Abstract

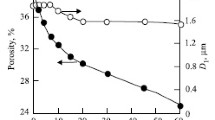

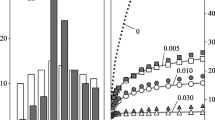

A sintering model, taking into account the effect of particle-size distribution and the effect of grain growth, has been derived. The model predicts a dependence of densification on the width of the particle-size distribution. This dependence is strongly affected by the occurrence of grain growth. Prior to the occurrence of grain growth, the model predicts that the densification rate increases and then decreases as the particle-size distribution width of the original powder increases. After grain growth occurs, the densification rate decreases as the particle-size distribution width of the starting powder increases.

Similar content being viewed by others

References

T.-S. Yeh and M. D. Sacks, J. Am. Ceram. Soc. 71 (1988) C484.

J. S. Chappel, T. A. Ring and J. D. Birchall, J. Appl. Phys. 60 (1986) 383.

J. P. Smith and G. L. Messing, J. Am. Ceram. Soc. 67 (1984) 238.

B. R. Patterson and L. A. Benson, Prog. Powder Metall. 39 (1983) 215.

M. F. Yan, R. M. Cannon, U. Chowdhry and H. K. Bowen, Bull. Am. Ceram. Soc. 56 (1977) 3.

W. H. Rhodes, J. Am. Ceram. Soc 64 (1981) 19.

E. A. Barringer and H. K. Bowen, ibid. 65 (1982) C 199.

M. F. Yan, R. M. Cannon Jr, H. K. Bowen and U. Chowdhry, Mater. Sci. Eng. 60 (1983) 275.

M. D. Sacks and T.-Y. Tseng, J. Am. Ceram. Soc. 67 (1984) 532.

E. Barringer, N. Jubb, B. Fegley, R. L. Pober and H. K. Bowen, in “Ultrastructure Processing of Ceramics, Glasses, and Composites”, edited by L. L. Hench and D. R. Ulrich (Wiley Interscience, New York, 1984) pp. 568–75.

R. L. Coble, J. Am. Ceram. Soc. 56 (1973) 461.

G. L. Messing and G. Y. Onoda Jr, ibid. 68 (1981) 468.

G. C. Kuzynski, Trans. AIME 185, (1949) 169.

N. Cabrera, ibid. 188 (1950) 667.

W. D. Kingery and M. Berg, J. Appl. Phys. 26 (1955) 1205.

R. L. Coble, J. Am. Ceram. Soc. 41 (1958) 55.

R. L. Coble, in “Kinetics of High-Temperature Processes”, edited by W. D. Kingery (Technology Press, MA and Wiley, New York, 1959) pp. 146–63.

G. C. Kuzynski, L. Abernethy and J. Allan, ibid.in “, pp. 163–71.

D. L. Johnson and I. V. Culter, J. Am. Ceram. Soc. 46 (1963) 541.

Idem, ibid. 46 (1963) 545.

D. L. Johnson and T. M. Clarke, Acta Metall. 12 (1964) 1173.

P. D. Wilcox and I. B. Culter, J. Am. Ceram. Soc. 49 (1966) 249.

D. L. Johnson, J. Appl. Phys. 40 (1969) 192.

W. S. Young and I. B. Culter, J. Am. Ceram. Soc. 53 (1970) 659.

R. L. Coble, J. Appl. Phys. 41 (1970) 4798.

D. L. Johnson and I. B. Culter, in “Phase Diagrams, Materials Science and Technology, II”, edited by A. M. Alper (Academic Press, New York, 1970) pp. 265–91.

W. R. Rao and I. B. Culter, J. Am. Ceram. Soc. 55 (1972) 170.

R. L. Coble, J. Appl. Phys. 32 (1961) 787.

Idem, ibid. 32 (1961) 793.

P. J. Jorgensen, J. Am. Ceram. Soc. 48 (1965) 207.

R. L. Coble, ibid. 36 (1965) 2327.

R. L. Coble and T. K. Gupta, in “Sintering and Related Phenomena”, edited by G. C. Kuzynski, N. A. Hooton and C. F. Gibbon (Gordon and Breach, New York, 1967) pp. 423–41.

A. K. Kakar, J. Am. Ceram. Soc. 51 (1968) 236.

T. K. Gupta, ibid. 52 (1969) 166.

D. L. Johnson, ibid. 53 (1970) 574.

P. Kumar and D. L. Johnson, ibid. 57 (1974) 65.

T. K. Gupta, ibid. 55 (1972) 276.

J. H. Rosolowski and C. Greskovich, ibid. 58 (1975) 177.

H. Suzuki, J. Appl. Phys. 49 (1978) 4238.

M. Hiller, Acta Metall. 13 (1965) 227.

K. S. Venkataraman and R. A. Dimilia, J. Am. Ceram. Soc. 72 (1989) 33.

R. J. Brook and J. H. Rosoloski, in “Treatise on Solid State Sintering, 4”, edited by N. B. Nannay (Plenum, New York 1976) pp. 621–69.

W. S. Coblenz, J. M. Dynys, R. M. Cannon and R. L. Coble, in “Sintering Process”, edited by G. C. Kuzynski (Gordon and Breach, New York, 1979) pp. 141–57.

Jyh-Ming Ting, PhD thesis, Department of Materials Science and Engineering, University of Cincinnati, Cincinnati, OH (1991).

W. D. Kingery, and B. Frankois, in “Sintering and Related Phenomena”, edited by G. C. Kuzynski, N. A. Hooten and C. F. Gibbon (Gordon and Breach, New York, 1967) pp. 471–98.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ting, J.M., Lin, R.Y. Effect of particle-size distribution on sintering. JOURNAL OF MATERIALS SCIENCE 29, 1867–1872 (1994). https://doi.org/10.1007/BF00351306

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00351306