Abstracts

Food processes must ensure safety and high-quality products for a growing demand consumer creating the need for better knowledge of its unit operations. The Computational Fluid Dynamics (CFD) has been widely used for better understanding the food thermal processes, and it is one of the safest and most frequently used methods for food preservation. However, there is no single study in the literature describing thermal process of liquid foods in a brick shaped package. The present study evaluated such process and the influence of its orientation on the process lethality. It demonstrated the potential of using CFD to evaluate thermal processes of liquid foods and the importance of rheological characterization and convection in thermal processing of liquid foods. It also showed that packaging orientation does not result in different sterilization values during thermal process of the evaluated fluids in the brick shaped package.

mathematical modeling; computational fluid dynamics (CFD); process optimization; thermal process; sterilization

O processamento de alimentos deve garantir segurança e qualidade a um consumidor cada vez mais exigente, criando a necessidade de melhor entendimento das operações unitárias envolvidas nessa produção. A fluidodinâmica computacional (CFD) tem sido bastante usada para entendimento de processos térmicos de alimentos, ainda o método mais seguro e utilizado para conservação de alimentos. Mesmo assim, nenhum estudo da literatura descreve o processo térmico de alimentos líquidos em embalagens com geometria prismático retangular. O presente trabalho avaliou tal processo, assim como a influência da orientação da embalagem na eficiência do processo, demonstrando o potencial da utilização da CFD na avaliação de processos térmicos de alimentos líquidos, assim como a importância das propriedades reológicas e da convecção natural na eficiência deles. Além disso, mostrou que a orientação da embalagem não resulta em diferenças na eficiência do processo avaliado.

modelos matemáticos; fluidodinâmica computacional (CFD); otimização de processos; processos térmicos; esterilização

Computational fluid dynamics evaluation of liquid food thermal process in a brick shaped package

Utilização de fluidodinâmica computacional na avaliação de processos térmicos de alimentos líquidos em embalagens prismático retangulares

Pedro Esteves Duarte AugustoI,II,* * Corresponding author ; Marcelo CristianiniI

IDepartment of Food Technology, School of Food Engineering, University of Campinas UNICAMP, Campinas, SP, Brazil

IITechnical School of Campinas, University of Campinas UNICAMP, Rua Culto à Ciência, 177, Bairro Botafogo, CEP 13020-060, Campinas, SP, Brazil,

e-mail: pedro@cotuca.unicamp.br

ABSTRACT

Food processes must ensure safety and high-quality products for a growing demand consumer creating the need for better knowledge of its unit operations. The Computational Fluid Dynamics (CFD) has been widely used for better understanding the food thermal processes, and it is one of the safest and most frequently used methods for food preservation. However, there is no single study in the literature describing thermal process of liquid foods in a brick shaped package. The present study evaluated such process and the influence of its orientation on the process lethality. It demonstrated the potential of using CFD to evaluate thermal processes of liquid foods and the importance of rheological characterization and convection in thermal processing of liquid foods. It also showed that packaging orientation does not result in different sterilization values during thermal process of the evaluated fluids in the brick shaped package.

Keywords: mathematical modeling; computational fluid dynamics (CFD); process optimization; thermal process; sterilization.

RESUMO

O processamento de alimentos deve garantir segurança e qualidade a um consumidor cada vez mais exigente, criando a necessidade de melhor entendimento das operações unitárias envolvidas nessa produção. A fluidodinâmica computacional (CFD) tem sido bastante usada para entendimento de processos térmicos de alimentos, ainda o método mais seguro e utilizado para conservação de alimentos. Mesmo assim, nenhum estudo da literatura descreve o processo térmico de alimentos líquidos em embalagens com geometria prismático retangular. O presente trabalho avaliou tal processo, assim como a influência da orientação da embalagem na eficiência do processo, demonstrando o potencial da utilização da CFD na avaliação de processos térmicos de alimentos líquidos, assim como a importância das propriedades reológicas e da convecção natural na eficiência deles. Além disso, mostrou que a orientação da embalagem não resulta em diferenças na eficiência do processo avaliado.

Palavras-chave: modelos matemáticos; fluidodinâmica computacional (CFD); otimização de processos; processos térmicos; esterilização.

1 Introduction

Thermal processing is one of the most utilized methods for food preservation (GHANI et al., 2001a). Appertization is still the most effective conservation method, even when compared to recently advanced techniques (FARID; GHANI, 2004; GHANI et al., 1999a).

The liquid flow characteristics inside the packaging during heating are a function of its geometry, where even small alterations can change the process characteristics (BRANDON et al., 1984). However, little attention has been deposited on modifications in the thermal processing of liquid foods through changes in geometry or orientation of its packaging (VARMA; KANNAN, 2005, 2006). Kannan and Sandaka (2008) observed the need for better understanding the heat transfer phenomenon associated with the thermal process of liquid foods to improve the processes. Moreover, the optimization of heat transfer during the thermal processing of a determined food may result in better sensorial and nutritional characteristics at lower process costs (mainly due to energy-saving) maintaining safe consumption and attracting the consumer. According to Xia and Sun (2002), the use of mathematical modeling through Computational Fluid Dynamics (CFD) can help these evaluations and developments.

CFD is a numerical technique of solving equations which govern the fluid flow and heat transfer in a determined geometry. It consists of numerical and simultaneous resolution of the Navier-Stokes Transport Equations, which describe the conservation of mass, moment, and energy and state equations (NORTON; SUN, 2006; SCOTT; RICHARDSON, 1997). CFD has been used by several authors as a tool to evaluate thermal processes of liquid foods in cylindrical (AUGUSTO; PINHEIRO, CRISTIANINI, 2010a,b; KANNAN; SANDAKA, 2008; AUGUSTO; CRISTIANINI, 2008; VARMA; KANNAN, 2006; CHEN; HUANG; GHANI, 2005; FARID; GHANI, 2004; GHANI et al., 1999a,b, 2001b; GHANI; FARID; CHEN, 2002a,c; KUMAR; BHATTACHARYA, 1991; KUMAR; BHATTACHARYA; BLAYLOCK, 1990; DATTA; TEIXEIRA, 1987, 1988), conical (VARMA; KANNAN, 2005, 2006), and irregular shaped packages such as bottles (AUGUSTO; CRISTIANINI, 2010a,b; HORN et al., 1997; BRANDON et al., 1984; ENGELMAN; SANI, 1983) and pouches (GHANI; FARID; CHEN, 2002b; GHANI et al., 2001a). However, there are no studies in the literature describing the thermal process of liquid foods in a brick shaped package.

The present study aimed to evaluate the thermal process of a liquid food in a brick shaped package as well as the influence of its orientation on the process lethality.

2 Material and methods

The evaluated problem (fluid heat exchange and flow in a closed system) is described by Navier-Stokes Transport Equations. Navier-Stokes Equations describe the conservation of mass (law of continuity; Equation 1), momentum (Newtons second law of motion; Equations 2, 3, and 4) and energy (first law of thermodynamics; Equation 5) (NORTON; SUN, 2006; CHEN, 2006):

Conservation of mass (law of continuity):

Conservation of momentum (Newtons second law of motion) in axis x, y, and z:

Conservation of energy (first law of thermodynamics):

The problem resolution must also consider the state equations. State equations describe the physical properties of materials as a function of environmental conditions, as temperature. The Boussinesq approximation (Equation 6), which has been used successfully in many food engineering applications, describes density variation as a function of temperature only in the momentum equations (NORTON; SUN, 2006; CHEN, 2006):

Simulations were performed by CFD analysis using the Ansys CFX 12.0 program (Ansys Inc., USA) to solve the partial differential governing transport equations (Navier-Stokes Equations and state equations).

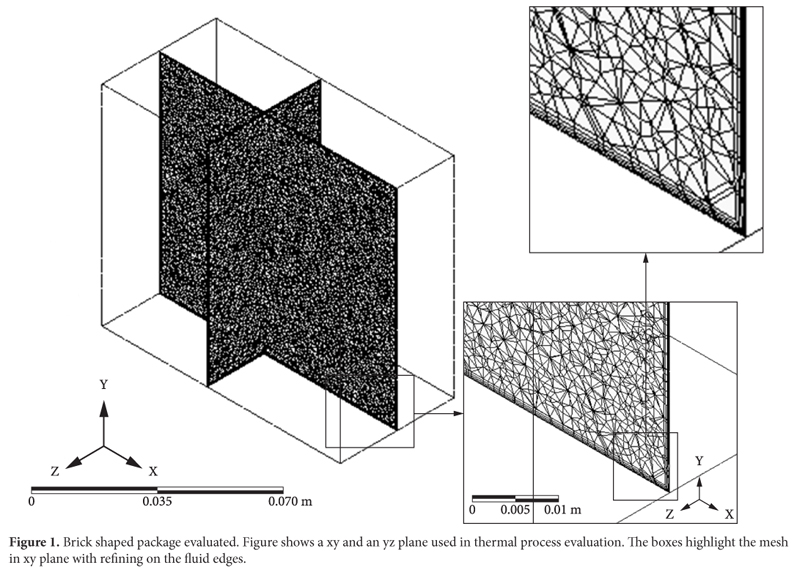

The three-dimensional model was obtained from the actual geometry of the brick shaped package, a retortable multilayer carton-based package (TETRA PAK, 2010). Its dimensions are 94 mm of height, 83 mm of depth, and 45 mm of width (in Figure 1, respectively, ∆x, ∆y, and ∆z). Due to the small thickness of the packaging, its thermal resistance was considered negligible. Water was considered as a liquid model food, and its thermal properties were used (Table 1). For packaging evaluation, it was also considered a viscous hypothetic fluid with the same physical properties of water (except for viscosity, since it was considered 10 times more viscous than water), This viscosity represents some concentrated juices and fruit products, egg products, concentrated milk, and other foods (BARBOSA-CÁNOVAS; IBARZ; PELEG, 1993). Moreover, the physical properties of water for a solid material were considered as well enabling the comparison of the importance of convection in its materials process.

The unstructured tetrahedral mesh was generated with refining on the fluid borders, a region with larger temperature and velocity gradient, as normally used. The maximum dimension of the elements generated was 2 mm (VARMA; KANNAN, 2006), with refining according to a geometrical expansion factor of 1.3 (VARMA; KANNAN, 2005, 2006). Mesh was formed by 437,514 elements.

The following considerations and initial conditions, widely used in the literature (AUGUSTO; CRISTIANINI, 2010a), were used in this study:

-

Uniform initial temperature (25 ºC);

-

The velocity of the fluid convection currents on the x, y and z axes is zero at t = 0;

-

The velocity of fluid convection currents on the packaging walls is zero (no slip condition);

-

Viscous dissipation and internal generation of energy are negligible;

-

Boussinesq approximation is valid.

As boundary condition, packaging, heating, and cooling was considered to be uniform with heat flow obtained at each time step by the retort convective heat transfer coefficient (hour) and temperature (Th) based on the values obtained by Santana, Augusto and Cristianini (2011) considering the early Come Up Time (CUT), Ball time (0.42 CUT + processing time), and cooling time. The process was carried out at 121 ºC with 800 seconds of time holding.

Minimization of Root Mean Square (RMS) was used as a criterion of convergence for simulations with a maximum value of 104 (VARMA; KANNAN, 2006). The time step used was 2.0 seconds (AUGUSTO; CRISTIANINI, 2010a).

The chemical and biochemical reactions (as the microbial inactivation) involved in the thermal processes of foods have an exponential relation with the temperature. Therefore, thermal process evaluation must be carried out not only through thermal profiles, but also and especially through the resulting sterilization values (F) (AUGUSTO et al., 2009). In the case of liquid foods, in which there is a mixture of product, regions final microbial count will be the mean value of the various portions. In this case, the process can be dimensioned and evaluated through the mass average sterilization value (Fm; Equation 7), while conductive food processes must be dimensioned through the sterilization value calculated at the cold spot (Fp) (AUGUSTO; CRISTIANINI, 2008). Fm was calculated with Tref of 121.1 ºC, and the Clostridium botulinum z-value is 10 ºC.

The effectiveness of the thermal process was compared for three different package orientations, based on the three positions that the packages can be loaded in retort. Hence, gravitational acceleration was considered as 9.8 m/s in x (named gx), y (named gy), and z (named gz) directions. The temperature and velocity profiles were also evaluated in the three models, as well as in the slowest heating zone (SHZ) location.

3 Results and discussions

Figures 2 and 3 show temperature and velocity profiles for the viscous fluid in the three evaluated orientations after 300, 1000, 1550, and 2000 seconds of the process. Since water and viscous fluid show the same behavior, only the viscous fluid figures are presented.

The temperature and velocity profiles were compatible with those described in different studies on heating different products in cans and bottles, pasteurization of water in bottles (AUGUSTO; CRISTIANINI, 2010b; HORN et al., 1997; BRANDON et al., 1984; ENGELMAN; SANI, 1983; BRANDON; PELTON; STAACK, 1982; BRANDON; HULING; STAACK, 1983), sterilization of water in cylindrical cans (AUGUSTO; CRISTIANINI, 2008, 2010b; CHEN; HUANG, GHANI, 2005; GHANI et al., 1999a; DATTA; TEIXEIRA, 1987, 1988), pasteurization of water in cylindrical cans (AUGUSTO; CRISTIANINI, 2010a; BRANDON et al., 1984), sterilization of viscous fluid in cylindrical cans (AUGUSTO; CRISTIANINI, 2010b; KANNAN; SANDAKA, 2008; VARMA; KANNAN, 2005, 2006; CHEN; HUANG; GHANI, 2005; GHANI et al., 1999a,b, 2001b; GHANI; FARID; CHEN, 2002a; KUMAR; BHATTACHARYA, 1991; KUMAR; BHATTACHARYA; BLAYLOCK, 1990), and pasteurization of viscous fluid in bottles (AUGUSTO; CRISTIANINI, 2010a).

The GrashofNumber (Gr Equation 8) relates the fluid flow regime when in natural convection (FARID; GHANI, 2004) since the Reynolds Number performs it with forced convection. The Gr calculated for the processes in the present study is in the order of 107-108 for water heating and 105-106 for the viscous fluid heating. According to Ghani et al. (1999a) and Farid and Ghani (2004), at such levels one can adopt the consideration of laminar flow.

In the beginning of the process, heating of the extremities results in a large temperature gradient in the fluid and, consequently, density gradient, resulting in fluid movement in a random distribution (Figure 3). This behavior was presented even by water and the viscous fluid in the three package positions evaluated. Similar behavior has been described by Augusto, Pinheiro and Cristianini (2010a) heating water in beer cans, Ghani et al., (1999a) heating water and Carboxy-Methyl-Cellulose (CMC) suspension in cylindrical cans, Datta and Teixeira (1987,1988) heating water in cylindrical cans, and Augusto and Cristianini (2010b) and Brandon et al. (1984) and Brandon, Pelton and Staack (1982) heating water in bottles.

In this period, there is the presence and disintegration of various Benard Cells, circular flows formed due to the meeting of two or more flows (as can be seen Figure 3 for the 300 seconds of process) since the package heating is uniform through its sides. If heating is continuous, the flow tends to stabilize in a characteristic profile with a larger looping ascending in the package walls and descending in the center of the package and small ones near the center of the package base, at an opposed direction to the first. Fluid flow took almost 1000 seconds to stabilize for both fluids and for the three orientations. The same behavior is then observed during the beginning of cooling (Figure 3, as in 1550 seconds of the process).

The fluid flow points down to a coldest region called the Slowest Heating Zone (SHZ), in contrast with the cold spot characteristic of conductive products heating. The fluid temperature is distributed in layers with the hot ascending flow close to the package walls during heating. The SHZ is located in the bottom of the package during the process.

Figure 4 shows comparisons for the processes of water, viscous fluid, and the hypothetical solid, considering the three packaging orientations.

Packaging orientation was evaluated due to the large differentiation of its dimensions (94 mm of height, 83 mm of depth, and 45 mm of width), which results in a difference of one order of magnitude in Grashof number (Gr) and Rayleigh number (Ra). The Rayleigh number (Ra) is obtained by multiplying Grashof number (Gr) and Prandt number (Pr; Prandt number relates the ratio of momentum diffusivity - kinematic viscosity, and thermal diffusivity), showing the importance of convection in a heat transfer fluid process. Thus, orientation can be important in asymmetric packages thermal processes since it can result in different sterilization values.

As can be seen in Figure 4, for the same process and fluid, orientation does not result in different sterilization values (Fm). This behavior is similar to water pasteurization in beer cans (AUGUSTO; CRISTIANINI, 2010a) and bottles (AUGUSTO; CRISTIANINI, 2010b), but contrary to the sterilization of consistent liquid foods in conical (Varma and Kannan, 2006 and 2005) and cylindrical (GHANI; FARID; CHEN, 2002a) cans.

This difference can be attributed to the convection flow inside packaging, which is highly influenced by its geometry and by the evaluation itself. Varma and Kannan (2005, 2006) and Ghani, Farid and Chen (2002a) evaluated the orientation by temperature profiles. Although comparison among the efficiencies in the thermal processes should be done through sterilization values (AUGUSTO et al., 2009), this approach is rarely adopted. We highlight once more that liquid food thermal process efficiency must be evaluated by its mass average sterilization value (Fm).

For the same process, water sterilization values were 13% higher than that of the viscous fluid, and it is 7.5 times higher if natural convection is not considered (i.e., the hypothetic solid). Those results clearly show the importance of convection in those processes and the need for appropriate rheological properties consideration. Similar observations were recently made by Augusto and Cristianini (2010b), and Erdoğdu, Uyar and Palazoğlu (2010), and Koribilli, Aravamudan and Varadhan (2009), who evaluated the relative importance of convection in thermal process of liquid foods. Moreover, these authors highlighted that the approximation of fluid products by conduction model in process evaluation is not acceptable although Koribilli, Aravamudan and Varadhan (2009) observe that this simplification is sometimes used for quick estimations.

4 Conclusions

The present study showed, for the first time, the internal thermal and velocity profiles of liquid foods thermally processed in a brick shaped package, as well as its sterilization values due to processing. The results obtained demonstrate the potential of using Computational Fluid Dynamics (CFD) to evaluate thermal processes of liquid foods, especially in new or non-conventional packaging geometries. It also demonstrates the importance of rheological characterization and convection in thermal processing of liquid foods. It can be concluded that packaging orientation did not result in different sterilization values during thermal process of the evaluated fluids in the brick shaped package.

Nomenclature

β =

ρ =

γ =

µ =

a =

Cp =

g =

k =

L =

p =

t =

T =

Tref =

Th =

v =

V =

x, y and z =

z =

CUT =

Gr =

Pr =

Ra =

Acknowledgements

The authors are grateful for the financial support provided by FAPESP (São Paulo Research Foundation (project # 2007/04121-6) and present their tribute to Nicolas Appert for celebrating 200 years of Appertization.

References

AUGUSTO, P. E. D; CRISTIANINI, M. Thermal history errors evaluation in heat processed foods with internal temperature registrors. Brazilian Journal of Food Technology, v. VII BMCFB, p. 9-19, 2008. (in portuguese)

AUGUSTO, P. E. D.; CRISTIANINI, M. Evaluation of geometric symmetry condition in numerical simulations of thermal process of packed liquid food by computational fluid dynamics (CFD). International Journal of Food Engineering, v. 6, n. 5, 2010a. http://dx.doi.org/10.2202/1556-3758.1695

AUGUSTO, P. E. D.; CRISTIANINI, M. Computational fluid dynamics analysis of viscosity influence on thermal in-package liquid food process. International Journal of Food Engineering, v. 6, n. 6, 2010b. http://dx.doi.org/10.2202/1556-3758.2140

AUGUSTO, P. E. D.; PINHEIRO, T. F.; CRISTIANINI, M. Using computational fluid-dynamics (CFD) on the evaluation of beer pasteurization: effect of can orientation. Ciência e Tecnologia de Alimentos, v. 30, n.4, p. 980-986, 2010a. http://dx.doi.org/10.1590/S0101-20612010000400022

AUGUSTO, P. E. D.; PINHEIRO, T. F.; CRISTIANINI, M. Utilização de fluidodinâmica computacional (CFD) na avaliação de tratamentos térmicos de bebidas em garrafas. Brazilian Journal of Food Technology, v. 13, n. 4, p. 260-270, 2010b.

AUGUSTO, P. E. D. et al. Evaluation of methodologies for mathematical modeling of packaged conductive foods heat process. International Journal of Food Engineering, v. 5, n. 4, 2009. http://dx.doi.org/10.2202/1556-3758.1458

BARBOSA-CÁNOVAS, G. V.; IBARZ, A.; PELEG, M. Propiedades reológicas de alimentos fluidos: revision. Alimentaria, v. 241, p. 39-89, 1993.

BRANDON, H.; PELTON, P.; STAACK, G. State-of-the-art methodology for evaluating pasteurizer heating and cooling processes. MBAA Technical Quarterly, v. 19, n. 1, 34-40, 1982.

BRANDON, H.; HULING, J.; STAACK, G. Computer simulation of pasteurizer performance. MBAA Technical Quarterly, v. 20, n. 1, p. 39-46, 1983.

BRANDON, H. et al. Time-dependent modeling of in-package pasteurization. MBAA Technical Quarterly, v. 21, n. 4, p. 153-159, 1984.

CHEN, X. D.; HUANG, H. J.; GHANI, A. G. A. Thermal sterilization of liquid foods in a sealed container developing simple correlations to account for natural convection. International Journal of Food Engineering, v. 1, n. 1, 2005. http://dx.doi.org/10.2202/1556-3758.1006

CHEN, X. D. Modeling thermal processing using computational fluid dynamics (CFD). In: SUN, D. W. Thermal food processing: new technologies and quality issues. Boca Raton: CRC Press, 2006.

DATTA, A. K.; TEIXEIRA, A. A. Numerical modeling of natural convection heating in canned liquid foods. Transactions of the ASAE, v. 30, n. 5, p. 1542-1551, 1987. http://dx.doi.org/10.1111/j.1365-2621.1988.tb10206.x

DATTA, A. K.; TEIXEIRA, A. A. Numerically predicted transient temperature and velocity profiles during natural convection heating of canned liquid foods. Journal of Food Science, v. 53, n. 1, p. 191-195, 1988.

DENYS, S.; PIETERS, J. G.; DEWETTINK, K. Combined CFD and experimental approach for determination of the surface heat transfer coefficient during thermal processing of eggs. Journal of Food Science, v. 68, n. 3, p. 943-51, 2003. http://dx.doi.org/10.1111/j.1365-2621.2003.tb08269.x

ENGELMAN, M. S.; SANI, R. L. Finite-element simulation of an in-package pasteurization process. Numerical Heat Transfer, v. 6, n. 1, p. 41-54, 1983.

ERDOĞDU, F.; UYAR, R.; PALAZOĞLU, T. K. Experimental comparison of natural convection and conduction heat transfer. Journal of Food Process Engineering, v. 33, p. 85-100, 2010. Supllement 1.

FARID, M.; GHANI, A. G. A. A new computational technique for the estimation of sterilization time in canned food. Chemical Engineering and Processing, v. 43, n. 4, p. 523-531, 2004. http://dx.doi.org/10.1016/j.cep.2003.08.007

GHANI, A. G. A. et al. Numerical simulation of natural convection heating of canned food by computational fluid dynamics. Journal of Food Engineering, v. 41, n. 1, p. 55-64, 1999a. http://dx.doi.org/10.1016/S0260-8774(99)00073-4

GHANI, A. G. A. et al. An investigation of deactivation of bacteria in a canned liquid food during sterilization using computational fluid dynamics (CFD). Journal of Food Engineering, v. 42, n. 4, p. 207-214, 1999b. http://dx.doi.org/10.1016/S0260-8774(99)00123-5

GHANI, A. G. A. et al. Thermal sterilization of canned food in a 3-D pouch using computational fluid dynamics. Journal of Food Engineering, v. 48, n. 2, p. 147-156, 2001a. http://dx.doi.org/10.1016/S0260-8774(00)00150-3

GHANI, A. G. A. et al. Numerical simulation of biochemical changes in a viscous liquid canned food during sterilization using computational fluid dynamics. Food Australia, v. 53, n. 1-2, p. 48-53, 2001b.

GHANI, A. G. A.; FARID, M. M.; CHEN, X. Numerical simulation of transient temperature and velocity profiles in a horizontal can during sterilization using computational fluid dynamics. Journal of Food Engineering, v. 51, n. 1, p. 77-83, 2002a. http://dx.doi.org/10.1016/S0260-8774(01)00039-5

GHANI, A. G. A.; FARID, M. M.; CHEN, X. Theoretical and experimental investigation of the thermal inactivation of Bacillus stearothermophilus in food pouches. Journal of Food Engineering, v. 51, n. 3, p. 221-228, 2002b. http://dx.doi.org/10.1016/S0260-8774(01)00060-7

GHANI, A. G. A.; FARID, M. M.; CHEN, X, D. Theoretical and experimental investigation of the thermal destruction of vitamin C in food pouches. Computers and Electronics in Agriculture, v. 34, n. 1-3, p. 129-143, 2002c. http://dx.doi.org/10.1016/S0168-1699(01)00183-1

HORN, C. S. et al. Modeling and simulation of pasteurization and staling effects during tunnel pasteurization of bottled beer. Food and Bioproducts Processing, v. 75, n. 1, p. 23-33, 1997. http://dx.doi.org/10.1205/096030897531333

KANNAN, A.; SANDAKA, P. C. G. Heat transfer analysis of canned food sterilization in a still retort. Journal of Food Engineering, v. 88, n. 2, p. 213-228, 2008. http://dx.doi.org/10.1016/j.jfoodeng.2008.02.007

KORIBILLI, N.; ARAVAMUDAN, K.; VARADHAN, M. U. S. V. A. Quantifying enhancement in heat transfer due to natural convection during canned food thermal sterilization in a still retort. Food Bioprocess Technology, 2009, in press.

KUMAR, A.; BHATTACHARYA, M.; BLAYLOCK, J. Numerical simulation of natural convection heating of canned thick viscous liquid food products. Journal of Food Science, v. 55, n. 5, p. 1403-1411, 1990. http://dx.doi.org/10.1111/j.1365-2621.1990.tb03946.x

KUMAR, A.; BHATTACHARYA, M. Transient temperature and velocity profiles in a canned non-Newtonian liquid food during sterilization in a still-cook retort. International Journal of Heat and Mass Transfer, v. 34, n. 4-5, p. 1083-96, 1991.

LIDE, D. R.; FREDERIKSE, H. P. R. CRC handbook of chemistry and physics. 76. ed. Boca Raton: CRC Press,1996. http://dx.doi.org/10.1016/0017-9310(91)90018-A

NORTON, T.; SUN, D. W. Computational fluid dynamics (CFD) an effective and efficient design and analysis tool for the food industry: a review. Trends in Food Science and Technology, v. 17, n. 11, p. 600-20, 2006. PMid:21299575. http://dx.doi.org/10.1016/j.tifs.2006.05.004

SANTANA, F. F.; AUGUSTO, P. E. D.; CRISTIANINI, M. Determination of the convective heat transfer Coefficient (h) in the sterilization of retortable pouches. International Journal of Food Engineering, v. 7, n. 1, 2011. http://dx.doi.org/10.2202/1556-3758.2157

SCOTT, G.; RICHARDSON, P. The application of computational fluid dynamics on food industry. Trends in Food Science and Technology, v. 8, n. 4, p. 119-124, 1997. PMid:21299575. http://dx.doi.org/10.1016/S0924-2244(97)01028-5

SENGERS, J. V.; WATSON, J. T. R. Improved international formulations for the viscosity and thermal conductivity of water substance. Journal of Physical and Chemical Reference Data, v. 15, n. 4, p. 1291-1314, 1986. http://dx.doi.org/10.1063/1.555763

Tetra Pak. Tetra Recart: the 21st century alternative for canned food. Disponível em: <http://www.tetrapak.com/products–and–services/packages/tetra–recart/pages/default.aspx>. Acesso em: 14 abr. 2010.

VARMA, M. N.; KANNAN, A. Enhanced food sterilization through inclination of the container walls and geometry modifications. International Journal of Heat and Mass Transfer, v. 48, n. 18, p. 3753-3762, 2005. http://dx.doi.org/10.1016/j.ijheatmasstransfer.2005.03.024

VARMA, M. N.; KANNAN, A. CFD studies on natural convective heating of canned food in conical and cylindrical containers. Journal of Food Engineering, v. 77, n. 4, p. 1024-1023, 2006. http://dx.doi.org/10.1016/j.jfoodeng.2005.07.035

XIA, B.; SUN, D. W. Applications of computational fluid dynamics (CFD) in the food industry: a review. Computers and Electronics in Agriculture, v. 34, n. 1-3, p. 5-24, 2002. http://dx.doi.org/10.1016/S0168-1699(01)00177-6

Received 9/8/2010

Accepted 8/11/2011 (004970)

- AUGUSTO, P. E. D; CRISTIANINI, M. Thermal history errors evaluation in heat processed foods with internal temperature registrors. Brazilian Journal of Food Technology, v. VII BMCFB, p. 9-19, 2008. (in portuguese)

- AUGUSTO, P. E. D.; CRISTIANINI, M. Evaluation of geometric symmetry condition in numerical simulations of thermal process of packed liquid food by computational fluid dynamics (CFD). International Journal of Food Engineering, v. 6, n. 5, 2010a. http://dx.doi.org/10.2202/1556-3758.1695

- AUGUSTO, P. E. D.; CRISTIANINI, M. Computational fluid dynamics analysis of viscosity influence on thermal in-package liquid food process. International Journal of Food Engineering, v. 6, n. 6, 2010b. http://dx.doi.org/10.2202/1556-3758.2140

- AUGUSTO, P. E. D.; PINHEIRO, T. F.; CRISTIANINI, M. Using computational fluid-dynamics (CFD) on the evaluation of beer pasteurization: effect of can orientation. Ciência e Tecnologia de Alimentos, v. 30, n.4, p. 980-986, 2010a. http://dx.doi.org/10.1590/S0101-20612010000400022

- AUGUSTO, P. E. D.; PINHEIRO, T. F.; CRISTIANINI, M. Utilização de fluidodinâmica computacional (CFD) na avaliação de tratamentos térmicos de bebidas em garrafas. Brazilian Journal of Food Technology, v. 13, n. 4, p. 260-270, 2010b.

- AUGUSTO, P. E. D. et al. Evaluation of methodologies for mathematical modeling of packaged conductive foods heat process. International Journal of Food Engineering, v. 5, n. 4, 2009. http://dx.doi.org/10.2202/1556-3758.1458

- BARBOSA-CÁNOVAS, G. V.; IBARZ, A.; PELEG, M. Propiedades reológicas de alimentos fluidos: revision. Alimentaria, v. 241, p. 39-89, 1993.

- BRANDON, H.; PELTON, P.; STAACK, G. State-of-the-art methodology for evaluating pasteurizer heating and cooling processes. MBAA Technical Quarterly, v. 19, n. 1, 34-40, 1982.

- BRANDON, H.; HULING, J.; STAACK, G. Computer simulation of pasteurizer performance. MBAA Technical Quarterly, v. 20, n. 1, p. 39-46, 1983.

- BRANDON, H. et al. Time-dependent modeling of in-package pasteurization. MBAA Technical Quarterly, v. 21, n. 4, p. 153-159, 1984.

- CHEN, X. D.; HUANG, H. J.; GHANI, A. G. A. Thermal sterilization of liquid foods in a sealed container developing simple correlations to account for natural convection. International Journal of Food Engineering, v. 1, n. 1, 2005. http://dx.doi.org/10.2202/1556-3758.1006

- CHEN, X. D. Modeling thermal processing using computational fluid dynamics (CFD). In: SUN, D. W. Thermal food processing: new technologies and quality issues. Boca Raton: CRC Press, 2006.

- DATTA, A. K.; TEIXEIRA, A. A. Numerical modeling of natural convection heating in canned liquid foods. Transactions of the ASAE, v. 30, n. 5, p. 1542-1551, 1987. http://dx.doi.org/10.1111/j.1365-2621.1988.tb10206.x

- DATTA, A. K.; TEIXEIRA, A. A. Numerically predicted transient temperature and velocity profiles during natural convection heating of canned liquid foods. Journal of Food Science, v. 53, n. 1, p. 191-195, 1988.

- DENYS, S.; PIETERS, J. G.; DEWETTINK, K. Combined CFD and experimental approach for determination of the surface heat transfer coefficient during thermal processing of eggs. Journal of Food Science, v. 68, n. 3, p. 943-51, 2003. http://dx.doi.org/10.1111/j.1365-2621.2003.tb08269.x

- ENGELMAN, M. S.; SANI, R. L. Finite-element simulation of an in-package pasteurization process. Numerical Heat Transfer, v. 6, n. 1, p. 41-54, 1983.

- ERDOĞDU, F.; UYAR, R.; PALAZOĞLU, T. K. Experimental comparison of natural convection and conduction heat transfer. Journal of Food Process Engineering, v. 33, p. 85-100, 2010. Supllement 1.

- FARID, M.; GHANI, A. G. A. A new computational technique for the estimation of sterilization time in canned food. Chemical Engineering and Processing, v. 43, n. 4, p. 523-531, 2004. http://dx.doi.org/10.1016/j.cep.2003.08.007

- GHANI, A. G. A. et al. Numerical simulation of natural convection heating of canned food by computational fluid dynamics. Journal of Food Engineering, v. 41, n. 1, p. 55-64, 1999a. http://dx.doi.org/10.1016/S0260-8774(99)00073-4

- GHANI, A. G. A. et al. An investigation of deactivation of bacteria in a canned liquid food during sterilization using computational fluid dynamics (CFD). Journal of Food Engineering, v. 42, n. 4, p. 207-214, 1999b. http://dx.doi.org/10.1016/S0260-8774(99)00123-5

- GHANI, A. G. A. et al. Thermal sterilization of canned food in a 3-D pouch using computational fluid dynamics. Journal of Food Engineering, v. 48, n. 2, p. 147-156, 2001a. http://dx.doi.org/10.1016/S0260-8774(00)00150-3

- GHANI, A. G. A. et al. Numerical simulation of biochemical changes in a viscous liquid canned food during sterilization using computational fluid dynamics. Food Australia, v. 53, n. 1-2, p. 48-53, 2001b.

- GHANI, A. G. A.; FARID, M. M.; CHEN, X. Numerical simulation of transient temperature and velocity profiles in a horizontal can during sterilization using computational fluid dynamics. Journal of Food Engineering, v. 51, n. 1, p. 77-83, 2002a. http://dx.doi.org/10.1016/S0260-8774(01)00039-5

- GHANI, A. G. A.; FARID, M. M.; CHEN, X. Theoretical and experimental investigation of the thermal inactivation of Bacillus stearothermophilus in food pouches. Journal of Food Engineering, v. 51, n. 3, p. 221-228, 2002b. http://dx.doi.org/10.1016/S0260-8774(01)00060-7

- GHANI, A. G. A.; FARID, M. M.; CHEN, X, D. Theoretical and experimental investigation of the thermal destruction of vitamin C in food pouches. Computers and Electronics in Agriculture, v. 34, n. 1-3, p. 129-143, 2002c. http://dx.doi.org/10.1016/S0168-1699(01)00183-1

- HORN, C. S. et al. Modeling and simulation of pasteurization and staling effects during tunnel pasteurization of bottled beer. Food and Bioproducts Processing, v. 75, n. 1, p. 23-33, 1997. http://dx.doi.org/10.1205/096030897531333

- KANNAN, A.; SANDAKA, P. C. G. Heat transfer analysis of canned food sterilization in a still retort. Journal of Food Engineering, v. 88, n. 2, p. 213-228, 2008. http://dx.doi.org/10.1016/j.jfoodeng.2008.02.007

- KORIBILLI, N.; ARAVAMUDAN, K.; VARADHAN, M. U. S. V. A. Quantifying enhancement in heat transfer due to natural convection during canned food thermal sterilization in a still retort. Food Bioprocess Technology, 2009, in press.

- KUMAR, A.; BHATTACHARYA, M.; BLAYLOCK, J. Numerical simulation of natural convection heating of canned thick viscous liquid food products. Journal of Food Science, v. 55, n. 5, p. 1403-1411, 1990. http://dx.doi.org/10.1111/j.1365-2621.1990.tb03946.x

- KUMAR, A.; BHATTACHARYA, M. Transient temperature and velocity profiles in a canned non-Newtonian liquid food during sterilization in a still-cook retort. International Journal of Heat and Mass Transfer, v. 34, n. 4-5, p. 1083-96, 1991.

- LIDE, D. R.; FREDERIKSE, H. P. R. CRC handbook of chemistry and physics 76. ed. Boca Raton: CRC Press,1996. http://dx.doi.org/10.1016/0017-9310(91)90018-A

- NORTON, T.; SUN, D. W. Computational fluid dynamics (CFD) an effective and efficient design and analysis tool for the food industry: a review. Trends in Food Science and Technology, v. 17, n. 11, p. 600-20, 2006. PMid:21299575. http://dx.doi.org/10.1016/j.tifs.2006.05.004

- SANTANA, F. F.; AUGUSTO, P. E. D.; CRISTIANINI, M. Determination of the convective heat transfer Coefficient (h) in the sterilization of retortable pouches. International Journal of Food Engineering, v. 7, n. 1, 2011. http://dx.doi.org/10.2202/1556-3758.2157

- SCOTT, G.; RICHARDSON, P. The application of computational fluid dynamics on food industry. Trends in Food Science and Technology, v. 8, n. 4, p. 119-124, 1997. PMid:21299575. http://dx.doi.org/10.1016/S0924-2244(97)01028-5

- SENGERS, J. V.; WATSON, J. T. R. Improved international formulations for the viscosity and thermal conductivity of water substance. Journal of Physical and Chemical Reference Data, v. 15, n. 4, p. 1291-1314, 1986. http://dx.doi.org/10.1063/1.555763

- VARMA, M. N.; KANNAN, A. Enhanced food sterilization through inclination of the container walls and geometry modifications. International Journal of Heat and Mass Transfer, v. 48, n. 18, p. 3753-3762, 2005. http://dx.doi.org/10.1016/j.ijheatmasstransfer.2005.03.024

- VARMA, M. N.; KANNAN, A. CFD studies on natural convective heating of canned food in conical and cylindrical containers. Journal of Food Engineering, v. 77, n. 4, p. 1024-1023, 2006. http://dx.doi.org/10.1016/j.jfoodeng.2005.07.035

- XIA, B.; SUN, D. W. Applications of computational fluid dynamics (CFD) in the food industry: a review. Computers and Electronics in Agriculture, v. 34, n. 1-3, p. 5-24, 2002. http://dx.doi.org/10.1016/S0168-1699(01)00177-6

Publication Dates

-

Publication in this collection

16 Feb 2012 -

Date of issue

Mar 2012

History

-

Received

09 Aug 2010 -

Accepted

08 Nov 2011