Abstract

Complex-oxide materials exhibit a vast range of functional properties desirable for next-generation electronic, spintronic, magnetoelectric, neuromorphic, and energy conversion storage devices1,2,3,4. Their physical functionalities can be coupled by stacking layers of such materials to create heterostructures and can be further boosted by applying strain5,6,7. The predominant method for heterogeneous integration and application of strain has been through heteroepitaxy, which drastically limits the possible material combinations and the ability to integrate complex oxides with mature semiconductor technologies. Moreover, key physical properties of complex-oxide thin films, such as piezoelectricity and magnetostriction, are severely reduced by the substrate clamping effect. Here we demonstrate a universal mechanical exfoliation method of producing freestanding single-crystalline membranes made from a wide range of complex-oxide materials including perovskite, spinel and garnet crystal structures with varying crystallographic orientations. In addition, we create artificial heterostructures and hybridize their physical properties by directly stacking such freestanding membranes with different crystal structures and orientations, which is not possible using conventional methods. Our results establish a platform for stacking and coupling three-dimensional structures, akin to two-dimensional material-based heterostructures, for enhancing device functionalities8,9.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Spaldin, N. A. & Ramesh, R. Advances in magnetoelectric multiferroics. Nat. Mater. 18, 203–212 (2019).

Leung, C. M., Li, J., Viehland, D. & Zhuang, X. A review on applications of magnetoelectric composites: from heterostructural uncooled magnetic sensors, energy harvesters to highly efficient power converters. J. Phys. D 51, 263002 (2018).

Bauer, U., Przybylski, M., Kirschner, J. & Beach, G. S. D. Magnetoelectric charge trap memory. Nano Lett. 12, 1437–1442 (2012).

del Valle, J. et al. Subthreshold firing in Mott nanodevices. Nature 569, 388–392 (2019).

Schlom, D. G. et al. Strain tuning of ferroelectric thin films. Annu. Rev. Mater. Res. 37, 589–626 (2007).

Petrie, J. R., Jeen, H., Barron, S. C., Meyer, T. L. & Lee, H. N. Enhancing perovskite electrocatalysis through strain tuning of the oxygen deficiency. J. Am. Chem. Soc. 138, 7252–7255 (2016).

Ahadi, K. et al. Enhancing superconductivity in SrTiO3 films with strain. Sci. Adv. 5, eaaw0120 (2019).

Bae, S. H. et al. Integration of bulk materials with two-dimensional materials for physical coupling and applications. Nat. Mater. 18, 550–560 (2019).

Lee, H. et al. Direct observation of a two-dimensional hole gas at oxide interfaces. Nat. Mater. 17, 231–236 (2018).

Zubko, P., Gariglio, S., Gabay, M., Ghosez, P. & Triscone, J.-M. Interface physics in complex oxide heterostructures. Annu. Rev. Condens. Matter Phys. 2, 141–165 (2011).

Gan, Q., Rao, R. A., Eom, C. B., Garrett, J. L. & Lee, M. Direct measurement of strain effects on magnetic and electrical properties of epitaxial SrRuO3 thin films. Appl. Phys. Lett. 72, 978–980 (1998).

Boota, M., Houwman, E. P., Nguyen, M. D., Lanzara, G. & Rijnders, G. Effect of fabrication conditions on phase formation and properties of epitaxial (PbMg1/3Nb2/3O3)0.67-(PbTiO3)0.33 thin films on (001) SrTiO3. AIP Adv. 6, 055303 (2016).

Geim, A. K. & Grigorieva, I. V. Van der Waals heterostructures. Nature 499, 419–425 (2013).

Ahn, J. et al. Heterogeneous three-dimensional electronics by use of printed semiconductor nanomaterials. Science 314, 1754–1757 (2006).

Yim, K. H. et al. Efficient conjugated-polymer optoelectronic devices fabricated by thin-film transfer-printing technique. Adv. Funct. Mater. 18, 1012–1019 (2008).

Kum, H. et al. Epitaxial growth and layer-transfer techniques for heterogeneous integration of materials for electronic and photonic devices. Nat. Electron. 2, 439–450 (2019).

Lu, D. et al. Synthesis of freestanding single-crystal perovskite films and heterostructures by etching of sacrificial water-soluble layers. Nat. Mater. 15, 1255–1260 (2016).

Bakaul, S. R. et al. Single crystal functional oxides on silicon. Nat. Commun. 7, 10547 (2016).

Paskiewicz, D. M., Sichel-Tissot, R., Karapetrova, E., Stan, L. & Fong, D. D. Single-crystalline SrRuO3 nanomembranes: a platform for flexible oxide electronics. Nano Lett. 16, 534–542 (2016).

Ji, D. et al. Freestanding crystalline oxide perovskites down to the monolayer limit. Nature 570, 87–90 (2019).

Zhang, Y. et al. Flexible quasi-two-dimensional CoFe2O4 epitaxial thin films for continuous strain tuning of magnetic properties. ACS Nano 11, 8002–8009 (2017).

Kim, Y. et al. Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 544, 340–343 (2017).

Kong, W. et al. Polarity governs atomic interaction through two-dimensional materials. Nat. Mater. 17, 999–1004 (2018).

Baek, S. H. et al. Giant piezoelectricity on Si for hyperactive MEMS. Science 334, 958–961 (2011).

Subramanian, S. et al. Properties of synthetic epitaxial graphene/molybdenum disulfide lateral heterostructures. Carbon 125, 551–556 (2017).

Coy-Diaz, H., Addou, R. & Batzill, M. Interface between graphene and SrTiO3(001) investigated by scanning tunneling microscopy and photoemission. J. Phys. Chem. C 117, 21006–21013 (2013).

Schneider, C. W. et al. The origin of oxygen in oxide thin films: role of the substrate. Appl. Phys. Lett. 97, 192107 (2010).

Willmott, P. R., Herger, R., Schlepütz, C. M., Martoccia, D. & Patterson, B. D. Energetic surface smoothing of complex metal-oxide thin films. Phys. Rev. Lett. 96, 176102 (2006).

Brewer, A. et al. Uniform sputter deposition of high-quality epitaxial complex oxide thin films. J. Vac. Sci. Technol. A 35, 060607 (2017).

Chen, J. et al. Self healing of defected graphene. Appl. Phys. Lett. 102, 103107 (2013).

Li, F. et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 17, 349–354 (2018).

Krogstad, M. J. et al. The relation of local order to material properties in relaxor ferroelectrics. Nat. Mater. 17, 718–724 (2018).

Li, F. et al. Giant piezoelectricity of Sm-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. Science 1, 264–268 (2019).

Bozorth, R. M., Tilden, E. F. & Williams, A. J. Anisotropy and magnetostriction of some ferrites. Phys. Rev. 99, 1788 (1955).

Fetisov, Y. K. & Srinivasan, G. Electric field tuning characteristics of a ferrite-piezoelectric microwave resonator. Appl. Phys. Lett. 88, 143503 (2006).

Chu, Z., PourhosseiniAsl, M. & Dong, S. Review of multi-layered magnetoelectric composite materials and devices applications. J. Phys. D 51, 243001 (2018).

Irwin, J. et al. Magnetoelectric coupling by piezoelectric tensor design. Sci. Rep. 9, 19158 (2019).

Feng, M., Wang, W., Zhou, Y., Li, H. & Jia, D. Influence of residual stress on magnetoelectric coupling of bilayered CoFe2O4/PMN-PT thin films. J. Mater. Chem. 21, 10738–10743 (2011).

Wang, Z. et al. Domain rotation induced strain effect on the magnetic and magneto-electric response in CoFe2O4/Pb(Mg,Nb)O3-PbTiO3 heterostructures. J. Appl. Phys. 111, 034108 (2012).

Hallal, A., Ibrahim, F., Yang, H., Roche, S. & Chshiev, M. Tailoring magnetic insulator proximity effects in graphene: first-principles calculations. 2D Mater. 4, 025074 (2017).

Das, A. et al. Monitoring dopants by Raman scattering in an electrochemically top-gated graphene transistor. Nat. Nanotechnol. 3, 210–215 (2008).

Kim, J. & Xie, Y. H. Fabrication of dislocation-free tensile strained Si thin films using controllably oxidized porous Si substrates. Appl. Phys. Lett. 89, 152117 (2006).

Suo, Z. & Hutchinson, J. W. Steady-state cracking in brittle substrates beneath adherent films. Int. J. Solids Struct. 25, 1337–1353 (1989).

Bu, S. D. et al. Perovskite phase stabilization in epitaxial Pb(Mg1/3Nb2/3)O3-PbTiO3 films by deposition onto vicinal (001) SrTiO3 substrates. Appl. Phys. Lett. 79, 3482–3484 (2001).

Eom, C. B. et al. In situ grown YBa2Cu3O7-d thin films from single-target magnetron sputtering. Appl. Phys. Lett. 55, 595–597 (1989).

Vopson, M. M., Fetisov, Y. K., Caruntu, G. & Srinivasan, G. Measurement techniques of the magneto-electric coupling in multiferroics. Materials 10, 963 (2017).

Acknowledgements

The team at MIT and the University of Wisconsin-Madison acknowledge support primarily by the Defense Advanced Research Projects Agency (DARPA) (award number 027049-00001, W. Carters and J. Gimlett). The work at University of Wisconsin-Madison is also supported by the Army Research Office through grant W911NF-17-1-0462. C.A.R. and J.B. acknowledge support from the SMART Center sponsored by NIST and SRC. J.A.R. and S. Subramanian acknowledge support from NSF CAREER award 1453924. J.H.L. acknowledges support from a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (number 2018R1D1A1B07050484). The work at Cornell University is supported by the National Science Foundation (Platform for the Accelerated Realization, Analysis and Discovery of Interface Materials (PARADIM)) under Cooperative Agreement Number DMR-1539918. J.K. thanks the Masdar Institute/Khalifa University, the LG Electronics R&D Center, Amore Pacific, the LAM Research Foundation, Analogue Devices, and Rocky Mountain Vacuum Tech for general support. We are grateful to J. Li for assistance with the TEM measurements. We especially thank R. Bliem and B. Yildiz of MIT for early help in preparation of STO films.

Author information

Authors and Affiliations

Contributions

J.K. and C.B.E. conceived the idea and directed the team. H.S.K. designed and coordinated the experiments and characterization. H.S.K., H. Lee., S. Lindemann, W.K. and K.Q. performed epitaxial growth (pulsed-laser deposition and sputtering), characterization and heterogeneous integration development under the guidance of C.-B.E. and J.K. Epitaxial growth via MBE was performed by J.H.L. and S.X. under the guidance of D.G.S. Material characterization was done by H.S.K., P.C., L.R., S. Seo, C.C., S.-H.B. and K.L. Magnetoelectric coupling data analyses were performed by H.S.K, J.I. under the guidance of M.S.R. Device fabrication was carried out by H.S.K. and J.S. Magnetostatic and magnetoelastic data were analysed by H.S.K, S. Lee and J.B. under the guidance of C.A.R. The epitaxial graphene was grown by S. Subramanian under the guidance of J.A.R. Density functional theory calculations were performed by H. Li. All TEM imaging and analyses were performed by S.K. The manuscript was written by H.S.K., J.K. and C.B.E. All authors contributed to the analysis and discussion of the results leading to the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks Jay Switzer and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

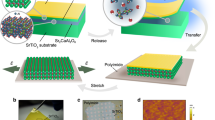

Extended Data Fig. 1 Density functional theory simulation of substrate surface potential penetrating through graphene layers on a STO substrate.

a, Illustration of the simulated structure. b, The potential fluctuation through graphene as a function of monolayer (1ML) and bilayer (2ML) graphene thickness d. The inset shows the potential fluctuation map on the surface of graphene-coated STO substrates for monolayer graphene (left) and bilayer graphene (right). c, The potential fluctuation map (colour scale) with three monolayers of graphene on top of the STO surface. d, Cross-sectional potential profile along the red line shown in c.

Extended Data Fig. 2 Pulsed-laser deposition of STO on graphene-coated STO substrate.

a, RHEED pattern during growth of STO on graphene-coated STO substrate, showing crystalline growth through the entire growth process. The yellow arrows indicate RHEED patterns caused by the transferred graphene. b, RHEED oscillation during the growth of STO on the graphene-coated STO substrate.

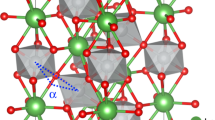

Extended Data Fig. 3 Cross-sectional TEM analysis of exfoliated STO membrane.

a, Low-magnification TEM image of STO membrane supported by the Ni stressor layer. b, Zoom-in of polycrystalline domains caused by residues left on graphene after transfer. c, High-resolution TEM image of the STO membrane (centre), with selected area electron diffraction (left) and high-resolution TEM (right) images, confirming the overall single-crystallinity of the membrane. The single-crystalline STO membrane has a cubic structure in the \(Pm\bar{3}m\) space group with lattice distances d100 and d001 of 0.4 nm.

Extended Data Fig. 4 STEM analysis of the SrTiO3 buffer layer grown in vacuum.

a, and b, show the bright-field (BF) and HAADF-STEM images of the exfoliated STO membrane (the same TEM sample as shown in Extended Data Fig. 3) at low magnification, respectively. c and d show higher-resolution bright-field and HAADF-STEM images of the sample, respectively. e, Electron energy loss spectroscopy spectra and line profile from the exfoliated surface to the bulk region (A–B in d), verifying that the composition of the buffer layer grown in vacuum is identical to the region grown under oxygen overpressure. f, High-resolution HAADF, showing individual atoms of the STO membrane at the exfoliation surface (the region grown in vacuum). The annular bright-field (ABF) and contrast inverted annular bright-field images (g and h, respectively) clearly show the absence of oxygen vacancies and no discernible differences are observed between the regions grown in vacuum and in oxygen.

Extended Data Fig. 5 Cross-sectional TEM analysis of exfoliated CFO membrane.

a, Cross-sectional TEM of exfoliated CFO on the Ti/Ni stressor layer. The red dotted line indicates a polycrystalline domain caused by residues left during graphene transfer. b, Zoomed-in TEM of the polycrystalline area marked by red dotted lines. c, Higher-resolution cross-sectional TEM of the CFO film (centre), with selected area electron diffraction (left) and high-resolution TEM (right) images, confirming the overall single-crystallinity of the membrane. The single-crystalline CFO membrane has a cubic structure in the \(Fd\bar{3}m\) space group with a lattice distance d200 and d002 of 0.41 nm.

Extended Data Fig. 6 Exfoliation and characterization of BaTiO3 membrane grown via MBE.

a, Photograph of exfoliated BTO membrane (50 nm) grown via remote epitaxy. b, EBSD of the exfoliated BTO membrane showing single-crystalline (100) orientation. c, The inverse-pole map of the EBSD data shown in b. d, Electron backscattering patterns (also known as Kikuchi patterns) of the BTO membrane seen over the entire area of the sample.

Extended Data Fig. 7 Reusability of a graphene-coated MAO substrate.

a, b, Microscope images of a MAO substrate after exfoliating a CFO film grown on monolayer (a) and bilayer (b) graphene, where severe damage on the surface of the MAO substrate after exfoliation of CFO grown on monolayer graphene was observed, caused by crack propagation into the substrate. No evidence of damage was observed on substrates coated with bilayer graphene because the second graphene transfer covers the macroscopic defective areas of the first graphene layer. The scale bar indicates 1 mm. c, AFM of the pristine MAO substrate surface (left) and after one cycle of CFO exfoliation (right) with a root-mean-square roughness of approximately 5.5 Å before and after exfoliation. Scale bar indicates 1 µm. d, e, Raman spectra showing the characteristic D peak, G peak and 2D peak of graphene (d) and Raman intensity mapping (e) of the 2D peak (2,685 cm−1) of graphene on the MAO substrate after one cycle of CFO exfoliation, showing evidence that graphene is preserved on the MAO substrate after exfoliation, probably because the non-specific adhesion between graphene and CFO is weaker than that between graphene and MAO. Where this is not the case, we could etch off any graphene remaining on the substrate and re-deposit graphene before epitaxy. The scale bar indicates 10 µm. f, Magnetic hysteresis M of the three exfoliated CFO membranes produced on a single graphene-coated MAO substrate measured by vibrating sample magnetometry at room temperature. a.u., arbitrary units.

Extended Data Fig. 8 STEM imaging and strain analysis of the PMN-PT/SRO/STO interfaces.

a, b, Cross-sectional HAADF-STEM images of the PMN-PT/SRO/STO interfaces with and without a Ni stressor layer. Clear straining at the PMN-PT/SRO interface can be seen with a Ni stressor layer, whereas the SRO/STO interface remains unstrained. c, Atomic-resolution STEM image of one of the periodic edge dislocations observed at the PMN-PT/SRO interface. d, Geometric phase analysis of the PMN-PT/SRO and SRO/STO interfaces in the x direction (2nd column), y direction (3rd column) and rotational geometry (last column) with and without the Ni stressor layer. The white arrows indicate edge dislocations. The colour scale indicates the strain fraction with reference to the SRO substrate.

Extended Data Fig. 9 Description of the in situ TEM CFO/PMN-PT heterostructure device.

a, A cross-sectional SEM of the in situ CFO/PMN-PT magnetoelectric device. A thick Pt layer (labelled TEM probe contact) was deposited on top of the 7-nm-thick Pt layer to enable the TEM probe tip to establish electrical contact. The TEM probe contact was intentionally made much thicker and further away from the actively observed region (distance greater than 5 µm) to prevent effects caused by bending of the sample. b, High-resolution TEM image of the CFO/Pt/PMN-PT interface, showing a thin amorphous oxide layer that has formed between the CFO and Pt, enabling efficient strain coupling.

Extended Data Fig. 10 CFO magnetic hysteresis as a function of voltage applied across PMN-PT.

CFO magnetism with a varying voltage bias across a PMN-PT measured via vibrating sample magnetometry. a, In the clamped structure, the PMN-PT film is grown on a SRO/STO substrate, and the CFO membrane is transferred on top of a thin Pt layer deposited on top of PMN-PT. b, In the freestanding structure, the PMN-PT membrane is transferred onto a PDMS substrate after exfoliation. The rest of the stack is identical.

Supplementary information

Supplementary Information

This file contains Supplementary Section 1, the graphene transfer process and Supplementary Section 2, Supplementary Figures 1-5.

Video 1

In situ TEM of (100) CFO as a function of voltage applied across (100) PMN-PT for a freestanding CFO/PMN-PT magnetoelectric coupled membrane device. The voltage is swept from 0 to 10 V.

Rights and permissions

About this article

Cite this article

Kum, H.S., Lee, H., Kim, S. et al. Heterogeneous integration of single-crystalline complex-oxide membranes. Nature 578, 75–81 (2020). https://doi.org/10.1038/s41586-020-1939-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-020-1939-z

This article is cited by

-

A 2D ferroelectric vortex pattern in twisted BaTiO3 freestanding layers

Nature (2024)

-

Heterogeneous integration of high-k complex-oxide gate dielectrics on wide band-gap high-electron-mobility transistors

Communications Engineering (2024)

-

Spatially reconfigurable antiferromagnetic states in topologically rich free-standing nanomembranes

Nature Materials (2024)

-

Twisted Integration of Complex Oxide Magnetoelectric Heterostructures via Water-Etching and Transfer Process

Nano-Micro Letters (2024)

-

Applications of remote epitaxy and van der Waals epitaxy

Nano Convergence (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.