categories: original, adaptive and variant design [36]. Even though in most industrial cases design variations (70%) and design adaptations (15%) occur, the majority of methods suggested in the field of research design methodology address original design tasks [60]. Considering that the research field DfAM strongly emphasizes the importance of implementing AM design potentials at the early conception phase, in order to utilize them holistically (see Sect. 4), the present study also focuses primarily on the design workflow for original designs. The upcoming description of an exemplary conventional design workflow is based on, for technical applications widely established, parametric, associative as well as history- and feature-based modeling tools only (further information see [61]).

Before describing the conventional design workflow in detail, it is important to clarify the underlying understanding of the hierarchy of the product architecture of complex products. The product hierarchy is often set as follows. A product is composed of several components that are compiled from different assemblies again consisting of different parts (e.g. automotive vehicles). Nevertheless, for simplicity reasons in this work the two levels component and assembly are considered as one (Fig. 3center).

The conventional design workflow illustrated in Fig. 3(left) is structured into five main steps and starts after the product planning phase is concluded (compare product development process PDP [36]). This means that the specifications, the functional scope as well as the basic concept decisions should already be completed before the detailed engineering design work in the CAD environment begins.

In the \(1{\mathrm{st}}\) step of the design work, the product requirements, such as the, overall dimensional measures and values to be met documented in the specification sheet, need to be translated into the design space. This includes, for example, the virtual location/orientation of the product, main package dimensions, assembly structure and part count as well as specific non-design areas due to technical principles, regulations, ergonomics, etc. all together, a part of the embodiment design. The deliverables from this phase are a so-called 3D package model and sometimes even freehand pre-sketches illustrating the first steps of the approach for the following detail design.

A product architecture often consists of structural components carrying subcomponents which in turn are built from assemblies comprising from different parts. Therefore, the detailed design phase in the following \(2{\mathrm{nd}}\) and \(3{\mathrm{rd}}\) step of the illustrated workflow in Fig. 3(left) often occurs on the part level of the product structure. Quite typical for conventional parametric associative modeling tools is to create necessary 2D reference geometries in the \(2{\mathrm{nd}}\) step of the workflow in Fig. 3(left). Those might be for example planes and sketches (incl. points, lines, axles), often parametrically defined, describing basic profiles, topology and shapes on which the 3D geometries are associatively built upon later on. Subsequent changes in those associated geometries and parameters influence the downstream design history significantly.

Based on the 2D digital reference geometries the 3D part is modeled in the \(3{\mathrm{rd}}\) step of the workflow. This step is nowadays mostly enabled by features both in surface and volumetric modeling environments. Additionally, inter-volumetric operations, also known as boolean operations can be applied to shape at least two independent closed volumes based on their intersections. Through iteration of the steps 2 and 3 in the workflow the detailed part design is elaborated. Further, the interfaces to neighboring parts of the same assembly need to be taken into account. Results from this phase are the native 3D VRep/BRep-based design data of the design drafts of the parts/assemblies including their design history and constraints amongst each other.

The \(4^{\mathrm{th}}\) step usually belongs to the context of CAE and addresses the virtual simulation and optimization of the suggested geometry in order to estimate its performance in service [19]. In the last two decades, the relevance of this step increased significantly due to its gained validity and development costs saving potential minimizing testing efforts, material usage and part failures in use. Therefore, and due to its iterative character, CAE solutions are more and more merging with CAD software environments.

After the design drafts from the \(3{\mathrm{rd}}\) step have been validated and optimized through simulation and optimization, the design finalization and the data export for manufacturing (CAM) as well as the design documentation are conducted in the \(5{\mathrm{th}}\) step of the workflow (Fig. 3left). Thereby the first design release is accomplished and the component proceeds in the development process with e.g. prototyping, testing, etc. Additional design iterations are not unlikely as not all product performance aspects can be validated virtually beforehand yet. This workflow describes only the main stages of a generalized design task in CAD and does not claim to be holistically applicable to each specific context.

To accomplish the modeling act by the design engineer described in the \(2{\mathrm{nd}}\) and \(3{\mathrm{rd}}\) step (see Fig. 3left) three different established principles for geometry manipulation can be distinguished to date. Each of them has advantages and disadvantages and should be chosen wisely by the design engineer at the beginning of detail design (see Fig. 3step 2 left).

-

Script-based modeling Generating and manipulating virtual geometries in a coded manner. The coded script describes the subsequent geometrical operations and is compiled and represented by the CAD geometry kernel. Nowadays rarely used by design engineers. Particularly suitable for programming geometry generators that, once set up, create design variants based on varying input parameters automatically.

-

Direct modeling Generating and manipulating virtual geometries by mouse/touch-pad/touch-displays gestures (click, drag, pinch, etc.) directly visually affecting changes in the geometry in the desired fashion. Up today still strongly implemented principle in mainstream CAD systems.

-

Feature-based modeling Generating and manipulating virtual geometries by means of preprogrammed features that enable to specify and implement a variety of design elements (e.g. extrusions, pockets, rotations, offsets, chamfers, etc.). This design principle has a substantial share in the functional scope of mainstream CAD systems and is often embedded supplementary to direct modeling capabilities of the software.

Those design principles demand specialized skills and often lead to intensive manual labor attempting to design highly optimized complex geometries.

4 Design for additive manufacturing requirements on computer-aided design

AS CAD tools have evolved hand in hand with conventional manufacturing processes over the past few decades, in particular design features related to conventional manufacturing processes were developed. Consequently, important functions for the design of high complexity AM parts have not yet been realized, or are only implemented in a rudimentary manner.

As a result of this demand, several alternative software tools and plugins emerged on the software landscape offering supplementary functional scope compared to conventional and established systems. Table 2 displays an exemplary software overview accordingly. On the left side software examples of industry-standard solutions are mentioned either with a focus on technical (CAD/CAE) or stylish (3D modeling) designs (see Table 2left). This differentiation is important to consider, since many 3D modeling software solutions are not suitable for accurate technical engineering design (e.g. not accurate enough, no design history, no associativity, etc.). Nevertheless, emerging specific functions and plugins turn out to be helpful in the DfAM context.

On the right-hand side, alternative software solutions are mentioned that emerged offering additional benefits to engineering design in the DfAM context. Those examples have either been alienated from other neighboring design sectors to mechanical engineering (market pull), for instance architectural design, or have been purposely developed for and promoted in the DfAM community (technological push). To name a few, the additional benefits enabled by those alternative tools range from increased stability and agility of complex geometries, graded material density or voxel-based generative design functions up to enhanced processing performance (Table 2exemplary feature).

However, the needs of designers in the DfAM context do not just become clear in their migration to alternative software tools but also through research communicated in the literature in this field. By gathering those needs in related work and complementing them with additional requirements, six categories relevant to the design workflow can be distinguished (Fig. 4). Some requirements address shortcomings in the overarching design-workflow and product structure itself. The remaining five categories point out specific requirements: for example necessary functionalities in material and geometry representation in the CAD system. Also, requirements regarding the geometry manipulation by the design engineer are in focus here. Additional requirements addressing the CAE context for instance simulation as well as geometry optimization/generation are addressed as these steps are crucial to achieve highly optimized but feasible designs and thus are closely related to DfAM. In the following paragraphs, exemplary needs and requirements from each of those major categories are mentioned according to Fig. 4.

4.1 Design-workflow & product structure

General shortcomings towards the number of different software environments necessary for DfAM and the missing cross-cutting parametrization [8], the resulting highly iterative workflow [17] as well as the limited compatibility of CAD and CAE environments [6, 8, 19] are pointed out in the literature. Also, the overall need for additional computation performance is expressed [14] accordingly (Fig. 4). Additionally, there are specific needs towards stable and agile parameterized complex geometries keeping design history and enabling the generation of design variants. Here visual scripting software such as e.g. Grasshopper, xGenerative Design, Dynamo Studio, etc. is being used for the design of geometry generators that enable engineers to put the individualization potentials of AM into practice realizing applications like customized products with lot size one (Table 2). Furthermore, dynamic assembly design features would be helpful to support functional integration and part consolidation potentials of AM (Fig. 4). At this point, a function centered additionally to the part-centered product structure would be crucial. In addition, the possibility to set restrictions regarding AM manufacturing processes on the assembly level, to carry out AM design studies as well as implemented knowledge databases with DfAM content should also be considered in the future [62].

4.2 Material representation

Most needs expressed in this category are derived from the capability of several AM processes to influence material properties as well as interchange materials [1, 4] in voxel-based fashion [3, 14, 63]. First of all the possibility to vary material properties, for example, a graded density/porosity inside one part geometry would enable the design engineer to tune the material’s performance of the part to differing local requirements. This should be made possible on different hierarchical levels, for example, micro- (e.g. grain structure of metals [59]), meso- (e.g. cellular structures like lattices and honeycombs [11, 12, 59, 63]) and macroscopic (e.g. differing transitioning materials in certain areas of the part [20]) level. Nowadays this is often carried out by designing matched yet stand-alone part geometries, that get assigned to different materials prior to the printing process. However, gradients/transitions in material properties and kind are not yet feasible with manageable effort following this workaround. Also, heterogeneous material properties due to the manufacturing process (e.g. tensile strength weakness perpendicular to layer) should be considered in the CAD/CAE environment.

4.3 Geometry representation

Regarding the geometry representation in CAD environments additional needs result from challenges in the transformation of optimization results (often triangulated/tessellated hollow surfaces e.g. STL) into editable CAD data (e.g. VReps or closed BReps) [11, 22] (Fig. 4). Furthermore functions like advanced offset operations to hollow out volumes [22], substitute surfaces with topology constrained patterns [59] as well as the materialization of geometries [59] are also strongly dependent on the kind of geometry representation (e.g. VRep or BRep). Considering that each kind of geometry representation in the CAD environment is more suitable for certain applications than for others, more flexibility in the interchangeability of the representation approaches is necessary. The Dyndrite software is one example that addresses this need considering the right geometry representation type for the right task (Table 2).

4.4 Geometry manipulation (design principle)

Apart from general design challenges, for example, the high number of involved software tools and the iterative character of the DfAM processes, the literature does not mention many needs addressing the hands-on engineering design workflow itself. Considering that in the AM context, the development process, in particular managing design and simulation complexity, turns out to be one major bottleneck rather than the production complexity itself, new design features and design principles are necessary to utilize AM design potentials further. Additional design features for example assisted duct and channel design, irregular patterns on free-form surfaces and surface texturing tools would already simplify design problems significantly (Fig. 4). Besides additional features, in conventional CAD environments certain complications in engineering design cannot be handled reasonably with direct modeling techniques. Due to the tool-less character of AM technologies design variations/improvements/adaptions are not as devastating as for tool-based manufacturing techniques, leading to additional potentials towards individualized consumer products as well as open-loop development. Therefore, a new level of parametrization is required. To be able to generate and alternate designs with a feasible amount of effort, CAD data should be understood less as a virtual adaptive 3D model targeting design freeze but rather be comprehended as parametric geometry generators, which based on changing input parameters deliver updated geometries on the basis of the same underlying basic concept over and over again. For this purpose, additional design principles such as visual scripting environments should be implemented in conventional CAD tools, allowing design engineers to program their geometries with ease in the future.

4.5 Performance simulation (CAE)

One major challenge that design engineers confront during performance simulation of complex geometries is the processing capabilities of the CAE systems [52, 59]. Bermano et al. as well as Vaissier et al. indicate that approximations & reductions are often necessary in order to achieve tessellated models that are computable with a reasonable amount of resources. Those simplifications might result in distrust in the significance of simulation results and subsequently in the performance of the part in real use. Due to functional integration and part consolidation potentials of AM technologies, parts optimized for AM often cover an increased functional scope in comparison to conventional designs. These circumstances lead to increased functional complexity that need to be modeled in future simulation environments [13, 64].

4.6 Geometry generation & optimization

As AM manufacturing capabilities exceed human modeling capabilities, algorithmic geometry generation (including topology optimization) is frequently applied in the DfAM context. Shortcomings in current optimization software solutions either point to missing functionalities or suggest improvement of already existing ones (Fig. 4). Addressing topology optimization itself, the integration of manufacturability and post-process restrictions, a VRep output of the resulting blueprint geometry ready for detailing as well as optimization functionalities on voxel-level are pointed out as development tendencies for the future by the literature, amongst others [59]. Furthermore, the AM independent need for topology optimization to be able to consider non-linear plastic material behavior is crucial for the implementation of the method for design problems towards energy dissipation (such as crash-relevant structural vehicle parts). Additional functionalities mentioned and desired by the field of research are path optimization tools for integrated fibers and ducts, enhanced structural patterning and hollowing techniques as well as automated stiffening of complex surfaces [22, 59]. Moreover, the generation of purposeful mesoscopic structures (e.g. load oriented structural lattices [65]), distance and routing optimization of component-internal ducts (e.g. close to the freeform surface) as well as multi-physics optimization capabilities are also improvement areas for upcoming optimization tools.

5 Proposed improvements in engineering design tools and workflow

Based on the needs of the DfAM field of research on CAD/CAE environments introduced in Sect. 4, necessary development tendencies for upcoming CAD tools and adaptions to the design workflow can be pointed out. Both of these are explained in more detail in the subsections below.

5.1 Focus points for further CAD development

As described in Sect. 3.1, Fig. 2 does not only display today’s CAD structure and characteristics but also suggests relevant CAD characteristics as focus points for further development. In the following paragraphs, those CAD-specific focus points are summarized according to the corresponding category.

5.1.1 Geometry representation

As introduced in Sect. 3.2, several different mathematical boundary-based or volume-based approaches can be considered to describe a geometry (Fig. 2), each of them presenting their own advantages and disadvantages (Table 1). CAD systems nowadays only support certain representation approaches, often leading to dead-ends and conversion efforts further down the line. However, none of those approaches can be indicated as the single most suited approach to enable complex AM designs in the future. Nevertheless, a major deficit in DfAM is the missing capability to represent heterogeneous material distributions as well as micro-, meso- and macroscopic non-uniform structures inside a single part, that in combination with CAE functionalities are purposely designed to a specific use-case [63]. Such functionalities would unleash new complexity levels to exploit AM design potentials further. Therefore, development efforts should focus on the capabilities of upcoming CAD systems to support, convert and combine implicit as well as explicit representation methods using the right approach for the right design task. In the best case, this should occur seamlessly in the back end of the system, as this mathematical level is not in the focus of design engineer’s expertise. Please note that the mathematical feasibility of such functionalities cannot be properly estimated by the authors, nevertheless alternative software tools are already implementing similar functionalities to such extent (see example Dyndrite in Table 2).

5.1.2 Geometry manipulation

Up to today design engineers themselves as humans are the central and fundamental element of the design process [36]. This constellation also applies to future design applications, even though in the DfAM context, the human might turn out to be the limiting factor in the pursuit of optimized designs. If the geometry manipulation functionalities of CAD tools are not effortless enough, design simplifications as short-cuts to reduce modeling efforts occur, result in part performance losses. Therefore, it is crucial that design tools in use facilitate complex design tasks further. For this reason, the category geometry manipulation focuses on different manners of how design engineers are enabled to model virtual designs via the systems front end (Fig. 2). At present, most CAD solutions are based on a combination of the design principles direct and feature-based interaction of the designer with the virtual geometry, as introduced in Sect. 3.3. Depending on the design task these design principles turn out to be labor intensive and, consequently, inefficient to achieve complex geometries [9]. Additional design principles, for example visual scripting,—are emerging amongst complex and variant-driven designs. Visual scripting enables the design engineers to program associative parametric geometries using functional building blocks that get interlinked with in- and output parameters in a logical fashion. Those by this means compiled functional diagrams can be considered as geometry generators, in which parameter adjustments lead to new design variants in an agile, stable and manageable manner. This design principle is a key feature of emerging software solutions (see Grasshopper, Dynamo Studio, xGenerative Design in Table 2) and is highly considered in the realization of specification tools for individualized products. Due to the limitation of humans to determine highly optimized geometries and the intensive labor necessary to directly designing them, algorithmic geometry generation plays an increasingly important role in the DfAM context (e.g. topology optimization, generation of mesoscopic structures, etc.). As mentioned in Fig. 2set boundary conditions is the crucial step for algorithms to generate purposeful geometries within a characterized design space. The action of setting correct boundary conditions for specific use cases is an engineering task that cannot be easily conducted by generative design tools themselves and thus will increasingly be part of a design engineer’s workflow. Consequently, set boundary conditions can be considered as an additional design principle and should be a focus in geometry manipulation functionalities of upcoming CAD systems. This relation emphasizes the ongoing aggregation of CAD and CAE tools. Similar to the different geometry representation approaches mentioned above, each design principle has its right to exist and is advantageous for a specific design task. Therefore, the seamless combination of those design principles should also be addressed in the development of future design tools (see e.g. xGenerative Design in Table 2).

5.1.3 Product structure

Assemblies and entire products consisting of numerous parts can be designed using contemporary CAD tools. Conventionally, the product structuring approach implemented in the CAD environment is based on part-assembly-affiliations and resembles the assembling order of the product to a certain extent. Rightfully so, thus conventional complex products often consisted of numerous manufacturable parts so far. However, an assembly structure does not necessarily equal the function structure of a product [36]. Particularly in the DfAM context where part consolidation and functional integration are considered AM design potentials [23], the assembly and function structure of a product might differ intensively. This often leads to part count reduction and thus decreased assembling complexity of the product. Nevertheless increased function complexity on part level results. Even though more functionally complex and merged parts can be manufactured with AM technologies, component boundaries need to be chosen wisely and shift iteratively during the design process. Additionally, specific functions need to be interlinked to geometrical features/segments of complex parts to enable localized material properties, functional fulfillment analysis, geometrical optimization and design space shortages of and in between features on the part. Consequently, additionally to part oriented, also function oriented product structures should be implemented in future CAD systems enabling functional localization in the design space and part geometry as well as dynamic assembly design functionalities such as alterable part boundaries as well as advanced boolean operations.

Building upon those potential advancements for upcoming CAD developments mentioned above, design engineers might be able to overcome design challenges with increased complexity more efficiently in the future. However, to exploit AM design potentials fully, it is not only necessary that CAD/CAE environments are further developed but also the design workflow of design engineers itself might need to be adapted.

5.2 Suggested prospective design workflow to consider DfAM related needs

The following descriptions refer to the envisioned design workflow illustrated in Fig. 3 (right) and can be compared with the exemplary conventional design workflow Fig. 3 (left). The first major difference between contemporary and envisioned design workflow identified is the increased emphasis on the component level of the process. The detailed part design is only approached after a sensitivity analysis of the design space and a rough embodiment design phase, both of which are conducted still on component level (for further details see the specific step descriptions below). The second differentiation is the emphasis on the functional composition of the component before the geometric design itself. The main structure of the envisioned workflow of Fig. 3 is based on the following three premises:

-

\(1 {st}\) Premise Due to AM design freedom (e.g. functional integration and part consolidation potentials), AM components are prone to reach higher levels of functional complexity in comparison to conventional manufacturing processes.

-

\(2 {nd}\) Premise With increased amount of functions to be realized in one component, a higher probability of design space disputations in between those functions can be expected.

-

\(3 {rd}\) Premise In comparison to conventional manufacturing technologies, AM is often considered to manufacture computer generated optimized geometries that exceed human design capabilities, leading to increasing utilization of generative algorithm-based design principles in the DfAM context (e.g. topology optimization, generation of mesoscopic structures, etc.)

Based on the assumptions above, the upcoming design workflow could enable increased shape, hierarchy and material as well as function-related complexity and support the management of design space disputations in between functions. If the set of functions, to be implemented in the component of choice, is assignable to more than one technical faculty (e.g. Mechanics, Thermodynamics, etc.) the term multi-physics design is considered appropriate for this particular design task, which refers to new design opportunities and complications. The following additions or differentiations to the conventional design workflow are envisioned as necessary to manage the increased design complexity mentioned above:

Step 1–Transfer of requirements into virtual 3D space: Besides the requirement transfer a more detailed design space characterization already in the first step of the workflow might be necessary, setting the foundation for the following sensitivity analysis of the design space. A detailed design space characterization includes for example boundary conditions of all kinds, definitions of safety-critical zones, negotiable and non-negotiable design limitations as well as interface specifications if already determined. This means that subsequent to the first step the design engineer does not proceed with manually designing auxiliary geometries (mostly in 2D) necessary for the 3D part design (Fig. 3left step 2). Instead, based on the characterized design space, the set of boundary conditions and the necessary CAE functionalities, the design engineer conducts a sensitivity analysis (step 2.A) of the design space.

Step 2A–Sensitivity Analysis: The main objective here is to determine the most relevant segment of the available design space to realize each function of the component to its optimum (e.g. functions similar to load, fluid, heat transfer, etc.). Nowadays this step is done mostly based on the cognitive experience and intuition of design engineers, which might be insufficient for design tasks with increased function and geometric complexity. The sensitivity analysis envisioned here relies on early-stage simulation functionalities of future CAD/CAE systems addressing each technical faculty relevant for the components functional fulfillment (e.g. Mechanics, Fluid-, Thermo-Dynamics, etc.). For example, sensitivity analysis as such are already common in the context of Computational Fluid Dynamics (CFD) and performed in the early stage of CFD simulations to determine the area of highest relevance for a targeted value (e.g. area of highest flow rate or lowest pressure losses in the perfused volume). The computed results can be provided as enveloping surfaces in the 3D design space. Those results should by no means be considered as design geometries ready for detailing. In fact, those envelopes only indicate design space segments of high importance for the fulfillment of a particular function, in this example a function based on fluid transfer. Once a sensitivity analysis has been conducted for each function to be realized in the same design space of the chosen component, those individually computed results should be superposed. This way areas of cross-functional conflicts in the design space of interest are revealed. Step 2B–3D Monolythic Embodyment Design: Based on the 3D sensitivity map with identified zones of conflict in the design space of the previous step 2A, the step 2B strives towards an optimal compromise amongst the respective design space disputations. This step is still conducted on component-level and is understood as the transition to the part-level of the design workflow. To maximize the exploitation of the functional integration potential of AM, this step should be conducted from a monolithic perspective as a starting point. Therefore, the focus is on the embodiment of the entire component. To do so the component should be designed as a one-piece design in the first place (comp. one-piece-machine strategy [60]), with e.g. a material presence according to load transfer intersections or material absence according to fluid/medium transfer intersections. Direct and feature-based design principles might be chosen to do so (e.g. a wrapping of the envelope surfaces of the sensitivity map to start with). Based on the 3D sensitivity map as blueprint, sub-concepts might be necessary to solve the beforehand identified zones of conflict in the respective design space. Conventionally those zones of conflict don’t even occur due to disciplinary instead of interdisciplinary design approaches or are defused by prioritization/de-prioritization of the respective functions (e.g. load-transfer surpasses aerodynamic performance). Considering AM design potentials a de-prioritization of a function might not be necessary. Varying material properties, geometric design freedom and material transitions in the same part are a few examples of design measures that enable the engineer to find compromises for design space disputations renouncing sweeping function prioritization. Subsequently, the partitioning of the component into individual parts need to be considered (e.g. due to necessary relative movement in-between parts, replacement of wear parts, etc.). The necessary part transitions should be set wisely, taking appropriate AM process-specific restrictions into account. Depending on the geometric complexity level or the parametrical extent of the design task, a suitable design principle should be chosen for each part as preparation for design detailing (Fig. 3step 2B).

Step 3–3D Part Design: On the part level of the product structure, the detailed 3D part design is elaborated. This step focuses on a particular partition of the previous monolithic embodiment and should be repeated for each partition of the blueprint. The partitions set and the sub-concepts developed by the design engineer previously can also be considered as a new design space definition and boundary conditions on the part level if a generative design principle is chosen to further determine the optimal geometry of the part. This workflow presupposes that CAE functionalities (e.g. topology optimization) are seamlessly integrated and provide native CAD data as design results to be detailed. Independently of the design principle of choice (direct, feature-based, scripted, visually scripted or generated), due to the sensitivity analysis and the embodiment design as a blueprint, design engineers do not necessarily rely on the 2D design of auxiliary geometry as a starting point for their part design anymore. In the best case, a seamless transition in between different design principles is enabled by the CAD system, allowing design engineers to switch to the most appropriate design principle for each particular task. Additionally, functionalities towards the parametric design of intersections (e.g. flanges, mounting points, welding seams, etc.) should be implemented in the feature set in a parametric manner. Due to the global character of the previously set component partitions, changes in those partitions on the component level should automatically lead to adaptions of the part level design history, enabling this way agile design adaptions and minimizing part collisions on the component level.

According to the descriptions in Sect. 3.3 the envisioned design workflow continues with an iterative performance validation of the designed parts and components in step 4 by simulation and optimization functionalities closely related to the conventional approach. The design workflow is finalized with the export of production files and documentation data in step 5.

6 Discussion

With this work, it becomes clear, that even though the field of research DfAM is broadly investigated, the hands-on design process still conceals challenges that are not yet fully addressed. In general, the needed improvements in CAD tools expressed in this work are not only beneficial for the DfAM context only. Also established manufacturing processes, such as, amongst others, die-casting, also enable high degrees of freedom in design and might profit from additional CAD functionalities towards functional integration as well as the facilitated design of complex geometries. Even though the engineering design workflow envisioned has been derived from a DfAM background, several aspects emphasized in this paper, such as interdisciplinarity and complexity management in design, also apply to engineering design processes in general.

Limitations of this work are on the one hand the validation of the envisioned design workflow. Due to dependencies on available CAD tool functionalities, a detailed validation is yet impeded. On the other hand, partial steps, for example, sensitivity analysis, are not defined in detail for specific engineering faculties beyond Mechanics and Fluid-Dynamics. It is also important to point out that generative design principles are gaining relevance in general and are not applied only in AM context. The design workflow comparison illustrated in this contribution (Fig. 3) is based on a rather traditional approach in order to clarify principles in sufficient contrast, thus not supposing that design tasks for established manufacturing processes are all conducted in a traditional and straightforward fashion. Additionally, this work is aimed towards rather complex design tasks in the DfAM context, not assuming that all AM applications require a high level of design complexity to be purposeful. Furthermore, AM-process-specific restrictions (e.g. dependency on support structures) vary significantly in between differing technologies which might lead to severe limitations in design freedom for particular processes. Additionally, it should be considered that the maximization of part consolidation and functional integration impacts product maintenance possibilities further down the line in the product life cycle, for example, ease and cost of part replacement.

Implications for future research with a focus on CAD systems consist of further investigations of back-end related consequences and measures necessary to realize DfAM the requirements pointed out in this work. With regard to the CAE functionalities, crucial for the feasibility of this introduced design workflow, further detailed research on the definition of sensitivity analysis of design space for each technical discipline is necessary. This way multi-physics applications would be facilitated. With a focus on the software landscape, a detailed analysis of DfAM requirements, not yet addressed by alternative software solutions, would provide further insights on development white spots for software developers. An additional area to be further analyzed in the context of product development are useful methods to manage requirement complexity and trade-offs. Also, the comparison of increased product reliability by minimizing points of weakness in design (e.g. intersections) as opposed to impeded ease and increased cost of part replacement due to part consolidation and functional integration should be analyzed in more detail.

7 Conclusion

The main objective of this work was to address the need for further development in engineering design tools (CAD/CAE) to cope with increasing design complexity and thereby enable design engineers to utilize AM design potentials in the mid-term future. To do so a four-step approach was conducted. First, comprehend the fundamentals of DfAM and CAD. Second, gather and structure DfAM related requirements on CAD tools. Third, interlink DfAM requirements with CAD characteristics to reveal relevant focus points of improvement. Fourth, derive the consequences to the respective design workflow accordingly. The major outcomes of this work are an overview of the CAD characteristics from a design engineer’s perspective (Fig. 2, Table 1) and a structured collection of DfAM related requirements on CAD (Fig. 4). Further potential adaptions to the conventional engineering design workflow are illustrated and suggested as a draft process diagram (Fig. 3).

A general finding of this work is that numerous not yet addressed requirements of DfAM on CAD exist (Fig. 4). Furthermore, it has been shown that to address those needs the development of additional CAD features is not sufficient. All four main layers of CAD systems (front-end, back-end, kernel & processing unit) might require further development and increased versatility (Fig. 2). However, it has been shown that not only CAD tools themselves might need to adapt towards function-oriented design and enable interdisciplinarity but also the design engineer’s workflow itself should evolve to cope with additional complexity and utilize AM design potentials to full extend.

In conclusion, a contribution towards the convergence of methodological DfAM and CAD development is provided within this work enabling a scientific discourse with the potential to further improve engineering methods and tools.

References

Ian, G., et al.: Additive Manufacturing Technologies. 3rd Edition. Springer Nature Switzerland AG (2021). https://doi.org/10.1007/978-3-030-56127-7

Gebhardt, A., Hötter, J.-S.: Additive manufacturing: 3D printing for prototyping and manufacturing. Munich, Hanser Publishers, and Cincinnati: Hanser Publications (2016)

Kumke, M.: Methodisches Konstruieren von additiv gefertigten Bauteilen: dissertation. Wiesbaden: Springer Fachmedien Wiesbaden, (2018). https://doi.org/10.1007/978-3-658-22209-3

Thompson, M.K., et al.: Design for additive manufacturing: trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 65(2), 737–760 (2016). https://doi.org/10.1016/j.cirp.2016.05.004

Kumke, M., Watschke, H., Vietor, T.: A new methodological framework for design for additive manufacturing. Virtual Phys. Prototyp. 11(1), 3–19 (2016). https://doi.org/10.1080/17452759.2016.1139377

Abele, E., Reinhart, G.: Zukunft der Produktion: Herausforderungen, Forschungsfelder, Chancen. Hanser (2011)

Beyer, C.: Strategic implications of current trends in additive manufacturing. J. Manuf. Sci. Eng. (2014). https://doi.org/10.1115/1.4028599

Dalpadulo, E., Pini, F., Leali, F.: Integrated CAD platform approach for design for additive manufacturing of high performance automotive components. Int. J. Interact. Des. Manuf. (IJIDeM) (2020)

Dalpadulo, E., Pini, Fabio, Leali, F.: Assessment of computer-aided design tools for topology optimization of additively manufactured automotive components. Appl. Sci. (2021). https://doi.org/10.3390/app112210980

Azman, A.H., Vignat, F., Villeneuve, F.: CAD tools and file format performance evaluation in designing lattice structure for additive manufacturing. Jurnal Teknologi (2018). https://doi.org/10.11113/jt.v80.12058

Nguyen, D.S.: Design of lattice structure for additive manufacturing in CAD environment. J. Adv. Mech. Des. Syst. Manuf. (2019). https://doi.org/10.1299/jamdsm.2019jamdsm0057

Nguyen, C.H.P., et al.: Implicit-based computer-aided design for additively manufactured functionally graded cellular structures. J. Comput. Des. Eng. 8(3), 813–823 (2021). https://doi.org/10.1093/jcde/qwab016

Bourell, D., Rosen, D.: Roadmap for additive manufacturing - identifying the future of freeform processing. Tech. rep. The University of Texas at Austin (2009)

Gao, W., et al.: The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 69, 65–89 (2015). https://doi.org/10.1016/j.cad.2015.04.001

Zhang, B., et al.: CAD-based design and preprocessing tools for additive manufacturing. J. Manuf. Syst. 52, 227–241 (2019). https://doi.org/10.1016/j.jmsy.2019.03.005

Belkadi, F., et al.: Towards an unified additive manufacturing product-process model for digital chain management purpose. In: 28th CIRP design conference. Vol. 70. 28th CIRP design conference 2018, 23-25 May 2018, Nantes, France. pp. 428–433 (2018). https://doi.org/10.1016/j.procir.2018.03.146

Briard, T., Segonds, F., Zamariola, N.: G-DfAM: a methodological proposal of generative design for additive manufacturing in the automotive industry. Int. J. Interact. Des. Manuf. (IJIDeM) 14(3), 875–886 (2020)

Yang, S., Zhao, Y.F.: Additive manufacturing-enabled design theory and methodology: a critical review. The Int. J. Adv. Manuf. Technol. 80(1), 327–342 (2015)

Kasik, D.J., Buxton, W., Ferguson, D.R.: Ten CAD challenges. IEEE Comput. Graph. Appl. 25(2), 81–92 (2005). https://doi.org/10.1109/MCG.2005.48

Grigolato, L., et al.: Heterogeneous objects representation for additive manufacturing: a review. Instant J. Mech. Eng. (2019). https://doi.org/10.36811/ijme.2019.110002

Dalpadulo, E., Pini, F., Leali, F.: Assessment of Design for Additive Manufacturing Based on CAD Platforms. In: Rizzi, C., et al. (eds.) Design Tools and Methods in Industrial Engineering, pp. 970–981. Springer International Publishing, Cham (2020)

Bernhard, M., Hansmeyer, M., Dillenburger, B.: Volumetric modelling for 3D printed architecture. Adv. Architect. Geom. 392–415 (2018)

Kumke, M., et al.: Methods and tools for identifying and leveraging additive manufacturing design potentials. Int. J. Interact. Des. Manuf. 12(2), 481–493 (2017). https://doi.org/10.1007/s12008-017-0399-7

Ponche, R., et al.: A novel methodology of design for additive manufacturing applied to additive laser manufacturing process. Robot. Comput.-Integr. Manuf. 30(4), 389–398 (2014). https://doi.org/10.1016/j.rcim.2013.12.001

Doubrovski, Z., Verlinden, J. C., Geraedts, J. M. P.: Optimal design for additive manufacturing: opportunities and challenges. In: vol. Volume 9: 23rd international conference on design theory and methodology; 16th design for manufacturing and the life cycle conference. International design engineering technical conferences and computers and information in engineering conference. pp. 635–646 (Aug. 2011). https://doi.org/10.1115/DETC2011-48131

Adam, G.A.O., Zimmer, D.: Design for additive manufacturing-element transitions and aggregated structures. CIRP J. Manuf. Sci. Technol. 7(1), 20–28 (2014). https://doi.org/10.1016/j.cirpj.2013.10.001

Mani, M., Witherell, P., Jee, H.: Design Rules for additive manufacturing: a categorization. In: Volume 1: 37th computers and information in engineering conference. American Society of Mechanical Engineers, 8062017. https://doi.org/10.1115/DETC2017-68446

Adam, G.A.O.: Systematische Erarbeitung von Konstruktionsregeln für die additiven Fertigungsverfahren Lasersintern, Laserschmelzen und Fused Deposition Modeling. Dissertation (2015)

Wegner, A., Witt, G.: Konstruktionsregeln für das Laser-Sintern. Zeitschrift Kunststofftechnik (WAK) 2012(3), 252–277 (2012)

Maidin, S.B., Campbell, I., Pei, E.: Development of a design feature database to support design for additive manufacturing. Assem. Autom. 32(3), 235–244 (2012). https://doi.org/10.1108/01445151211244375

Weiss, F., Binz, H., Roth, D.: Approach to consider Rapid Manufacturing in the early phases of product development. In: Weber, C. (Ed.), Design for life. Vol. 4. DS / Design Society. Glasgow: Design Society, pp. 1–10 (2015)

Watschke, H.: Methodisches Konstruieren für Multi-Material-Bauweisen hergestellt mittels Materialextrusion. PhD thesis. Universitätsbibliothek Braunschweig. (2019). https://doi.org/10.24355/dbbs.084-202004201049-0

Kuschmitz, S., et al.: Bereitstellung von Lösungsprinzipien für die additive Fertigung zur Unterstützung der Bauteilkonzeption in der industriellen Praxis. In: Kynast, M., Eichmann, M., Witt, G. (eds.) Rapid.Tech + FabCon 3.D International Hub for Additive Manufacturing: Exhibition + Conference + Networking, pp. 75–88. Carl Hanser Verlag GmbH & Co., KG, München (2019). https://doi.org/10.3139/9783446462441.006

Fuchs, D., et al.: Identifikation von Zielkonflikten bei der Anwendung von Potenzialen additiver Fertigungsverfahren. In: Lachmayer, R., Rettschlag, K., Kaierle, S. (eds.) Konstruktion für die Additive Fertigung 2019, vol. 65, pp. 223–244. Springer, Berlin, Heidelberg (2020). https://doi.org/10.1007/978-3-662-61149-4_14

Bahnini, I., et al.: Computer-aided design (CAD) compensation through modeling of shrinkage in additively manufactured parts. The Int. J. Adv. Manuf. Technol. 106(9), 3999–4009 (2020)

Pahl, G., et al.: Engineering design: a systematic approach. Solid mechanics and its applications. Springer, London (2007)

Shapiro, V.: Solid modeling. In: Farin, G., Hoscheck, J., and Kim, M.-S. (Eds.), Handbook of computer aided geometric design. Elsevier, pp. 473–518 (2002). https://doi.org/10.1016/B978-044451104-1/50021-6

Kobbelt, L., Botsch, M.: Freeform shape representations for efficient geometry processing. Shape Model. Int. 2003, 111–115 (2003). https://doi.org/10.1109/SMI.2003.1199607

Requicha, A.G., Voelcker, H.: Solid modeling: current status and research directions. IEEE Comput. Graph. Appl. 3(7), 25–37 (1983). https://doi.org/10.1109/MCG.1983.263271

Mäntylä, M.: An introduction to solid modeling. In: Rockville, Md. (Ed.) Principles of computer science series, vol. 13. Computer Science Press (1988)

Hoffmann, C. M.: Geometric and solid modeling: An introduction. 2nd. print. Morgan Kaufmann series in computer graphics and geometric modeling. San Mateo, Morgan Kaufmann, Calif (1993)

Golovanov, N.: Geometric Modeling: the mathematics of shapes. [Place of publication not identified]: CreateSpace Independent Publishing Platform (2014)