Summary

A magnetic method for measuring the amount of metal contaminants retained in the lungs was applied to workers in an iron- and steelmaking plant.

Knowledge of properties of airborne particles is required for the calibration of the measuring method and for the estimation of the biological activities of the particles.

In this study chemical composition, morphology of typical particles, and magnetic properties of dusts and fumes from different parts of the plant are presented. The amounts of contaminants retained in the lungs of 27 workers representing typical occupations in the production process were measured. The levels of lung contamination of the iron and steel workers were compared with those of manual metal arc steel welders and with those of foundry workers.

In the sintering department, the dust is generated by mechanical handling of raw materials. Iron content of the dust is low, and iron is mainly in the form of magnetite.

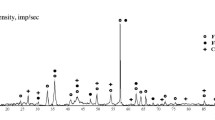

Blast furnace fumes contain mainly iron in the form of iron oxides condensed from pig iron. According to X-ray diffraction analysis, electron micrographs, and magnetic measurements, fume particles have a hematite/ magnetite shell structure. Similar iron fume particles are generated in the continuous casting process.

The main part of the converter dust is glass-like slag where iron is dissolved in form of iron 11 oxides.

Concentrations of toxic metals in metal fumes were low, e.g., the highest concentration of lead was 0.2%.

The iron concentration of dusts and fumes was 25–59% Fe. Typical saturation magnetic moment was 42Am2/kg varying between 15 and 92 Am2/ kg. The equation between saturation magnetic moment and the iron content for dusts in the iron and steel production process was: Ms = 0.66 × Fe % + 11,r = 0.79.

The mean magnetic moments of the dusts and fumes in different parts of the plant were equal so that the same calibration coefficient can be used for all dusts when measuring the amount of contaminants retained in the lungs.

The approximate amount of lung-retained contaminants varied from 20–200 mg in blast furnace workers, from 10–40 mg in sintering plant workers, and from 2–20 mg in workers in continuous casting process. The mean remanent magnetic fields were in the same groups 1.4 nT, 0.47 nT, and 0.29 nT, respectively.

Comparison between different occupational groups exposed to metal aerosols in different iron-based processes indicated that the level of lung contamination was lowest among iron and steel workers, next highest among foundry workers, and highest among stainless steel manual metal arc welders.

Similar content being viewed by others

References

Cohen D (1973) Ferromagnetic contamination in the lungs and other organs of the human body. Science 180:745–748

Cohen D (1975) Measurements of the magnetic fields produced by the human heart, brain, and lungs. IEEE Trans Magn 11:694–700

Gordon J (1978) How BSC's Redcar project is setting a standard for environmental control. Iron Steel Int 2:27–29

Her Majesty's Stationary Office (1970). Fumes from welding and flame cutting. London, p 35

Kalliomäki P-L (1977) Measurement of magnetic lung contamination in vivo. Evaluation of the method and its application to the welders. Doctoral dissertation, institute of Occupational Health, Helsinki, p 65

Kalliomäki P-L, Alanko K, Korhonen O, Mattsson T, Vaaranen V, Koponen M (1978 a) Amount and distribution of welding fume lung contaminants among arc welders. Scand J Work Environ Health 4:122–130

Kalliomäki P-L, Korhonen O, Vaaranen V, Kalliomäki K, Koponen M (1978 b) Lung retention and clearance of shipyard arc welders. Int Arch Occup Environ Health 42:83–90

Kalliomäki P-L, Korhonen O, Mattsson T, Sortti V, Vaaranen V, Kalliomäki K, Koponen M (1979) Lung contamination among foundry workers. Int Arch Occup Environ Health 43:85–91

Kalliomäki P-L, Kalliomäki K, Heinonen O, Korhonen O, Mattsson T, Nordman H, Vaaranen V (1980a) Health status and lung contamination of stainless steel welders. (To be published)

Kalliomäki K, Kalliomäki P-L, Kelhä V, Vaaranen V (1980b) Instrumentation for measuring the lung contamination of steel welders. Ann Occup Hyg 23:175–184

Kühnen G (1976) Bestimmung der Konzentration von silikogenen, toxischen und belastigenden Stauben an Arbeitsplatzen der Hüttenindustrie. Wissenschaftlicher Abschlulßbericht der Forschung PS 169. Staubforschungsinstitut, Bonn, S 214

Mašek V (1977) Eigenschaften von Flugstauben in Arbeitsstätten eines Hochofenbetriebes. Staub Reinhalt Luft 37:104–106

Mašek V (1978) Wirkung von Staubemissionen aus Eisenhätten auf den Boden. Staub Reinhalt Luft 38:493–495

Nicola AG (1976) Fugitive emissions control in the steel industry. Iron Steel Eng 53:25–30

Siltanen E, Koponen M, Kokko A, Engström B, Reponen J (1976) Dust exposure in Finnish foundries. Scand J Work Environ Health [Suppl] 1:19–31

Sittig M (1977) Particulates and fine dust removal. Noyes Data Corporation, New Jersey, pp 281–333

Smith CG, Whitehead C (1979) Control of fugitive emissions in the steel industry. Iron Steel Eng 56:49–56

Statens offentliga utredningar (1975). Working environment in the steel industry (in Swedish). Stockholm

Stern R (1977) A chemical, physical, and biological assay of welding fume. Part I. Fume characteristics. The Danish Welding Institute, Glostrup, p 16 and appendices

Tossavainen A (1976) Metal fumes in foundries. Scand J Work Environ Health [Suppl] 1:42–49

Zakharov AN, Lebedinets YP (1977) Labor safety at No 9 blast furnace of Krivrozhstal' plant. Metallurgist 21:330–332

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Koponen, M., Gustafsson, T., Kalliomäki, K. et al. Dusts in a steel-making plant. Int. Arch Occup Environ Heath 47, 35–45 (1980). https://doi.org/10.1007/BF00378326

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00378326