Abstract

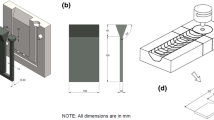

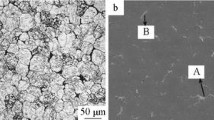

Friction Stir Processing (FSP) is a solid-state thermomechanical processing technique that enables local grain refinement, densification, and homogenization of microstructure in metallic components. Here, FSP is applied to thin sheets of high-pressure die cast AM60 to address the porosity and heterogeneities inherent to the casting process. In this work, microstructure characterization is correlated to improvements in the static mechanical properties of the Mg-Al-Mn alloy system at various FSP processing conditions. Notably, there is a significant increase in the ductility and ultimate tensile stress of the system following FSP. The dominant deformation mechanisms for the as-cast material and the FSP material are investigated. Finally, the improvement in mechanical properties is discussed with respect to implications on fatigue life improvement in future work.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Long, R.S., E. Boettcher, and D. Crawford, Current and Future Uses of Aluminum in the Automotive Industry. JOM, 2017. 69(12): p. 2635–2639.

Furuta, T., Chapter 4 - Automobile applications of titanium, in Titanium for Consumer Applications, F. Froes, M. Qian, and M. Niinomi, Editors. 2019, Elsevier. p. 77–90.

Das, S., Magnesium for automotive applications: Primary production cost assessment. JOM, 2003. 55(11): p. 22–26.

Horstemeyer, M.F., et al., High cycle fatigue mechanisms in a cast AM60B magnesium alloy. Fatigue & Fracture of Engineering Materials & Structures, 2002. 25(11): p. 1045–1056.

Rettberg, L.H., et al., Low-Cycle Fatigue Behavior of Die-Cast Mg Alloys AZ91 and AM60. Metallurgical and Materials Transactions A, 2012. 43(7): p. 2260–2274.

Cavaliere, P. and P.P. De Marco, Fatigue behaviour of friction stir processed AZ91 magnesium alloy produced by high pressure die casting. Materials Characterization, 2007. 58(3): p. 226–232.

Dickerson, T.L. and J. Przydatek, Fatigue of friction stir welds in aluminium alloys that contain root flaws. International Journal of Fatigue, 2003. 25(12): p. 1399–1409.

Jana, S., et al., Effect of friction stir processing on fatigue behavior of an investment cast Al–7Si–0.6 Mg alloy. Acta Materialia, 2010. 58(3): p. 989–1003.

Ma, Z.Y., Friction Stir Processing Technology: A Review. Metallurgical and Materials Transactions A, 2008. 39(3): p. 642–658.

Mishra, R.S. and Z.Y. Ma, Friction stir welding and processing. Materials Science and Engineering: R: Reports, 2005. 50(1): p. 1–78.

Huang, Y., et al., Dynamic recrystallization and mechanical properties of friction stir processed Mg-Zn-Y-Zr alloys. Journal of Materials Processing Technology, 2017. 249: p. 331–338.

Yuan, W., et al., Influence of grain size and texture on Hall–Petch relationship for a magnesium alloy. Scripta Materialia, 2011. 65(11): p. 994–997.

Nelaturu, P., et al., Influence of friction stir processing on the room temperature fatigue cracking mechanisms of A356 aluminum alloy. Materials Science and Engineering: A, 2018. 716: p. 165–178.

Dahle, A.K., et al., Formation of defect bands in high pressure die cast magnesium alloys. Journal of Light Metals, 2001. 1(2): p. 99–103.

Gourlay, C.M., H.I. Laukli, and A.K. Dahle, Defect Band Characteristics in Mg-Al and Al-Si High-Pressure Die Castings. Metallurgical and Materials Transactions A, 2007. 38(8): p. 1833–1844.

Moscovitch, N., et al., The Effect of Porosity on the Microstructure and Mechanical Properties of Die Cast Mg Alloys. 2006.

Ritchie, R.O., Mechanisms of fatigue-crack propagation in ductile and brittle solids. International Journal of Fracture, 1999. 100(1): p. 55–83.

Cavaliere, P. and P.P. De Marco, Friction stir processing of AM60B magnesium alloy sheets. Materials Science and Engineering: A, 2007. 462(1): p. 393–397.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Garcia, D., Das, H., Ma, X., Roosendaal, T., Grant, G.J., Komarasamy, M. (2022). Exploring the Microstructure-Property Relationship of Mg-Al-Mn Alloys Enhanced via Friction Stir Processing. In: Maier, P., Barela, S., Miller, V.M., Neelameggham, N.R. (eds) Magnesium Technology 2022. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-92533-8_33

Download citation

DOI: https://doi.org/10.1007/978-3-030-92533-8_33

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92532-1

Online ISBN: 978-3-030-92533-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)