Abstract

Gluconic acid fermentation has been widely used for the analysis of various aspects of kinetics and gas liquid transfer of oxygen. Most of these studies are, however, restricted to processes with bacteria. Mathematical models for industrially important productions with fungi have not been elaborated.

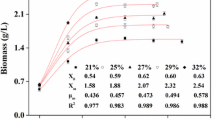

In the experimental part of this work computer coupled fermentations of gluconic acid production with Aspergillus niger NRRL 3 have been performed. Knowledge of the stoichiometric relationship in the key reaction (glucose oxidase) provides an excellent opportunity for on-line estimation of glucose, biomass and product gluconate from oxygen uptake and carbon dioxide evolution rates.

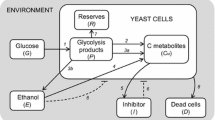

Starting then from experimental observations on the pH-depending oxygen kinetics of gluconic acid formation and influences of product concentrations on the growth of Aspergillus niger a mathematical framework is developed in which the kinetics of growth and production are coupled with gas liquid oxygen transfer. The model can be successfully applied to simulations of the experimental results of gluconic acid fermentations with cyclic addition of glucose. An important aspect in the coupling of transport and microbial reaction in this model is the incorporation of the influence of sugar and gluconate on the solubility of oxygen and k La via changes of viscosities and molecular diffusivities.

With the development of such a comprehensive model, it appears feasible to investigate the influence of various process conditions (sugar feeding, pressure, optimal pH profiles) and to study their possible impacts on the productivity of the overall process.

Similar content being viewed by others

Abbreviations

- a 0,a 1,a 2 :

-

coefficients in the polynom function for the specific production rate (Eq. (17))

- b 0,b 1,b 2 :

-

coefficients in the polynom function for the specific growth rate (Eq. (19))

- c 0,c 1,c 2 :

-

coefficients in pH = f(t)

- c L :

-

concentration of dissolved oxygen

- c *L :

-

saturation concentration of oxygen

- \(D_{O_2 } \) :

-

molecular diffusivity of oxygen in the fermentation fluid

- g :

-

acceleration due to gravity

- K M :

-

Michaelis-Menten constant in the oxygen kinetics

- k La:

-

volumetric mass transfer coefficient

- \(m_{Co_{_2 } } \) :

-

maintenance coefficient for carbon dioxide

- m O :

-

maintenance coefficient for oxygen

- m S :

-

maintenance coefficient for substrate

- m 1,m2 :

-

coefficients (Eqs. (21), (22))

- P :

-

product concentration

- P G :

-

power input under gassed conditions

- P max :

-

critical gluconate concentration for growth

- \(Q_{O_2 } \) :

-

volumetric oxygen uptake rate

- \(Q_{CO_2 } \) :

-

volumetric carbon dioxide evolution rate

- \(q_{O_2 } \) :

-

specific oxygen uptake rate

- S :

-

substrate concentration

- Sc:

-

Schmidt number

- t :

-

time

- t:

-

time at which pH control is switched off

- t * :

-

final fermentation time

- t 1 :

-

switching time for optimal pH control

- T :

-

time constant in the delay of product formation

- u G0 :

-

superficial gas velocity

- V L :

-

liquid volume

- V G :

-

gas flow rate

- X :

-

biomass concentration

- \(Y_{Co_2 } \) :

-

volume fraction of carbon dioxide in the air

- \(Y_{o_2 } \) :

-

volume fraction of oxygen in the air

- YX/O \(Y_{x/co_2 } \) 79-08}:

-

yield coefficients

- Y P/O, Y P/S :

-

yield coefficients

- η :

-

dynamic viscosity

- μ :

-

specific growth rate

- μ max :

-

maximum specific growth rate

- ν P :

-

specific production rate

- ν P,max :

-

maximum specific production rate

- ν :

-

kinematic viscosity

- ϱ :

-

density of the liquid

- α :

-

at the inlet

- ω :

-

at the outlet

References

Yamane, T.; Shimizu, S. 1984: Fed-batch techniques in microbial processes. In: Fiechter, A. (Ed.): Adv. Biochem. Eng./Biotechnol. 30, 147–194

Wang, N. S.; Stephanopoulos, G. 1984: Computer applications for fermentation processes. CRC Critical Reviews in Biotechnology, vol. 2, Issue 1, 1–103

Parulekar, S. J.; Lim, H. C. 1985: Modelling, optimization and control of semi-batch bioreactors. In: Fiechter, A. (Ed.): Adv. Biochem. Eng./Biotechnol. 32, 207–258

Reuss, M. 1983: Mathematical models for coupled oxygen transfer and microbial kinetics in bioreactors. In: Halme, A. (Ed.): Modelling and control of biochemical processes, pp. 43–55. Oxford, New York, Toronto, Sydney, Paris, Frankfurt: Pergamon Press

Oosterhuis, N. M. G.; Kossen, N. W. F. 1984: Dissolved oxygen concentration profiles in a production-scale bioreactor. Biotechnol. Bioeng. 26, 546–550

Oosterhuis, N. M. G.; Kossen, N. W. F.; Olivier, A. P. C; Schenk, E. S. 1985: Scale down and optimization of the gluconic acid fermentation by Gluconobacter oxydans. Biotechnol. Bioeng. 27, 711–720

Gaden, E. L., Jr. 1959: Fermentation process kinetics. J. Biochem. Microbiol. Technol. Eng. 1, 413–429

Wells, P. A.; Moyer, A. J.; Stubbs, J. J.; Herrick, H. T.; May, O. E. 1937: Gluconic acid production. Effect of pressure, air flow, and agitation on gluconic acid production by submerged mold growth. Industr. Eng. Chem. 29, 653–656

Moyer, A. J.; Wells, P. A.; Stubbs, J. J.; Herrick, H. T.; May, O. E. 1937: Gluconic acid production. Development of inoculum and composition of fermentation solution for gluconic acid production by submerged mold growths under increased air pressure. Industr. Eng. Chem. 29, 777–781

Gastrock, E. A.; Porges, N.; Wells, P. A.; Moyer, A. J. 1938: Gluconic acid production on pilot-plant scale. Effect of variables on production by submerged mold growths. Industr. Eng. Chem. 30, 782–789

Moyer, A. J.; Umberger, A. J.; Stubbs, J. J. 1940: Fermentation of concentrated solutions of glucose to gluconic acid. Industr. Eng. Chem. 32, 1379–1383

Humphrey, A. E.; Reilly, P. J. 1965: Kinetic studies of gluconic acid fermentations. Biotechnol. Bioeng. 7, 229–243

Koga, S.; Burg, C. R.; Humphrey, A. E. 1967: Computer simulation of fermentation systems. Appl. Microbiol. 15, 683–689

Hsieh, D. P. H.; Silver, R. S.; Mateles, R. I. 1969: Use of the glucose oxidase system to measure oxygen transfer rates. Biotechnol. Bioeng. 11, 1–18

Bull, D. N.; Kempe, L. L. 1979: Kinetics of the conversion of glucose to gluconic acid by Pseudomonas ovalis. Biotechnol. Bioeng. 12, 273–290

Tanner, R. D. 1970: An enzyme kinetic model for describing fermentation processes. Biotechnol. Bioeng. 12, 831–843

Ghose, T. K.; Mukhopadhyay, S. N. 1976: Kinetic studies of gluconic acid fermentation in horizontal rotary Fermenter by Pseudomonas ovalis. J. Ferment. Technol. 54, 738–750

Ghose, T. K; Ghosh, P. 1976: Kinetic analysis of gluconic acid production by Pseudomonas ovalis. J. Appl. Chem. Biotechnol. 26, 768–777

Ghosh, P.; Ghose, T. K. 1978: Oxygen transfer in gluconic acid fermentation. J. Ferment. Technol. 56, 139–143

Nyeste, L.; Sevella, B.; Szigeti, L.; Szoke, A.; Hollo, J. 1980: Modelling and off-line optimization of batch gluconic acid fermentation. Europ. J. Appl. Microbiol. Biotechnol. 10, 87–94

Zetelaki, K.; Vas, K. 1968: The role of aeration and agitation in the production of glucose oxidase in submerged culture. Biotechnol. Bioeng. 10, 45–59

Zetelaki, K. 1970: The role of aeration and agitation in the production of glucose oxidase in submerged culture. II. Biotechnol. Bioeng. 12, 379–397

Novać, M.; Fencl, Z. 1973: Kinetic analysis of the relationship between batch and continuous cultivation of Aspergillus niger. Biotechnol. Bioeng. Symp. Ser. No. 4, 43–52

Machek, F.; Fencl, Z. 1973: Differentiation of filamentous microorganisms as a basis for understanding of product formation. Biotechnol. Bioeng. Symp. Ser. No. 4, 129–142

Takamatsu, T.; Shioya, S.; Furuya, T. 1981: Mathematical model for gluconic acid fermentation by Aspergillus niger. J. Chem. Tech. Biotechnol. 31, 697–704

Gibson, Q. H; Swoboda, B. E. P.; Massey, V. 1964: Kinetics and mechanism of action of glucose oxidase. J. Biol. Chem. 239, 3927–3934

Lockwood, L. B. 1979: Production of organic acids by fermentation. In: Peppler, H. J.; Perlman, D. (Eds.): Microbial Technology I, pp. 355–387. London, New York: Academic Press

Röhr, M.; Kubicek, C. P. 1983: Gluconic Acid. In: Rehm, H.-J.; Reed, G. (Eds.): Biotechnology — A comprehensive Treatise in 8 Volumes, vol. 3 (Ed.: Dellweg, H.) Chapter 3 e, pp. 455–465. Weinheim, Deerfield Beach (Florida), Basel: Vlg. Chemie

Deutsches Patentamt: DE 1817 907 (Ger. Pat): Verfahren zur Herstellung einer wäßrigen Lösung von Gluconsäure und einem wasserlöslichen Gluconat durch submerse Vergärung von Glucose

Lien, O. G., Jr. 1959: Determination of gluconolactone, galactonolactone and their free acids by the hydroxamate method. Ann. Chem. 31, 1363–1366

Lenz, R.; Zoll, G. 1982: Rapid determination of sodium gluconate and glucose in fermentation fluids. In: Molnar, I. (Ed.): Practical Aspects of Modern HPLC, pp. 355–361. Berlin, New York: Walter De Gruyter & Co.

Zabriskie, D. W.; Arminger, W. B.; Humphrey, A. E. 1976: Applications of computers to the indirect measurement of biomass concentration and growth rate by component balancing. In: Jefferis, R. P. (Ed.): Workshop Computer Applications in Fermentation Technology, GBF Monograph Ser. No. 3, pp. 59–72. Weinheim, New York: Vlg. Chemie

Zabriskie, D. W.; Humphrey, A. E. 1978: Real-time estimation of aerobic batch fermentation biomass concentration by component balancing. AIChE J. 24, 138

Reuss, M.; Jefferis, R. P.; Lehmann, J. 1976: Application of an on-line system of coupled computer to fermentation modelling. In: Jefferis, R. P. (Ed.): Workshop Computer Application in Fermentation Technology, GBF Monograph Ser. No. 3, pp. 107–124. Weinheim, New York: Vlg. Chemie

Roels, J. A. 1983: Energetics and kinetics in biotechnology. Amsterdam, New York, Oxford: Elsevier Biomedical Press

Watson, T. G. 1970: Effects of sodium chloride on steadystate growth and metabolism of Saccharomyces cerevisiae. J. Gen. Microbiol. 64, 91–99

Halme, A. (Ed.), 1983: Modelling and control of biotechnical processes. Oxford, New York, Toronto, Sydney, Paris, Frankfurt: Pergamon Press

Johnson, A. (Ed.), 1985: Modelling and control of biotechnological processes. 1st IFAC Symp., Noordwijkerhout, The Netherlands, 11–13 Dec. 1985, IFAC Proc. Ser. Oxford, New York, Toronto, Sydney, Frankfurt: Pergamon Press

Blanch, H. W. 1981: Invited review microbial growth kinetics. Chem. Eng. Commun. 8, 181–211

Bentley, R. 1963: Glucose oxidase. In: Boyer, P. D.; Lardy, H.; Myrbäck, K. (Eds.): The Enzymes, vol. 7, pp. 567–586. New York, London: Academic Press

Popović, M.; Niebelschütz, H.; Reuss, M. 1979: Oxygen solubilities in fermentation fluids. Europ. J. Appl. Microbiol. Biotechnol. 8, 1–15

Schumpe, A. 1985: Gas solubilities in biomedia. In: Rehm, H.-J.; Reed, G. (Eds.): Biotechnology — A comprehensive treatise in 8 Volumes, vol. 2 (Ed.: Brauer, H.), Chap. 10, pp. 159–170. Weinheim, Deerfield Beach (Florida), Basel: Vlg. Chemie

Henzler, H.-J. 1982: Verfahrenstechnische Auslegungsgrundlagen für Rührbehälter als Fermenter. Chem.-Ing.-Tech. 54, 461–476

Van't Riet, K. 1979: Review of measuring methods and results in non viscous gas-liquid mass transfer in stirred vessels. Ind. Eng. Chem. Process Des. Dev. 18, 367–375

Niebelschütz, H. 1982: Sauerstoffübergang Gas/Flüssigkeit in gerührten Bioreaktoren. Diss. im Fachgebiet Biotechnologie, TU Berlin

Niebelschütz, H.; Reuss, M. 1984: Measurements of oxygen diffusivities in polysaccharide solutions. In: Third European Congress on Biotechnology, vol.II, pp. II579-II584. Weinheim, Deerfield Beach (Florida), Basel: Vlg. Chemie

Rai, V. R.; Constantinides, A. 1973: Mathematical modelling and optimization of the gluconic acid fermentation. AIChE Symp. Ser. 69, 114

Constantinides, A.; Rai, V. R. 1974: Application of the continuous maximum principle to fermentation processes. Biotechnol. Bioeng. Symp. Ser. No. 4, 663–680

Ray, W. H.; Szekely, J. 1973: Process optimization. New York, London, Sydney, Toronto: John Wiley & Sons

Yoshida, T. Sueki, M.; Taguchi, H.; Kulprecha, S.; Nilubol, N. 1981: Modelling and optimization of steroid transformation in a mixed culture. Eur. J. Appl. Microbiol. Biotechnol. 11, 81–88

Guthke, R.; Knorre, W. A. 1981: Optimal substrate profile for antibiotic fermentations. Biotechnol. Bioeng. 23, 2771–2777

Cheruy, A.; Durand, A. 1979: Optimization of erythromycin biosynthesis by controlling pH and temperature: theoretical aspects and practical applications. Biotechnol. Bioeng. Symp. Ser. No. 9, 303–320

Höcker, H. 1979: Untersuchungen zum Leistungseintrag und Stoffübergang in Rührreaktoren. Diss. Univ. Dortmund

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Reuss, M., Fröhlich, S., Kramer, B. et al. Coupling of microbial kinetics and oxygen transfer for analysis and optimization of gluconic acid production with Aspergillus niger. Bioprocess Engineering 1, 79–91 (1986). https://doi.org/10.1007/BF00387499

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00387499