Bottle Aging and Storage of Wines: A Review

Abstract

:1. Introduction

2. Influence of Closure

Types of Closure

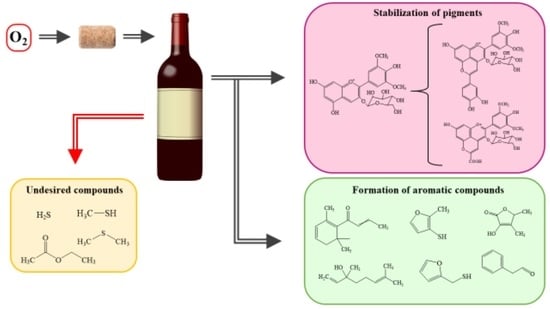

3. Oxidative Stability

4. Desired Chemical Changes

4.1. Anthocyanins

4.2. Aldehydes

4.3. Other Compounds

5. Undesired Chemical Changes

5.1. Excessive Oxidation

5.2. Reductive Faults

6. Main Factors Affecting Quality during Storage

6.1. Temperature

6.2. Light Exposure

6.3. Humidity

6.4. Position

6.5. Environmental Off-Flavors

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PC | Phenolic compounds |

| OTR | Oxygen transfer rate |

| SO2 | Sulfide dioxide |

| HSO3− | Bisulfite anion |

| SO42− | Sulfate |

| H2SO4 | Sulfuric acid |

| H2S | Hydrogen sulfide |

| MeHS | Methanethiol |

| H2O2 | Hydrogen peroxide |

| HO− | Hydroxyl radical |

| TDN | 1,1,6-trimethyl-l,2-dihydronaphthalene |

| TCA | 2,4,6-trichloroanisole |

| TBA | 2,4,6-tribromoanisole |

References

- Roullier-Gall, C.; Heinzmann, S.S.; Garcia, J.-P.; Schmitt-Kopplin, P.; Gougeon, R.D. Chemical messages from an ancient buried bottle: Metabolomics for wine archeochemistry. npj Sci. Food 2017, 1, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oliveira, C.M.; Ferreira, A.C.S.; De Freitas, V.; Silva, A.M.S. Oxidation mechanisms occurring in wines. Food Res. Int. 2011, 44, 1115–1126. [Google Scholar] [CrossRef]

- Ortega-Heras, M.; González-Sanjosé, M.L.; González-Huerta, C. Consideration of the influence of aging process, type of wine and oenological classic parameters on the levels of wood volatile compounds present in red wines. Food Chem. 2007, 103, 1434–1448. [Google Scholar] [CrossRef]

- Li, S.-Y.Y.; Duan, C.-Q.Q. Astringency, bitterness and color changes in dry red wines before and during oak barrel aging: An updated phenolic perspective review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1840–1867. [Google Scholar] [CrossRef] [PubMed]

- Astray, G.; Mejuto, J.C.; Martínez-Martínez, V.; Nevares, I.; Alamo-Sanza, M.; Simal-Gandara, J. Prediction models to control aging time in red wine. Molecules 2019, 24, 826. [Google Scholar] [CrossRef] [Green Version]

- Boulton, R.B.; Singleton, V.L.; Bisson, L.F.; Kunkee, R.E. Principles and Practices of Winemaking; Springer: Boston, MA, USA, 1999; ISBN 978-1-4419-5190-8. [Google Scholar]

- Tao, Y.; García, J.F.; Sun, D.W. Advances in Wine Aging Technologies for Enhancing Wine Quality and Accelerating Wine Aging Process. Crit. Rev. Food Sci. Nutr. 2014, 54, 817–835. [Google Scholar] [CrossRef]

- Grainger, K.; Tattersall, H. Red winemaking. In Wine Production and Quality; John Wiley & Sons, Ltd.: Chichester, UK, 2016; pp. 82–91. ISBN 9781118934562. [Google Scholar]

- International Organisation of Vine and Wine (OIV). International Code of Oenological Practices; International Organisation of Vine and Wine (OIV): Paris, France, 2017; Volume 33, ISBN 979-10-91799-73-7.

- European Comission (EC). Commission Delegated Regulation (EU) 2019/33 of 17 October 2018 Supplementing Regulation (EU) No 1308/2013. Off. J. Eur. Union 2019, 33, 2–54. [Google Scholar]

- Anli, R.E.; Cavuldak, Ö.A. A review of microoxygenation application in wine. J. Inst. Brew. 2012, 118, 368–385. [Google Scholar] [CrossRef]

- Sanz, M.; De Simón, B.F.; Cadahía, E.; Esteruelas, E.; Muñoz, Á.M.; Hernández, M.T.; Estrella, I. Polyphenolic profile as a useful tool to identify the wood used in wine aging. Anal. Chim. Acta 2012, 732, 33–45. [Google Scholar] [CrossRef]

- Fernández de Simón, B.; Cadahía, E.; del Álamo, M.; Nevares, I. Effect of size, seasoning and toasting in the volatile compounds in toasted oak wood and in a red wine treated with them. Anal. Chim. Acta 2010, 660, 211–220. [Google Scholar] [CrossRef]

- Perestrelo, R.; Silva, C.; Gonçalves, C.; Castillo, M.; Câmara, J.S. An approach of the madeira wine chemistry. Beverages 2020, 6, 12. [Google Scholar] [CrossRef] [Green Version]

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine Aging Technology: Fundamental Role of Wood Barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef] [PubMed]

- Oberholster, A.; Elmendorf, B.L.; Lerno, L.A.; King, E.S.; Heymann, H.; Brenneman, C.E.; Boulton, R.B. Barrel maturation, oak alternatives and micro-oxygenation: Influence on red wine aging and quality. Food Chem. 2015, 173, 1250–1258. [Google Scholar] [CrossRef] [PubMed]

- Farrell, R.R.; Wellinger, M.; Gloess, A.N.; Nichols, D.S.; Breadmore, M.C.; Shellie, R.A.; Yeretzian, C. Real-time mass spectrometry monitoring of oak wood toasting: Elucidating aroma development relevant to oak-aged wine quality. Sci. Rep. 2015, 5, 1–13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panero, L.; Motta, S.; Petrozziello, M.; Guaita, M.; Bosso, A. Effect of SO2, reduced glutathione and ellagitannins on the shelf life of bottled white wines. Eur. Food Res. Technol. 2014, 240, 345–356. [Google Scholar] [CrossRef]

- Alañón, M.; Díaz-Maroto, M.; Pérez-Coello, M. New Strategies to Improve Sensorial Quality of White Wines by Wood Contact. Beverages 2018, 4, 91. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez, A.; Vidal, S.; Ugliano, M. Untargeted voltammetric approaches for characterization of oxidation patterns in white wines. Food Chem. 2018, 269, 1–8. [Google Scholar] [CrossRef]

- Navarro, M.; Kontoudakis, N.; Giordanengo, T.; Gómez-Alonso, S.; García-Romero, E.; Fort, F.; Canals, J.M.; Hermosín-Gutíerrez, I.; Zamora, F. Oxygen consumption by oak chips in a model wine solution; Influence of the botanical origin, toast level and ellagitannin content. Food Chem. 2016, 199, 822–827. [Google Scholar] [CrossRef]

- Martinez, K.B.; Mackert, J.D.; McIntosh, M.K. Chapter 18—Polyphenols and Intestinal Health. In Nutrition and Functional Foods for Healthy Aging; Watson, R.R., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 191–210. ISBN 978-0-12-805376-8. [Google Scholar]

- Avizcuri, J.M.; Sáenz-Navajas, M.P.; Echávarri, J.F.; Ferreira, V.; Fernández-Zurbano, P. Evaluation of the impact of initial red wine composition on changes in color and anthocyanin content during bottle storage. Food Chem. 2016, 213, 123–134. [Google Scholar] [CrossRef] [Green Version]

- Arapitsas, P.; Speri, G.; Angeli, A.; Perenzoni, D.; Mattivi, F. The influence of storage on the “chemical age” of red wines. Metabolomics 2014, 10, 816–832. [Google Scholar] [CrossRef]

- Caillé, S.; Samson, A.; Wirth, J.; Diéval, J.B.; Vidal, S.; Cheynier, V. Sensory characteristics changes of red Grenache wines submitted to different oxygen exposures pre and post bottling. Anal. Chim. Acta 2010, 660, 35–42. [Google Scholar] [CrossRef]

- Revi, M.; Badeka, A.; Kontakos, S.; Kontominas, M.G. Effect of packaging material on enological parameters and volatile compounds of dry white wine. Food Chem. 2014, 152, 331–339. [Google Scholar] [CrossRef]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Xiaoguo, Y.; Andrich, G.; Zinnai, A. The influence of packaging on the sensorial evolution of white wine as a function of the operating conditions adopted during storage. Agrochimica 2016, 60, 150–160. [Google Scholar] [CrossRef]

- Karbowiak, T.; Crouvisier-Urion, K.; Lagorce, A.; Ballester, J.; Geoffroy, A.; Roullier-Gall, C.; Chanut, J.; Gougeon, R.D.; Schmitt-Kopplin, P.; Bellat, J.P. Wine aging: A bottleneck story. npj Sci. Food 2019, 3, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Vidal, J.-C.; Caillé, S.; Samson, A.; Salmon, J.-M. Comparison of the effect of 8 closures in controlled industrial conditions on the shelf life of a red wine. BIO Web Conf. 2017, 9, 02024. [Google Scholar] [CrossRef] [Green Version]

- Strobl, M. Red Wine Bottling and Packaging. Red Wine Technol. 2018, 323–339. [Google Scholar] [CrossRef]

- Oliveira, A.S.; Furtado, I.; de Lourdes Bastos, M.; Guedes de Pinho, P.; Pinto, J. The influence of different closures on volatile composition of a white wine. Food Packag. Shelf Life 2020, 23. [Google Scholar] [CrossRef]

- Oliveira, V.; Lopes, P.; Cabral, M.; Pereira, H. Kinetics of oxygen ingress into wine bottles closed with natural cork stoppers of different qualities. Am. J. Enol. Vitic. 2013, 64, 395–399. [Google Scholar] [CrossRef]

- Goode, J. Alternatives to Cork in Wine Bottle Closures; Woodhead Publishing Limited: Cambridge, UK, 2010. [Google Scholar]

- Lequin, S.; Chassagne, D.; Karbowiak, T.; Simon, J.M.; Paulin, C.; Bellat, J.P. Diffusion of oxygen in cork. J. Agric. Food Chem. 2012, 60, 3348–3356. [Google Scholar] [CrossRef]

- Lagorce-Tachon, A.; Karbowiak, T.; Paulin, C.; Simon, J.M.; Gougeon, R.D.; Bellat, J.P. About the Role of the Bottleneck/Cork Interface on Oxygen Transfer. J. Agric. Food Chem. 2016, 64, 6672–6675. [Google Scholar] [CrossRef] [Green Version]

- Coelho, C.; Julien, P.; Nikolantonaki, M.; Noret, L.; Magne, M.; Ballester, J.; Gougeon, R.D. Molecular and Macromolecular Changes in Bottle-Aged White Wines Reflect Oxidative Evolution–Impact of Must Clarification and Bottle Closure. Front. Chem. 2018, 6, 95. [Google Scholar] [CrossRef]

- He, J.; Zhou, Q.; Peck, J.; Soles, R.; Qian, M.C. The effect of wine closures on volatile sulfur and other compounds during post-bottle ageing. Flavour Fragr. J. 2013, 28, 118–128. [Google Scholar] [CrossRef]

- Crouvisier-Urion, K.; Bellat, J.P.; Gougeon, R.D.; Karbowiak, T. Gas transfer through wine closures: A critical review. Trends Food Sci. Technol. 2018, 78, 255–269. [Google Scholar] [CrossRef]

- Lambri, M.; Silva, A.; De Faveri, D.M. Relationship between the inner cellulation of synthetic stoppers and the browning of a white wine over eighteen months of storage. Ital. J. Food Sci. 2012, 24, 149–158. [Google Scholar]

- Rives, J.; Fernández-Rodríguez, I.; Rieradevall, J.; Gabarrell, X. Environmental analysis of the production of champagne cork stoppers. J. Clean. Prod. 2012, 25, 1–13. [Google Scholar] [CrossRef]

- Fonseca, A.L.; Brazinha, C.; Pereira, H.; Crespo, J.G.; Teodoro, O.M.N.D. Permeability of cork for water and ethanol. J. Agric. Food Chem. 2013, 61, 9672–9679. [Google Scholar] [CrossRef]

- Han, G.; Ugliano, M.; Currie, B.; Vidal, S.; Diéval, J.B.; Waterhouse, A.L. Influence of closure, phenolic levels and microoxygenation on Cabernet Sauvignon wine composition after 5 years’ bottle storage. J. Sci. Food Agric. 2015, 95, 36–43. [Google Scholar] [CrossRef]

- Chanut, J.; Bellat, J.-P.; Gougeon, R.D.; Karbowiak, T. Controlled diffusion by thin layer coating: The intricate case of the glass-stopper interface. Food Control 2021, 120, 107446. [Google Scholar] [CrossRef]

- Hopfer, H.; Ebeler, S.E.; Heymann, H. The combined effects of storage temperature and packaging type on the sensory and chemical properties of chardonnay. J. Agric. Food Chem. 2012, 60, 10743–10754. [Google Scholar] [CrossRef]

- Lopes, P.; Saucier, C.; Glories, Y. Nondestructive colorimetric method to determine the oxygen diffusion rate through closures used in winemaking. J. Agric. Food Chem. 2005, 53, 6967–6973. [Google Scholar] [CrossRef]

- Lopes, P.; Saucier, C.; Teissedre, P.L.; Glories, Y. Impact of storage position on oxygen ingress through different closures into wine bottles. J. Agric. Food Chem. 2006, 54, 6741–6746. [Google Scholar] [CrossRef] [PubMed]

- Lopes, P.; Silva, M.A.; Pons, A.; Tominaga, T.; Lavigne, V.; Saucier, C.; Darriet, P.; Teissedre, P.-L.; Dubourdieu, D. Impact of Oxygen Dissolved at Bottling and Transmitted through Closures on the Composition and Sensory Properties of a Sauvignon Blanc Wine during Bottle Storage. J. Agric. Food Chem. 2009, 57, 10261–10270. [Google Scholar] [CrossRef] [PubMed]

- Kanavouras, A.; Coutelieris, F.; Karanika, E.; Kotseridis, Y.; Kallithraka, S. Colour change of bottled white wines as a quality indicator. OENO One 2020, 54, 543–551. [Google Scholar] [CrossRef]

- Oliveira, V.; Lopes, P.; Cabral, M.; Pereira, H. Influence of cork defects in the oxygen ingress through wine stoppers: Insights with X-ray tomography. J. Food Eng. 2015, 165, 66–73. [Google Scholar] [CrossRef]

- Baiano, A.; De Gianni, A. A study on the effects of oxygen transmission rate of synthetic stopper on wine quality: The case of Nero di Troia. Eur. Food Res. Technol. 2016, 242, 1857–1867. [Google Scholar] [CrossRef]

- Waterhouse, A.L.; Sacks, G.L.; Jeffery, D.W. Topics Related to Aging. In Understanding Wine Chemistry; John Wiley & Sons, Ltd.: Chichester, UK, 2016; pp. 294–317. [Google Scholar]

- Keenan, C.P.; Gözükara, M.Y.; Christie, G.B.Y.; Heyes, D.N. Oxygen permeability of macrocrystalline paraffin wax and relevance to wax coatings on natural corks used as wine bottle closures. Aust. J. Grape Wine Res. 1999, 5, 66–70. [Google Scholar] [CrossRef]

- Tarasov, A.; Rauhut, D.; Jung, R. Bottle capsules as a barrier against airborne 2,4,6-trichloroanisole. Food Chem. 2018, 268, 463–467. [Google Scholar] [CrossRef]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Xiaoguo, Y.; Quartacci, M.F.; Sgherri, C.; Andrich, G.; Zinnai, A. A kinetic approach to describe the time evolution of red wine as a function of packaging conditions adopted: Influence of closure and storage position. Food Packag. Shelf Life 2017, 13, 44–48. [Google Scholar] [CrossRef]

- Lagorce-Tachon, A.; Karbowiak, T.; Champion, D.; Gougeon, R.D.; Bellat, J.P. Mechanical properties of cork: Effect of hydration. Mater. Des. 2015, 82, 148–154. [Google Scholar] [CrossRef]

- Silva, A.; Lambri, M.; De Faveri, M.D. Evaluation of the performances of synthetic and cork stoppers up to 24 months post-bottling. Eur. Food Res. Technol. 2003, 216, 529–534. [Google Scholar] [CrossRef]

- Grainger, K.; Tattersall, H. Preparing wine for bottling. Wine Prod. Qual. 2016, 116–125. [Google Scholar] [CrossRef]

- Barber, N.; Taylor, D.C.; Dodd, T. The importance of wine bottle closures in retail purchase decisions of consumers. J. Hosp. Leis. Mark. 2009, 18, 597–614. [Google Scholar] [CrossRef]

- Grainger, K. Wine Faults and Flaws. Wine Qual. 2009, 67–77. [Google Scholar] [CrossRef]

- Danilewicz, J.C. Mechanism of Autoxidation of Polyphenols and Participation of Sulfite in Wine: Key Role of Iron. Am. J. Enol. Vitic. 2011, 62, 319–328. [Google Scholar] [CrossRef]

- Viviers, M.Z.; Smith, M.E.; Wilkes, E.; Smith, P. Effects of five metals on the evolution of hydrogen sulfide, methanethiol, and dimethyl sulfide during anaerobic storage of chardonnay and shiraz wines. J. Agric. Food Chem. 2013, 61, 12385–12396. [Google Scholar] [CrossRef]

- Vela, E.; Hernández-Orte, P.; Franco-Luesma, E.; Ferreira, V. The effects of copper fining on the wine content in sulfur off-odors and on their evolution during accelerated anoxic storage. Food Chem. 2017, 231, 212–221. [Google Scholar] [CrossRef] [Green Version]

- Danilewicz, J.C.; Wallbridge, P.J. Further studies on the mechanism of interaction of polyphenols, oxygen, and sulfte in wine. Am. J. Enol. Vitic. 2010, 61, 166–175. [Google Scholar]

- Danilewicz, J.C. Interaction of sulfur dioxide, polyphenols, and oxygen in a wine-model system: Central role of iron and copper. Am. J. Enol. Vitic. 2007, 58, 53–60. [Google Scholar]

- Lissi, E.; Campos, A.M.; Calderón, C.; Lobato, S.; López-Alarcón, C. Effects of Aging on the Antioxidant Capacity of Red Wines; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9780124047389. [Google Scholar]

- Monagas, M.; Bartolomé, B.; Gómez-Cordovés, C. Evolution of polyphenols in red wines from Vitis vinifera L. during aging in the bottle: IIII. Non-anthocyanin phenolic compounds. Eur. Food Res. Technol. 2005, 220, 331–340. [Google Scholar] [CrossRef]

- Waterhouse, A.L.; Laurie, V.F. Oxidation of Wine Phenolics: A Critical Evaluation and Hypotheses. Am. J. Enol. Vitic. 2006, 57, 306–313. [Google Scholar]

- Nikolantonaki, M.; Magiatis, P.; Waterhouse, A.L. Measuring protection of aromatic wine thiols from oxidation by competitive reactions vs wine preservatives with ortho-quinones. Food Chem. 2014, 163, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Makhotkina, O.; Kilmartin, P.A. Uncovering the influence of antioxidants on polyphenol oxidation in wines using an electrochemical method: Cyclic voltammetry. J. Electroanal. Chem. 2009, 633, 165–174. [Google Scholar] [CrossRef]

- Oliveira, C.M.; Santos, S.A.O.; Silvestre, A.J.D.; Barros, A.S.; Ferreira, A.C.S.; Silva, A.M.S. Quinones as Strecker degradation reagents in wine oxidation processes. Food Chem. 2017, 228, 618–624. [Google Scholar] [CrossRef]

- Bradshaw, M.P.; Barril, C.; Clark, A.C.; Prenzler, P.D.; Scollary, G.R. Ascorbic acid: A review of its chemistry and reactivity in relation to a wine environment. Crit. Rev. Food Sci. Nutr. 2011, 51, 479–498. [Google Scholar] [CrossRef] [PubMed]

- Kontoudakis, N.; Clark, A.C. Sulfide-binding to Cu(II) in wine: Impact on oxygen consumption rates. Food Chem. 2020, 316, 126352. [Google Scholar] [CrossRef] [PubMed]

- Ugliano, M. Oxygen Contribution to Wine Aroma Evolution during Bottle Aging. J. Agric. Food Chem. 2013, 61, 6125–6136. [Google Scholar] [CrossRef] [PubMed]

- Grant-Preece, P.; Barril, C.; Schmidtke, L.M.; Scollary, G.R.; Clark, A.C. Light-induced changes in bottled white wine and underlying photochemical mechanisms. Crit. Rev. Food Sci. Nutr. 2017, 57, 743–754. [Google Scholar] [CrossRef] [PubMed]

- International Organisation of Vine and Wine (OIV). Compendium of International Methods of Wine and Must Analysis; International Organisation of Vine and Wine (OIV): Paris, France, 2020; Volume 1, ISBN 978-2-85038-016-7.

- Danilewicz, J.C.; Standing, M.J. Reaction mechanisms of oxygen and sulfite in red wine. Am. J. Enol. Vitic. 2018, 69, 189–195. [Google Scholar] [CrossRef]

- Carrascón, V.; Vallverdú-Queralt, A.; Meudec, E.; Sommerer, N.; Fernandez-Zurbano, P.; Ferreira, V. The kinetics of oxygen and SO2 consumption by red wines. What do they tell about oxidation mechanisms and about changes in wine composition? Food Chem. 2018, 241, 206–214. [Google Scholar] [CrossRef] [Green Version]

- Waterhouse, A.L.; Frost, S.; Ugliano, M.; Cantu, A.R.; Currie, B.L.; Anderson, M.; Chassy, A.W.; Vidal, S.; Dieval, J.-B.; Aagaard, O.; et al. Sulfur Dioxide-Oxygen Consumption Ratio Reveals Differences in Bottled Wine Oxidation. Am. J. Enol. Vitic. 2016, 67, 449–459. [Google Scholar] [CrossRef]

- Smith, P.A.; Mcrae, J.M.; Bindon, K.A. Impact of winemaking practices on the concentration and composition of tannins in red wine. Aust. J. Grape Wine Res. 2015, 21, 601–614. [Google Scholar] [CrossRef]

- Gómez, M.E.; Igartuburu, J.M.; Pando, E.; Rodríguez Luis, F.; Mourente, G. Lipid composition of lees from Sherry wine. J. Agric. Food Chem. 2004, 52, 4791–4794. [Google Scholar] [CrossRef] [PubMed]

- Barril, C.; Clark, A.C.; Scollary, G.R. Chemistry of ascorbic acid and sulfur dioxide as an antioxidant system relevant to white wine. Anal. Chim. Acta 2012, 732, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Barril, C.; Rutledge, D.N.; Scollary, G.R.; Clark, A.C. Ascorbic acid and white wine production: A review of beneficial versus detrimental impacts. Aust. J. Grape Wine Res. 2016, 22, 169–181. [Google Scholar] [CrossRef] [Green Version]

- Skouroumounis, G.K.; Kwiatkowski, M.J.; Francis, I.L.; Oakey, H.; Capone, D.L.; Peng, Z.; Duncan, B.; Sefton, M.A.; Waters, E.J. The influence of ascorbic acid on the composition, colour and flavour properties of a Riesling and a wooded Chardonnay wine during five years’ storage. Aust. J. Grape Wine Res. 2005, 11, 355–368. [Google Scholar] [CrossRef]

- Barril, C.; Clark, A.C.; Prenzler, P.D.; Karuso, P.; Scollary, G.R. Formation of pigment precursor (+)-1″-methylene-6″-hydroxy2H-furan-5″-one-catechin isomers from (+)-catechin and a degradation product of ascorbic acid in a model wine system. J. Agric. Food Chem. 2009, 57, 9539–9546. [Google Scholar] [CrossRef]

- Es-Safi, N.E.; Le Guernevé, C.; Fulcrand, H.; Cheynier, V.; Moutounet, M. New polyphenolic compounds with xanthylium skeletons formed through reaction between (+)-catechin and glyoxylic acid. J. Agric. Food Chem. 1999, 47, 5211–5217. [Google Scholar] [CrossRef]

- Arapitsas, P.; Ugliano, M.; Perenzoni, D.; Angeli, A.; Pangrazzi, P.; Mattivi, F. Wine metabolomics reveals new sulfonated products in bottled white wines, promoted by small amounts of oxygen. J. Chromatogr. A 2016, 1429, 155–165. [Google Scholar] [CrossRef]

- Danilewicz, J.C. Role of tartaric and malic acids in wine oxidation. J. Agric. Food Chem. 2014, 62, 5149–5155. [Google Scholar] [CrossRef]

- Bührle, F.; Gohl, A.; Weber, F. Impact of Xanthylium Derivatives on the Color of White Wine. Molecules 2017, 22, 1376. [Google Scholar] [CrossRef] [Green Version]

- Waterhouse, A.L.; Zhu, J. A quarter century of wine pigment discovery. J. Sci. Food Agric. 2020, 100, 5093–5101. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.; Mateus, N.; Silva, A.M.S.; De Freitas, V. Equilibrium forms of vitisin B pigments in an aqueous system studied by NMR and visible spectroscopy. J. Phys. Chem. B 2009, 113, 11352–11358. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, M.; Jerz, G.; Winterhalter, P. Isolation and structure of Pinotin A, a new anthocyanin derivative from Pinotage wine. Vitis 2003, 42, 105–106. [Google Scholar]

- Mateus, N.; Oliveira, J.; Haettich-Motta, M.; De Freitas, V. New family of bluish pyranoanthocyanins. J. Biomed. Biotechnol. 2004, 2004, 299–305. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, J.; Santos-Buelga, C.; Silva, A.M.S.; De Freitas, V.; Mateus, N. Chromatic and structural features of blue anthocyanin-derived pigments present in Port wine. Anal. Chim. Acta 2006, 563, 2–9. [Google Scholar] [CrossRef]

- Alcalde-Eon, C.; Escribano-Bailón, M.T.; Santos-Buelga, C.; Rivas-Gonzalo, J.C. Identification of dimeric anthocyanins and new oligomeric pigments in red wine by means of HPLC-DAD-ESI/MSn. J. Mass Spectrom. 2007, 42, 735–748. [Google Scholar] [CrossRef]

- Cruz, L.; Teixeira, N.; Silva, A.M.S.; Mateus, N.; Borges, J.; De Freitas, V. Role of vinylcatechin in the formation of pyranomalvidin-3-glucoside-(+)-catechin. J. Agric. Food Chem. 2008, 56, 10980–10987. [Google Scholar] [CrossRef]

- De Freitas, V.; Mateus, N. Formation of pyranoanthocyanins in red wines: A new and diverse class of anthocyanin derivatives. Anal. Bioanal. Chem. 2011, 401, 1467–1477. [Google Scholar] [CrossRef]

- Oliveira, J.; Azevedo, J.; Silva, A.M.S.; Teixeira, N.; Cruz, L.; Mateus, N.; De Freitas, V. Pyranoanthocyanin dimers: A new family of turquoise blue anthocyanin-derived pigments found in port wine. J. Agric. Food Chem. 2010, 58, 5154–5159. [Google Scholar] [CrossRef]

- He, J.; Oliveira, J.; Silva, A.M.S.; Mateus, N.; De Freitas, V. Oxovitisins: A new class of neutral pyranone-anthocyanin derivatives in red wines. J. Agric. Food Chem. 2010, 58, 8814–8819. [Google Scholar] [CrossRef]

- Sánchez-Ilárduya, M.B.; Sánchez-Fernández, C.; Viloria-Bernal, M.; López-Márquez, D.M.; Berrueta, L.A.; Gallo, B.; Vicente, F. Mass spectrometry fragmentation pattern of coloured flavanol-anthocyanin and anthocyanin-flavanol derivatives in aged red wines of Rioja. Aust. J. Grape Wine Res. 2012, 18, 203–214. [Google Scholar] [CrossRef]

- Bueno, M.; Marrufo-Curtido, A.; Carrascón, V.; Fernández-Zurbano, P.; Escudero, A.; Ferreira, V. Formation and Accumulation of Acetaldehyde and Strecker Aldehydes during Red Wine Oxidation. Front. Chem. 2018, 6. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Jin, G.J.; Wang, X.J.; Kong, C.L.; Liu, J.; Tao, Y.S. Chemical profiles and aroma contribution of terpene compounds in Meili (Vitis vinifera L.) grape and wine. Food Chem. 2019, 284, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Waterhouse, A.L.; Sacks, G.L.; Jeffery, D.W. Understanding Wine Chemistry. Underst. Wine Chem. 2016, 11–14. [Google Scholar] [CrossRef]

- Capone, D.L.; Van Leeuwen, K.; Taylor, D.K.; Jeffery, D.W.; Pardon, K.H.; Elsey, G.M.; Sefton, M.A. Evolution and occurrence of 1,8-cineole (Eucalyptol) in Australian wine. J. Agric. Food Chem. 2011, 59, 953–959. [Google Scholar] [CrossRef] [PubMed]

- Sefton, M.A.; Skouroumounis, G.K.; Elsey, G.M.; Taylor, D.K. Occurrence, sensory impact, formation, and fate of damascenone in grapes, wines, and other foods and beverages. J. Agric. Food Chem. 2011, 59, 9717–9746. [Google Scholar] [CrossRef]

- Collin, S.; Nizet, S.; Claeys Bouuaert, T.; Despatures, P.M. Main odorants in Jura flor-sherry wines. Relative contributions of sotolon, abhexon, and theaspirane-derived compounds. J. Agric. Food Chem. 2012, 60, 380–387. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Hermosín-Gutiérrez, I.; Pérez-Coello, M.S. Accelerated Aging against Conventional Storage: Effects on the Volatile Composition of Chardonnay White Wines. J. Food Sci. 2013, 78, C507–C513. [Google Scholar] [CrossRef]

- Pons, A.; Lavigne, V.; Landais, Y.; Darriet, P.; Dubourdieu, D. Identification of a sotolon pathway in dry white wines. J. Agric. Food Chem. 2010, 58, 7273–7279. [Google Scholar] [CrossRef]

- Tominaga, T.; Guimbertau, G.; Dubourdieu, D. Role of certain volatile thiols in the bouquet of aged Champagne wines. J. Agric. Food Chem. 2003, 51, 1016–1020. [Google Scholar] [CrossRef]

- Moreno-Arribas, M.V.; Polo, M.C. Wine chemistry and biochemistry. Wine Chem. Biochem. 2009, 1–735. [Google Scholar] [CrossRef]

- Tominaga, T.; Guimbertau, G.; Dubourdieu, D. Contribution of benzenemethanethiol to smoky aroma of certain Vitis vinifera L. wines. J. Agric. Food Chem. 2003, 51, 1373–1376. [Google Scholar] [CrossRef] [PubMed]

- Fulcrand, H.; Benabdeljalil, C.; Rigaud, J.; Cheynier, V.; Moutounet, M. A new class of wine pigments generated by reaction between pyruvic acid and grape anthocyanins. Phytochemistry 1998, 47, 1401–1407. [Google Scholar] [CrossRef]

- Mateus, N.; Silva, A.M.S.; Santos-Buelga, C.; Rivas-Gonzalo, J.C.; De Freitas, V. Identification of anthocyanin-flavanol pigments in red wines by NMR and mass spectrometry. J. Agric. Food Chem. 2002, 50, 2110–2116. [Google Scholar] [CrossRef]

- Oliveira, J.; de Freitas, V.; Silva, A.M.S.; Mateus, N. Reaction between Hydroxycinnamic Acids and Anthocyanin−Pyruvic Acid Adducts Yielding New Portisins. J. Agric. Food Chem. 2007, 55, 6349–6356. [Google Scholar] [CrossRef]

- He, F.; Liang, N.-N.; Mu, L.; Pan, Q.-H.; Wang, J.; Reeves, M.J.; Duan, C.-Q. Anthocyanins and Their Variation in Red Wines II. Anthocyanin Derived Pigments and Their Color Evolution. Molecules 2012, 17, 1483–1519. [Google Scholar] [CrossRef] [Green Version]

- Bakker, J.; Timberlake, C.F. Isolation, Identification, and Characterization of New Color-Stable Anthocyanins Occurring in Some Red Wines. J. Agric. Food Chem. 1997, 45, 35–43. [Google Scholar] [CrossRef]

- Oliveira, J.; de Freitas, V.; Mateus, N. Polymeric Pigments in Red Wines. Red Wine Technol. 2018, 207–218. [Google Scholar] [CrossRef]

- Nave, F.; Teixeira, N.; Mateus, N.; de Freitas, V. The fate of flavanol-anthocyanin adducts in wines: Study of their putative reaction patterns in the presence of acetaldehyde. Food Chem. 2010, 121, 1129–1138. [Google Scholar] [CrossRef]

- Vallverdú-Queralt, A.; Meudec, E.; Eder, M.; Lamuela-Raventos, R.M.; Sommerer, N.; Cheynier, V. The Hidden Face of Wine Polyphenol Polymerization Highlighted by High-Resolution Mass Spectrometry. ChemistryOpen 2017, 6, 336–339. [Google Scholar] [CrossRef] [Green Version]

- Es-Safi, N.E.; Le Guernevé, C.; Labarbe, B.; Fulcrand, H.; Cheynier, V.; Moutounet, M. Structure of a new xanthylium salt derivative. Tetrahedron Lett. 1999, 40, 5869–5872. [Google Scholar] [CrossRef]

- Silva, M.A.; Julien, M.; Jourdes, M.; Teissedre, P.-L. Impact of closures on wine post-bottling development: A review. Eur. Food Res. Technol. 2011, 233, 905–914. [Google Scholar] [CrossRef]

- Mayr, C.M.; Capone, D.L.; Pardon, K.H.; Black, C.A.; Pomeroy, D.; Francis, I.L. Quantitative Analysis by GC-MS/MS of 18 Aroma Compounds Related to Oxidative Off-Flavor in Wines. J. Agric. Food Chem. 2015, 63, 3394–3401. [Google Scholar] [CrossRef] [PubMed]

- Rousserie, P.; Rabot, A.; Geny-Denis, L. From Flavanols Biosynthesis to Wine Tannins: What Place for Grape Seeds? J. Agric. Food Chem. 2019, 67, 1325–1343. [Google Scholar] [CrossRef] [PubMed]

- Prieur, C.; Rigaud, J.; Cheynier, V.; Moutounet, M. Oligomeric and polymeric procyanidins from grape seeds. Phytochemistry 1994, 36, 781–784. [Google Scholar] [CrossRef]

- Drinkine, J.; Lopes, P.; Kennedy, J.A.; Teissedre, P.L.; Saucier, C. Ethylidene-bridged flavan-3-ols in red wine and correlation with wine age. J. Agric. Food Chem. 2007, 55, 6292–6299. [Google Scholar] [CrossRef]

- Jourdes, M.; Lefeuvre, D.; Quideau, S. C-glycosidic ellagitannins and their influence on wine chemistry. In Chemistry and Biology of Ellagitannins: An Underestimated Class of Bioactive Plant Polyphenols; Quideau, S., Ed.; World Scientific Publishing: Singapore, 2009; pp. 320–366. ISBN 978-981-279-740-7. [Google Scholar]

- Chira, K.; Jourdes, M.; Teissedre, P.L. Cabernet sauvignon red wine astringency quality control by tannin characterization and polymerization during storage. Eur. Food Res. Technol. 2012, 234, 253–261. [Google Scholar] [CrossRef]

- Sacks, G.L.; Gates, M.J.; Ferry, F.X.; Lavin, E.H.; Kurtz, A.J.; Acree, T.E. Sensory threshold of 1,1,6-trimethyl-1,2-dihydronaphthalene (TDN) and concentrations in young Riesling and non-Riesling wines. J. Agric. Food Chem. 2012, 60, 2998–3004. [Google Scholar] [CrossRef]

- Sáenz-Navajas, M.P.; Avizcuri, J.M.; Ballester, J.; Fernández-Zurbano, P.; Ferreira, V.; Peyron, D.; Valentin, D. Sensory-active compounds influencing wine experts’ and consumers’ perception of red wine intrinsic quality. LWT-Food Sci. Technol. 2015, 60, 400–411. [Google Scholar] [CrossRef]

- Vázquez-Pateiro, I.; Arias-González, U.; Mirás-Avalos, J.M.; Falqué, E. Evolution of the aroma of treixadura wines during bottle aging. Foods 2020, 9, 1419. [Google Scholar] [CrossRef]

- Pedersen, D.S.; Capone, D.L.; Skouroumounis, G.K.; Pollnitz, A.P.; Sefton, M.A. Quantitative analysis of geraniol, nerol, linalool, and α-terpineol in wine. Anal. Bioanal. Chem. 2003, 375, 517–522. [Google Scholar] [CrossRef] [PubMed]

- Roland, A.; Schneider, R.; Razungles, A.; Cavelier, F. Varietal thiols in wine: Discovery, analysis and applications. Chem. Rev. 2011, 111, 7355–7376. [Google Scholar] [CrossRef] [PubMed]

- Lund, C.M.; Thompson, M.K.; Benkwitz, F.; Wohler, M.W.; Triggs, C.M.; Gardner, R.; Heymann, H.; Laura, N. New Zealand Sauvignon blanc Distinct Flavor Characteristics: Sensory, Chemical, and Consumer Aspects. Am. J. Enol. Vitic. 2009, 60, 1–12. [Google Scholar]

- Tominaga, T.; Dubourdieu, D. A novel method for quantification of 2-methyl-3-furanthiol and 2-furanmethanethiol in wines made from Vitis vinifera grape varieties. J. Agric. Food Chem. 2006, 54, 29–33. [Google Scholar] [CrossRef] [PubMed]

- Wrolstad, R.E.; Durst, R.W.; Lee, J. Tracking color and pigment changes in anthocyanin products. Trends Food Sci. Technol. 2005, 16, 423–428. [Google Scholar] [CrossRef]

- Atanasova, V.; Fulcrand, H.; Cheynier, V.; Moutounet, M. Effect of oxygenation on polyphenol changes occurring in the course of wine-making. Anal. Chim. Acta 2002, 458, 15–27. [Google Scholar] [CrossRef]

- Cassino, C.; Tsolakis, C.; Bonello, F.; Gianotti, V.; Osella, D. Wine evolution during bottle aging, studied by 1H NMR spectroscopy and multivariate statistical analysis. Food Res. Int. 2019, 116, 566–577. [Google Scholar] [CrossRef]

- Ristic, R.; Van Der Hulst, L.; Capone, D.L.; Wilkinson, K.L. Impact of Bottle Aging on Smoke-Tainted Wines from Different Grape Cultivars. J. Agric. Food Chem. 2017, 65, 4146–4152. [Google Scholar] [CrossRef]

- del Alamo-Sanza, M.; Nevares, I.; Martínez-Gil, A.; Rubio-Bretón, P.; Garde-Cerdán, T. Impact of long bottle aging (10 years) on volatile composition of red wines micro-oxygenated with oak alternatives. LWT 2019, 101, 395–403. [Google Scholar] [CrossRef]

- Recamales, Á.F.; Sayago, A.; González-Miret, M.L.; Hernanz, D. The effect of time and storage conditions on the phenolic composition and colour of white wine. Food Res. Int. 2006, 39, 220–229. [Google Scholar] [CrossRef]

- Nikolantonaki, M.; Waterhouse, A.L. A method to quantify quinone reaction rates with wine relevant nucleophiles: A key to the understanding of oxidative loss of varietal thiols. J. Agric. Food Chem. 2012, 60, 8484–8491. [Google Scholar] [CrossRef] [PubMed]

- Pati, S.; Crupi, P.; Savastano, M.L.; Benucci, I.; Esti, M. Evolution of phenolic and volatile compounds during bottle storage of a white wine without added sulfite. J. Sci. Food Agric. 2020, 100, 775–784. [Google Scholar] [CrossRef] [PubMed]

- Kallithraka, S.; Salacha, M.I.; Tzourou, I. Changes in phenolic composition and antioxidant activity of white wine during bottle storage: Accelerated browning test versus bottle storage. Food Chem. 2009, 113, 500–505. [Google Scholar] [CrossRef]

- Burin, V.M.; Freitas Costa, L.L.; Rosier, J.P.; Bordignon-Luiz, M.T. Cabernet Sauvignon wines from two different clones, characterization and evolution during bottle ageing. LWT-Food Sci. Technol. 2011, 44, 1931–1938. [Google Scholar] [CrossRef]

- Carrascon, V.; Fernandez-Zurbano, P.; Bueno, M.; Ferreira, V. Oxygen Consumption by Red Wines. Part II: Differential Effects on Color and Chemical Composition Caused by Oxygen Taken in Different Sulfur Dioxide-Related Oxidation Contexts. J. Agric. Food Chem. 2015, 63, 10938–10947. [Google Scholar] [CrossRef] [Green Version]

- Sioumis, N.; Kallithraka, S.; Tsoutsouras, E.; Makris, D.P.; Kefalas, P. Browning development in white wines: Dependence on compositional parameters and impact on antioxidant characteristics. Eur. Food Res. Technol. 2005, 220, 326–330. [Google Scholar] [CrossRef]

- Ferreira, V.; Bueno, M.; Franco-Luesma, E.; Culleré, L.; Fernández-Zurbano, P. Key Changes in Wine Aroma Active Compounds during Bottle Storage of Spanish Red Wines under Different Oxygen Levels. J. Agric. Food Chem. 2014, 62, 10015–10027. [Google Scholar] [CrossRef]

- Scrimgeour, N.; Nordestgaard, S.; Lloyd, N.D.R.; Wilkes, E.N. Exploring the effect of elevated storage temperature on wine composition. Aust. J. Grape Wine Res. 2015, 21, 713–722. [Google Scholar] [CrossRef]

- Hofmann, T.; Schieberle, P.; Grosch, W. Model Studies on the Oxidative Stability of Odor-Active Thiols Occurring in Food Flavors. J. Agric. Food Chem. 1996, 44, 251–255. [Google Scholar] [CrossRef]

- Rigou, P.; Triay, A.; Razungles, A. Influence of volatile thiols in the development of blackcurrant aroma in red wine. Food Chem. 2014, 142, 242–248. [Google Scholar] [CrossRef]

- Smith, M.E.; Bekker, M.Z.; Smith, P.A.; Wilkes, E.N. Sources of volatile sulfur compounds in wine. Aust. J. Grape Wine Res. 2015, 21, 705–712. [Google Scholar] [CrossRef]

- Ferreira, V.; Bueno, M.; Franco-Luesma, E. New insights into the chemistry involved in aroma development during wine bottle aging: Slow redox processes and chemical equilibrium shifts. ACS Symp. Ser. 2015, 1203, 275–289. [Google Scholar] [CrossRef]

- Kreitman, G.Y.; Danilewicz, J.C.; Jeffery, D.D.W.; Elias, R.J. Copper(II)-mediated hydrogen sulfide and thiol oxidation to disulfides and organic polysulfanes and their reductive cleavage in wine: Mechanistic elucidation and potential applications. J. Agric. Food Chem. 2017, 65, 2564–2571. [Google Scholar] [CrossRef] [PubMed]

- Rousseva, M.; Kontoudakis, N.; Schmidtke, L.M.; Scollary, G.R.; Clark, A.C. Impact of wine production on the fractionation of copper and iron in Chardonnay wine: Implications for oxygen consumption. Food Chem. 2016, 203, 440–447. [Google Scholar] [CrossRef]

- Ferreira, V.; Franco-Luesma, E.; Vela, E.; López, R.; Hernández-Orte, P. Elusive Chemistry of Hydrogen Sulfide and Mercaptans in Wine. J. Agric. Food Chem. 2018, 66, 2237–2246. [Google Scholar] [CrossRef] [PubMed]

- Franco-Luesma, E.; Ferreira, V. Reductive off-odors in wines: Formation and release of H2S and methanethiol during the accelerated anoxic storage of wines. Food Chem. 2016, 199, 42–50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vela, E.; Hernandez-Orte, P.; Franco-Luesma, E.; Ferreira, V. Micro-oxygenation does not eliminate hydrogen sulfide and mercaptans from wine; it simply shifts redox and complex-related equilibria to reversible oxidized species and complexed forms. Food Chem. 2018, 243, 222–230. [Google Scholar] [CrossRef]

- Bekker, M.Z.; Smith, M.E.; Smith, P.A.; Wilkes, E.N. Formation of hydrogen sulfide in wine: Interactions between copper and sulfur dioxide. Molecules 2016, 21, 1214. [Google Scholar] [CrossRef] [Green Version]

- Pripi-Nicolau, L.; De Revel, G.; Bertrand, A.; Maujean, A. Formation of flavor components by the reaction of amino acid and carbonyl compounds in mild conditions. J. Agric. Food Chem. 2000, 48, 3761–3766. [Google Scholar] [CrossRef]

- Pereira, B.; Lopes, P.; Marques, J.; Pimenta, M.; Alves, C.; Roseira, I.; Mendes, A.; Cabral, M. Sealing effectiveness of different types of closures towards volatile phenols and haloanisoles. OENO One 2013, 47, 145–157. [Google Scholar] [CrossRef]

- Falconer, R.J.; Marangon, M.; Van Sluyter, S.C.; Neilson, K.A.; Chan, C.; Waters, E.J. Thermal stability of thaumatin-like protein, chitinase, and invertse isolated from sauvignon blanc and semillon juice and their role in haze formation in wine. J. Agric. Food Chem. 2010, 58, 975–980. [Google Scholar] [CrossRef] [PubMed]

- Clark, A.C.; Wilkes, E.N.; Scollary, G.R. Chemistry of copper in white wine: A review. Aust. J. Grape Wine Res. 2015, 21, 339–350. [Google Scholar] [CrossRef]

- Robinson, A.L.; Mueller, M.; Heymann, H.; Ebeler, S.E.; Boss, P.K.; Solomon, P.S.; Trengove, R.D. Effect of simulated shipping conditions on sensory attributes and volatile composition of commercial white and red wines. Am. J. Enol. Vitic. 2010, 61, 337–347. [Google Scholar]

- Clark, A.C.; Dias, D.A.; Smith, T.A.; Ghiggino, K.P.; Scollary, G.R. Iron(III) tartrate as a potential precursor of light-induced oxidative degradation of white wine: Studies in a model wine system. J. Agric. Food Chem. 2011, 59, 3575–3581. [Google Scholar] [CrossRef]

- Maury, C.; Clark, A.C.; Scollary, G.R. Determination of the impact of bottle colour and phenolic concentration on pigment development in white wine stored under external conditions. Anal. Chim. Acta 2010, 660, 81–86. [Google Scholar] [CrossRef]

- Ferreira-Lima, N.E.; Burin, V.M.; Bordignon-Luiz, M.T. Characterization of Goethe white wines: Influence of different storage conditions on the wine evolution during bottle aging. Eur. Food Res. Technol. 2013, 237, 509–520. [Google Scholar] [CrossRef]

- Ocón, E.; Gutiérrez, A.R.; Garijo, P.; Santamaría, P.; López, R.; Olarte, C.; Sanz, S. Influence of winery age and design on the distribution of airborne molds in three Rioja wine cellars. Am. J. Enol. Vitic. 2014, 65, 479–485. [Google Scholar] [CrossRef] [Green Version]

- Mas, A.; Puig, J.; Lladoa, N.; Zamora, F. Sealing and storage position effects on wine evolution. J. Food Sci. 2002, 67, 1374–1378. [Google Scholar] [CrossRef]

- Hernanz, D.; Gallo, V.; Recamales, Á.F.; Meléndez-Martínez, A.J.; González-Miret, M.L.; Heredia, F.J. Effect of storage on the phenolic content, volatile composition and colour of white wines from the varieties Zalema and Colombard. Food Chem. 2009, 113, 530–537. [Google Scholar] [CrossRef]

- Cravero, M.C. Musty and moldy taint in wines: A review. Beverages 2020, 6, 41. [Google Scholar] [CrossRef]

- Prescott, J.; Norris, L.; Kunst, M.; Kim, S. Estimating a “consumer rejection threshold” for cork taint in white wine. Food Qual. Prefer. 2005, 16, 345–349. [Google Scholar] [CrossRef]

- Oliveira, V.; Pereira, H. Cork and Cork Stoppers: Quality and Performance. In Winemaking-Stabilization, Aging Chemistry and Biochemistry; IntechOpen: London, UK, 2020. [Google Scholar]

| Type | Size Range (Length × Diameter) (mm) | Oxygen Transfer Rate (mg/Year) ** | References |

|---|---|---|---|

| Natural cork | 49 × 24 | 5.5 | [28] |

| 45 × 24 | 6.37 | [45] | |

| 44.7 × 24 | 2.03 | [46] | |

| 45 × 24 | 14.25 | [34] | |

| 45 × 24 | 3.65 | [37] | |

| Agglomerated cork | 45 × 24 | 2.62 | [45] |

| 45 × 24 | 1.8 | [47] | |

| Not mentioned | 0.78 | [48] | |

| 45 × 24 | 1.68 | [49] | |

| 45 × 24 | 2.68 | [49] | |

| Technical stopper | 43.6 × 23.7 | 2.03 | [46] |

| 44 × 24 | 1.8 | [29] | |

| 44 × 24 | 1.9 | [47] | |

| 49 × 24.2 | 0.61 | [43] | |

| 49 × 24.2 | 0.38 | [43] | |

| Molded Synthetic | 44.6 × 21 | 6.8 | [46] |

| 44.7 × 21 | 20.8 | [45] | |

| 43 × 22 | 6.5 | [47] | |

| Not mentioned | 22.25 | [42] | |

| Not mentioned | 6.95 | [42] | |

| Extruded synthetic | 43 × 22 | 13.65 | [45] |

| 23 × 38 | 3.28 | [50] | |

| 23 × 38 | 6.57 | [50] | |

| 38 × 24 | 9.38 | [37] | |

| 38 (length) | 4.34 | [25] | |

| Screw cap | 31.5 (diameter) | 2.52 | [29] |

| 31.5 (diameter) | 1.82 | [29] | |

| Not mentioned | 0.23 | [46] | |

| 60 × 30 | 0.5 | [47] | |

| Not mentioned | 0.31 | [37] |

| Type | Name | Pathway(s) | Features | References |

|---|---|---|---|---|

| Pigments | Vitisin A | Condensation with pyruvic acid | Bright red-orange color, stable | [89] |

| Vitisin B | Condensation with acetaldehyde | Bright red-orange color, stable | [90] | |

| Pinotin A-like pyranoanthocyanins | Binding with hydroxycinnamic acids and aldehydes | Red-orange color, stable | [91] | |

| Portisin A, portisin B, portisin C | Binding with flavanols through vinylphenols | Bluish color, stable | [92,93] | |

| Anthocyanin dimers and trimers | Polymerization | Dark-red color, stable | [94] | |

| Anthocyanin-flavanyl adducts | Binding with vinylflavanols | Bright red-orange color, stable | [95] | |

| Anthocyanin-alkyl-flavanol adducts | Binding with an alkylflavanol through aldehydes | Purple color | [96] | |

| Pyranoanthocyanin polymers | Binding of vitisin A with a methyl-pyranoanthocyanin | Light-blue/turquoise color, stable | [97] | |

| Oxovitisins | Hydrolization of Vitisin A | Bright yellow color, stable | [98] | |

| Aldehydes | Acetaldehyde | Ethanol oxidation | Precursor of polymerized pigments and tannins, fruity flavor at low levels, main oxidation marker | [99] |

| Phenylacetaldehyde | Strecker degradation of phenylalanine | Sweet, honey-like aroma at low ct.; mossy aroma at high ct. | [100] | |

| Terpenols | Geraniol | Hydrolysis from linalool | Floral aroma | [101] |

| Linalool | Hydrolysis from geraniol | Rose aroma | [102] | |

| α-terpineol | Hydrolysis from geraniol/linalool | Floral aroma | [103] | |

| Norisoprenoids | β-damascenone | Oxidative cleavage of neoxanthin/allene terpene | Rose aroma, can enhance perception of other fruity aromas | [104] |

| β-ionone | Oxidative cleavage of β-carotene | Cooked apple aroma | [105] | |

| TDN | Decarboxylation with acetaldehyde | Kerosene-like aroma | [106] | |

| Furans | Sotolon | Degradation of ascorbic acid/α-ketobutyric acid | Curry, spicy flavor | [107] |

| Thiols | 2-furanmethanethiol | Proposed formation from furfural | Toasted coffee aroma | [108,109] |

| Benzenemethanethiol | Sulphuration of benzaldehyde | Flint, roast aroma | [110] |

| Compounds. | Increase | Decrease | Ref. | |

|---|---|---|---|---|

| Pigments | Monomeric anthocyanins | * | [134] | |

| Polymeric anthocyanins | * | [114] | ||

| Pyranoanthocyanins | * | [134,135] | ||

| Anthocyanin-flavanol polymers | * | [135] | ||

| Anthocyanin-alkyl adducts | * | [134] | ||

| Volatile phenolics | Guaiacol | * | [136] | |

| Syringol | * | [137] | ||

| Eugenol | * | [138] | ||

| Flavonoids | (+)-catechin | * | [136,139] | |

| (−)-epicathechin | * | [66,136] | ||

| Kaempferol | * | [66,136] | ||

| Thiols | Varietal thiols (3SH, 4MSP, etc.) | * | [140] | |

| Complex thiols (2FMT, BMT, etc.) | * | [108] | ||

| Phenolic acids | Caffeic acid | * | [141,142] | |

| Gallic acid | * | [141,142] | ||

| p-coumaric acid | * | [143] | ||

| Hydroxycinnamic acids | * | [66] | ||

| Syringic acid | * | [136] | ||

| Caftaric acid | * | [139,142] | ||

| Coutaric acid | * | [143] | ||

| Fertaric acid | * | [142] | ||

| Ferulic acid | * | [139] | ||

| Esters | Ethyl acetate | * | [136] | |

| Acetoine | * | [129] | ||

| Terpenols1 | Linalool | * | [144] | |

| Geraniol | * | [101] | ||

| α-terpineol | * | [130] | ||

| Aldehydes | Acetaldehyde | * | [136] | |

| Methional | * | [70] | ||

| Phenylacetaldehyde | * | [121] | ||

| Octanal | * | [42] | ||

| 2-nonanal | * | [42] | ||

| Decanal | * | [31] | ||

| Furfural | * | [121] | ||

| Norisoprenoids | β-damascenone | * | [104] | |

| β-ionone | * | [37] | ||

| TDN | * | [106] | ||

| Tannins | Monomeric flavan-3-ols | * | [126] | |

| Epigallocatehcin | * | [126,144] | ||

| Gallocatechin | * | [144] | ||

| Vescalagin | * | [125] | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echave, J.; Barral, M.; Fraga-Corral, M.; Prieto, M.A.; Simal-Gandara, J. Bottle Aging and Storage of Wines: A Review. Molecules 2021, 26, 713. https://doi.org/10.3390/molecules26030713

Echave J, Barral M, Fraga-Corral M, Prieto MA, Simal-Gandara J. Bottle Aging and Storage of Wines: A Review. Molecules. 2021; 26(3):713. https://doi.org/10.3390/molecules26030713

Chicago/Turabian StyleEchave, Javier, Marta Barral, Maria Fraga-Corral, Miguel A. Prieto, and Jesus Simal-Gandara. 2021. "Bottle Aging and Storage of Wines: A Review" Molecules 26, no. 3: 713. https://doi.org/10.3390/molecules26030713