Abstract

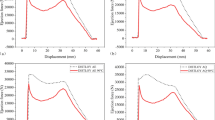

The hot-working characteristics of the metal-matrix composite (MMC) Al-10 vol % SiC-particulate (SiCp) powder metallurgy compacts in as-sintered and in hot-extruded conditions were studied using hot compression testing. On the basis of the stress-strain data as a function of temperature and strain rate, processing maps depicting the variation in the efficiency of power dissipation, given by η = 2m/(m+1), where m is the strain rate sensitivity of flow stress, have been established and are interpreted on the basis of the dynamic materials model. The as-sintered MMC exhibited a domain of dynamic recrystallization (DRX) with a peak efficiency of about 30% at a temperature of about 500°C and a strain rate of 0.01 s−1. At temperatures below 350°C and in the strain rate range 0.001–0.01 s−1 the MMC exhibited dynamic recovery. The as-sintered MMC was extruded at 500°C using a ram speed of 3 mm s−1 and an extrusion ratio of 10∶1. A processing map was established on the extruded product, and this map showed that the DRX domain had shifted to lower temperature (450°C) and higher strain rate (1 s−1). The optimum temperature and strain rate combination for powder metallurgy billet conditioning are 500°C and 0.01 s−1, and the secondary metal-working on the extruded product may be done at a higher strain rate of 1 s−1 and a lower temperature of 425°C.

Similar content being viewed by others

References

A. D. DIVECHA, S. G. FISHMAN and S. D. KARMARKAR, J. Metals 33 (1981) 12.

S. V. NAIR, J. K. TIEN and R. C. BATES, Int. Met. Rev. 30 (1985) 275.

H. L. OEGEL, J. C. MALAS, S. M. DORAIVELU and V. A. SHENDE, in “Metals Hand Book”, Vol. 14 (American Society of Metals, Metals Park, Ohio, 1987) p. 417.

F. R. TULER and T. F. KLIMOWICZ, in “Metal and Ceramic Matrix Composites; Processing, Modelling and Mechanical Behaviour” (The Minerals, Metais and Materials Society, Warrendale, Pa, 1990) p. 271.

Y. V. R. K. PRASAD, H. L. GEGEL, S. M. DORAIVELU, J. C. MALAS, J. T. MORGAN, K. A. LARK and D. R. BARKER, Met. Trans. 15A (1984) 1883.

J. M. ALEXANDER, in “Modelling Hot Deformation of Steels — An Approach to Understanding and Behaviour” (Springer-Verlag, Berlin, 1989) p. 101.

R. RAJ, Met. Trans. 12A (1981) 1089.

H. J. MCQUEEN, E. EVANGELISTA, J. BOWLES and G. CRAWFORD, Met. Sci. 18 (1984) 395.

N. RAVICHANDRAN and Y. V. R. K. PRASAD, Bull. Mater. Sci. 14 (1991) 1241.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bhat, B.V.R., Mahajan, Y.R., Roshan, H.M. et al. Processing maps for hot-working of powder metallurgy 1100 Al-10 vol % SiC-particulate metal-matrix composite. Journal of Materials Science 28, 2141–2147 (1993). https://doi.org/10.1007/BF00367575

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00367575