Abstract

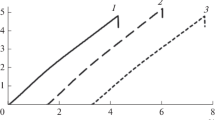

The disparate thermal expansion properties of the fibres and matrices in high-performance composites lead to an inevitable build up of residual thermal stresses during fabrication. We first discuss the thermal expansion behaviour of thermoplastic and thermoset polymers that may be used as high-performance composite matrices. The three classes of polymers considered are epoxies, amorphous thermoplastics, and semicrystalline thermoplastics. The relevant thermal expansion data for prediction of the magnitude of the residual stresses in composites is the zero (atmospheric)-pressure thermal expansion data; these data are plotted for a range of thermoplastics and a typical epoxy. Using the technique of photoelasticity, we have measured the magnitude of the residual stresses in unidirectional graphite composites with an amorphous thermoplastic matrix (polysulfone) and with an epoxy matrix (BP907). The temperature dependence of the residual stress build up and the resulting magnitude of the residual stresses correlate well with the thermal and physical properties of the matrix resin.

Similar content being viewed by others

References

G. Lubin, Ed., “Handbook of Composites” (Van Nostrand Reinhold, New York, 1982).

B. Yates, B. A. McCalla, L. N. Phillips, D. M. Kingston-Lee andK. F. Rogers,J. Mater. Sci. 14 (1979) 1207.

J. M. Mahishi andD. F. Adams,ibid. 18 (1983) 447.

B. Yates, B. A. McCalla, J. P. Sargent, K. F. Rogers, L. N. Phillips andD. M. Kingston-Lee,ibid. 13 (1978) 2217.

B. Wunderlich, “Macromolecular Physics”, Vol. 3, “Crystal Melting” (Academic Press, New York, 1980).

P. Zoller, Proceedings of the Eleventh North American Thermal Analysis Society, Vol. II (1981).

H. W. Starkweather, P. Zoller andG. A. Jones,J. Polymer Sci. Polymer Phys. Ed. 21 (1983) 295.

P. Zoller,ibid. 20 (1982) 1453.

R. Simha andT. Somcynsky,Macromol. 2 (1969) 342.

R. Simha,ibid. 10 (1977) 1025.

P. Zoller,J. Polymer Sci. Polymer Phys. Ed. 18 (1980) 157.

Idem, ibid. 18 (1980) 897.

R. K. Jain andR. Simha,ibid. 17 (1979) 1929.

A. Quach andR. Simha,J. Phys. Chem. 76 (1972) 416.

P. Zoller andH. H. Hoehn,J. Polymer Sci. Polymer Phys. Ed. 20 (1982) 2385.

P. Zoller, R. Bolli, V. Pahud andH. Ackermann,Rev. Sci. Instrum. 47 (1976) 948.

P. Zoller,J. Polymer Sci. Polymer Phys. Ed. 16 (1978) 1261.

P. Zoller andP. Bolli,J. Macromol. Sci. Phys. B18 (1980) 555.

J. Brandrup andE. H. Immergut, Eds., “Polymer Handbook” (Interscience, New York, 1967).

A. W. Handry, “Photoelastic Analysis” (Pergamon Press, New York, 1966).

UDEL Polysulfone Product Data, Union Carbide (1981).

J. A. Nairn,Polymer Composites, in press.

J. D. Ferry, “Viscoelastic Properties of Polymers” (Wiley, New York, 1970).

H. T. Hahn,J. Comp. Mater. 10 (1976) 266.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nairn, J.A., Zoller, P. Matrix solidification and the resulting residual thermal stresses in composites. J Mater Sci 20, 355–367 (1985). https://doi.org/10.1007/BF00555929

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00555929