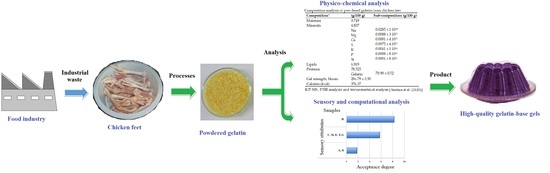

Combination of Computational Techniques to Obtain High-Quality Gelatin-Base Gels from Chicken Feet

Abstract

:1. Introduction

1.1. Poultry Production in Brazil

1.2. Gelatin as a Solution for the Poultry Industry Waste

1.3. Application of Algorithms in Sampling

2. Material and Methods

2.1. Preparation of Gelatines

2.2. Experimental Design

2.3. Sensory Analyses

2.4. Determination of Chemical Properties

2.4.1. Percentage Composition

2.4.2. Spectroscopic Analyses

2.5. Gelatin-Base Gel Classification by Self-Organisation Maps

3. Results and Discussion

3.1. Gelatin Composition

3.2. Classification of Sensorial Attributes

3.3. Optimisation of the Gelatin Production

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AviNews. Statistics and Prices. Available online: https://avicultura.info/pt-br/carne-de-frango-producao-exportacao-2020/ (accessed on 25 March 2021).

- Almeida, P.F.; Araújo, M.G.O.; Santana, J.C.C. Collagen extraction from chicken feet for jelly production. Acta Scientiarum. Technol. 2012, 34, 345–351. [Google Scholar] [CrossRef] [Green Version]

- Lopes, I.R.V.; Zapata, J.F.F.; Freitas, E.R.; Souza, D.V.; Viana Neto, J.L.; Lima, J.R. Meat quality and color of abdominal fat of broilers fed diets containing cashew nut meal treated with antioxidant. Acta Sci. Technol. 2013, 35, 163–174. [Google Scholar] [CrossRef] [Green Version]

- Santana, J.C.C.; Gardim, R.B.; Almeida, P.F.; Borini, G.B.; Quispe, A.P.B.; Llanos, S.A.V.; Heredia, J.A.; Zamuner, S.; Gamarra, F.M.C.; Farias, T.M.B.; et al. Valorization of Chicken Feet By-Product of the Poultry Industry: High Qualities of Gelatin and Biofilm from Extraction of Collagen. Polymers 2020, 12, 529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haug, I.J.; Draget, K.I.; Smidsrod, O. Physical and rheological properties of fish gelatin compared to mammalian gelatin. Food Hydrocoll. 2004, 18, 203–213. [Google Scholar] [CrossRef]

- Karim, A.A.; Bhat, R. Extraction and characterisation of gelatin from Atlantic salmon (Salmo salar) skin. Food Hydrocoll. 2009, 23, 563–576. [Google Scholar] [CrossRef]

- Maciel, C.N.; Seller, L.F.F.; Souza, A.B.; Almeida, P.F. Formulation of fishburgers with the addition of different protein sources and taro flour. Ciência Rural 2021, 51, e20200380. [Google Scholar] [CrossRef]

- Eaqub Ali, M.d.; Sultana, S.; Abd Hamid, S.B.; Hossain, H.; Yehya, W.A.; Kader, A.; Bhargava, S.K. Gelatin controversies in food, pharmaceuticals, and personal care products: Authentication methods, current status, and future challenges. Crit Rev Food Sci. Nutr. 2018, 58, 1495–1511. [Google Scholar] [CrossRef]

- Prosekov, A.Y.; Voroshilin, R.A. Gelatin production—Market status and prospects, alternative sources, production technologies. ВСЁ О МЯСЕ 2020, 5S, 265–268. [Google Scholar] [CrossRef]

- Badii, F.; Howell, N.K. Fish gelatin: Structure, gelling properties and interaction with egg albumen proteins. Food Hydrocoll. 2006, 20, 630–640. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Montero, P.; Fernández-Mantín, F.; Gómez-Guillén, M.C. Physico-chemical and film-forming properties of bovine-hide and tuna-skin gelatin: A comparative study. J. Food Eng. 2009, 90, 480–486. [Google Scholar] [CrossRef]

- Oliveira, V.M.; Assis, C.R.A.; Costa, B.A.M.; Neri, R.C.A.; Monte, F.T.D.; Freitas, H.M.S.C.V.; França, R.C.P.; Santos, J.F.; Bezerra, R.S.; Porto, A.L.F. Physical, biochemical, densitometric and spectroscopic techniques for characterization collagen from alternative sources: A review based on the sustainable valorization of aquatic by-products. J. Mol. Struct. 2021, 1224, 129023. [Google Scholar] [CrossRef]

- Acevedo, C.A.; Olguín, Y.; Orellana, N.; Sánchez, E.; Pepczynska, M.; Enrione, J. Anatase Incorporation to Bioactive Scaffolds Based on Salmon Gelatin and Its Effects on Muscle Cell Growth. Polymers 2020, 12, 1943. [Google Scholar] [CrossRef] [PubMed]

- Almeida, P.F.; Silva, J.R.; Lannes, S.C.S.; Farias, T.M.B.; Santana, J.C.C. Quality Assurance and Economical Feasibility of an Innovative Product Obtained from a Byproduct of the Meat Industry in Brazil. Afr. J. Bus. Manag. 2013, 7, 2745–2756. [Google Scholar]

- Almeida, P.F.; Calarge, F.A.; Santana, J.C.C. Production of a product similar to gelatin from chicken feet collagen. Eng. Agrícola 2013, 33, 1289–1300. [Google Scholar] [CrossRef] [Green Version]

- Almeida, P.F.; Lannes, S.C.S. Effects of chicken by-product gelatin on the physicochemical properties and texture of chocolate spread. J. Texture Stud. 2017, 48, 392–402. [Google Scholar] [CrossRef]

- Pereira, F.H.; Sassi, R.J. Rough sets and principal components analysis: A comparative study on customer database attributes selection. Afr. J. Bus. Manag. 2012, 6, 3822–3828. [Google Scholar]

- Chen, T.-Y.; Wang, H.-P.; Wang, J.-C. Fuzzy automata based on Atanassov fuzy sets and applications on consumers’ advertising involvement. Afr. J. Bus. Manag. 2012, 6, 865–880. [Google Scholar]

- Pourahmad, A.A.; Neshat, M.; Baghi, A. Service quality assessment in the academic library: Use of hybrid fuzzy expert system. Afr. J. Bus. Manag. 2012, 6, 11511–11529. [Google Scholar]

- De Pelsmaeker, S.; Gellynck, X.; Delbaere, C.; Declercq, N.; Dewettinck, K. Consumer-driven product development and improvement combined with sensory analysis: A case-study for European filled chocolates. Food Qual. Prefer. 2015, 41, 20–29. [Google Scholar] [CrossRef]

- Almeida, S.S.; Alves, W.A.L.; Araújo, S.A.; Santana, J.C.C.; Narain, N.; Souza, R.R. Use of simulated annealing in standardization and optimization of the acerola wine production. Food Sci. Technol. 2014, 34, 292–297. [Google Scholar] [CrossRef] [Green Version]

- Santana, J.C.C.; Dias, C.G.; Souza, R.R.; Tambourgi, E.B. Applying of neural network on the wine sensorial analysis from Barbados cherry. J. Food Process Eng. 2010, 33, 365–378. [Google Scholar] [CrossRef]

- Curvelo-Santana, J.C.; Ehrhardt, D.D.; Tambourgi, E.B. Otimização da produção de álcool de mandioca. Ciência E Tecnol. De Aliment. 2010, 30, 613–617. [Google Scholar] [CrossRef] [Green Version]

- Severo Júnior, J.B.; Almeida, S.S.; Narain, N.; Souza, R.R.; Santana, J.C.C.; Tambourgi, E.B. Wine clarification from Spondias mombin L. pulp by hollow fiber membrane system. Process Biochem. 2007, 42, 1516–1520. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks: A Comprehensive Foundation, 3rd ed.; Prentice-Hall, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Kohonen, T. Self-Organized Formation of Topologically Correct Feature Maps. Biol. Cybern. 1982, 43, 59–69. [Google Scholar] [CrossRef]

- Alves, W.A.L.; Araújo, S.A.D.; Pessota, J.H.; Santos, R.A.B.O.D. A Methodology for Sensory Evaluation of Food Products Using Self-Organizing Maps and K-Means Algorithm. Appl. Mech. Mater. 2013, 263–266, 2191–2194. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, Y.; Shen, S.; Luo, Y.; Gao, L. Comparison of Arrhenius model and artificial neuronal network for the quality prediction of rainbow trout (Oncorhynchus mykiss) fillets during storage at different temperatures. LWT Food Sci. Technol. 2015, 60, 142–147. [Google Scholar] [CrossRef]

- Ouyang, Q.; Chen, Q.; Zhao, J. Intelligent sensing sensory quality of Chinese rice wine using near infrared spectroscopy and nonlinear tools. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 154, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Low, M.Y.; Zhou, W. Development of a partial least squares-artificial neural network (PLS-ANN) hybrid model for the prediction of consumer liking scores of ready-to-drink green tea beverages. Food Res. Int. 2018, 103, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Lu, A.; Wei, X.; Cai, R.; Xiao, S.; Yuan, H.; Gong, J.; Chu, B.; Xiao, G. Modeling the effect of vibration on the quality of stirred yogurt during transportation. Food Sci. Biotechnol. 2020, 29, 889–896. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, T.; Salauddin, M.; Hazra, S.K.; Chakraborty, R. Comparative classification efficiency of self-organizing map, principal component analysis, and hierarchical cluster Analysis for normal dairy and differently pineapple fortified rasgulla. Es Food Agrofor. 2020, 1, 94–105. [Google Scholar] [CrossRef]

- Benvenga, M.A.C.; Librantz, A.F.H.; Santana, J.C.C.; Tambourgi, E.B. Genetic algorithm applied to study of the economic viability of alcohol production from Cassava root from 2002 to 2013. J. Clean. Prod. 2016, 113, 483–494. [Google Scholar] [CrossRef]

- Severo, J.B., Jr.; De Sá Oliveira, L.S.; Sardeiro, F.S.; De Souza, R.R.; Lopes, F.L.G.; Santana, J.C.C.; Tambourgi, E.B. Response surface methodology to evaluation the recovery of amylases by hollow fiber membrane. Braz. Arch. Biol. Technol. 2007, 50, 713–718. [Google Scholar] [CrossRef] [Green Version]

- Leite, N.S.; Lima, A.A.B.; Santana, J.C.C.; Lopes, F.L.G.; Lédo, A.S.; Tambourgi, E.B.; Souza, R.R. Determination of optimal condition to obtain the bromelain from pineapple plants produced by micropropagation. Braz. Arch. Biol. Technol. 2012, 55, 647–652. [Google Scholar] [CrossRef]

- Vilanova Neta, J.L.; Lédo, A.S.; Lima, A.A.B.; Santana, J.C.C.; Leite, N.S.; Ruzende, D.S.; Silva, D.P.; Souza, R.R. Bromelain enzyme from pineapple: In vitro activity study under different micropropagation conditions. Appl. Biochem. Biotechnol. 2012, 168, 234–246. [Google Scholar] [CrossRef]

- Rosa, J.M.; Tambourgi, E.B.; Santana, J.C.C.; Araujo, M.C.; Ming, W.C.; Trindade, N. Development of colors with sustainability: A comparative study between dyeing of cotton with reactive and vat dyestuffs. Text. Res. J. 2014, 84, 1009–1017. [Google Scholar] [CrossRef]

- AOAC-Association of Official Analytical Chemists. Official Methods of Analysis, 15th ed.; AOAC: Washington, DC, USA, 1996. [Google Scholar]

- Ehab, K.; Abouldahab, O.; Hassan, A.; El-Sayed, K.M.F. Alvogyl and absorbable gelatin sponge as palatal wound dressings following epithelialized free gingival graft harvest: A randomized clinical trial. Clin. Oral. Investig. 2020, 24, 1517–1525. [Google Scholar] [CrossRef]

- Muyonga, J.H.; Cole, C.G.B.; Duodu, K.G. Fourier transform infrared (FTIR) spectroscopic study of acid soluble collagen and gelatin from skins and bones of young and adult Nile perch (Lates niloticus). Food Chem. 2004, 86, 325–333. [Google Scholar] [CrossRef]

- Miranda, A.C.; Klepa, R.B.; Farias, T.M.B.; Santana, J.C.C. Quantification study of Azithromycin drugs in soil, by the infrared technique with Fourier Transform (IFTR). Revista Ambiente e Agua 2019, 14, e2268. [Google Scholar] [CrossRef] [Green Version]

- Abedinia, A.; Nafchi, A.M.; Sharifi, M.; Ghalambor, P.; Oladzadabbasabadi, N.; Ariffin, F.; Huda, N. Poultry gelatin: Characteristics, developments, challenges, and future outlooks as a sustainable alternative for mammalian gelatin. Trends Food Sci. Technol. 2020, 104, 14–26. [Google Scholar] [CrossRef]

- Nizar, N.N.A.; Hossain, M.; Sultana, S.; Ahamad, M.N.; Johan, M.R.; Eaqub Ali, M. Quantitative duplex real-time polymerase chain reaction assay with TaqMan probe detects and quantifies Crocodylus porosus in food chain and traditional medicines. Food Addit. Contam. Part A 2019, 36, 825–835. [Google Scholar] [CrossRef]

- Lucato, W.C.; Vieira Jr, M.; Vanalle, R.M.; Salles, J.A.A. Model to measure the degree of competitiveness for auto parts manufacturing companies. Int. J. Prod. Res. 2012, 50, 5508–5522. [Google Scholar] [CrossRef]

- Berssaneti, F.T.; Assumpção, A.; Nakao, O.S. Engineering, procurement and construction (EPC): What are the variables that impact the success of the projects currently running in Brazil? Gest. Prod. 2014, 21, 95–109. [Google Scholar] [CrossRef] [Green Version]

- Miranda, A.C.; Silva Filho, S.C.; Tambourgi, E.B.; Santana, J.C.C.; Vanalle, R.M.; Guerhardt, F. Analysis of the costs and logistics of biodiesel production from used cooking oil in the metropolitan region of Campinas (Brazil). Renew. Sustain. Energy Rev. 2018, 88, 373–379. [Google Scholar] [CrossRef]

- Santana, J.C.C.; Miranda, A.C.; Yamamura, C.L.K.; Filho, S.C.S.; Tambourgi, E.B.; Ho, L.L.; Berssaneti, F.T. Effects of air pollution on human health and costs: Current situation in São Paulo, Brazil. Sustainability 2020, 12, 4875. [Google Scholar] [CrossRef]

- Maceta, P.R.M.; Berssaneti, F.T. Comparison of project portfolio management practices in the public and private sectors in Brazil: Characteristics, similarities, and differences. Int. J. Manag. Proj. Bus. 2019, 13, 1405–1422. [Google Scholar] [CrossRef]

- Cardoso, J.F.; Casarotto Filho, N.; Miguel, P.A.C. Application of quality function deployment for the development of an organic product. Food Qual. Prefer. 2015, 40, 180–190. [Google Scholar] [CrossRef]

| Gelatin-Base Gel Samples | x1 | x2 | Gelatin (g/100 g) | Sugar (g/100 g) |

|---|---|---|---|---|

| Gelatin A | −1 | −1 | 1.903 | 7.1 |

| Gelatin B | 1 | −1 | 3.806 | 7.1 |

| Gelatin C | −1 | 1 | 1.903 | 28.6 |

| Gelatin D | 1 | 1 | 3.806 | 28.6 |

| Gelatin E | 0 | 0 | 2.857 | 17.9 |

| Gelatin F | 0 | 0 | 2.857 | 17.9 |

| Gelatin G | 0 | 0 | 2.857 | 17.9 |

| Composition * | (g/100 g) | Sub-Composition (g/100 g) |

|---|---|---|

| Moisture | 9.749 | |

| Minerals | 4.807 | |

| Na | 0.0285 ± 1.10−4 * | |

| Mg | 0.0088 ± 3.10−5 | |

| Ca | 0.0081 ± 4.10−5 | |

| S | 0.0072 ± 4.10−5 | |

| K | 0.0041 ± 1.10−6 | |

| P | 0.0008 ± 8.10−6 | |

| Si | 0.0001 ± 8.10−6 | |

| Lipids | 6.919 | |

| Proteins | 78.525 | |

| Gelatin | 70.90 ± 0.52 ** | |

| Gel strength, bloom | 294.79 ± 0.50 *** | |

| Calories (kcal) | 376.37 |

| Sample | Colour a | Aroma b | Flavour c | Texture d | General Appearance e |

|---|---|---|---|---|---|

| Gelatin A | 3.76 | 2.68 | 2.60 | 2.32 | 2.80 |

| Gelatin B | 4.60 | 3.10 | 2.70 c | 5.88 | 3.72 |

| Gelatin C | 4.38 | 4.16 | 4.18 c | 3.64 | 3.64 |

| Gelatin D | 5.92 | 5.30 | 5.76 c | 6.76 | 6.06 |

| Gelatin E | 4.76 | 4.08 | 4.28 c | 5.30 | 4.9 |

| Gelatin F | 4.72 | 4.54 | 4.14 c | 4.40 | 4.3 |

| Gelatin G | 5.90 | 4.90 | 5.16 c | 6.10 | 5.32 |

| Gelatin H | 7.32 | 7.36 | 7.34 c | 7.2 | 7.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santana, J.C.C.; Almeida, P.F.; Costa, N.; Vasconcelos, I.; Guerhardt, F.; Boukouvalas, D.T.; Alves, W.A.L.; Mendoza, P.C.; Gamarra, F.M.C.; Llanos, S.A.V.; et al. Combination of Computational Techniques to Obtain High-Quality Gelatin-Base Gels from Chicken Feet. Polymers 2021, 13, 1289. https://doi.org/10.3390/polym13081289

Santana JCC, Almeida PF, Costa N, Vasconcelos I, Guerhardt F, Boukouvalas DT, Alves WAL, Mendoza PC, Gamarra FMC, Llanos SAV, et al. Combination of Computational Techniques to Obtain High-Quality Gelatin-Base Gels from Chicken Feet. Polymers. 2021; 13(8):1289. https://doi.org/10.3390/polym13081289

Chicago/Turabian StyleSantana, José C. C., Poliana F. Almeida, Nykael Costa, Isabella Vasconcelos, Flavio Guerhardt, Dimitria T. Boukouvalas, Wonder A. L. Alves, Pedro C. Mendoza, Felix M. C. Gamarra, Segundo A. V. Llanos, and et al. 2021. "Combination of Computational Techniques to Obtain High-Quality Gelatin-Base Gels from Chicken Feet" Polymers 13, no. 8: 1289. https://doi.org/10.3390/polym13081289