Abstract

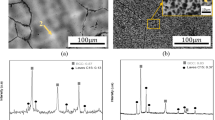

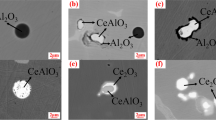

The improvement in oxidation resistance produced by small additions of active elements to Al 2O3-forming CoCrAl alloys is primarily dependent on the formation of oxide pegs which grow into the alloy around the internal oxide particles of the active element; void formation at the alloy-scale interface is also suppressed. The distribution of these pegs is critical and this paper demonstrates that an internal oxidation pretreatment can be used to convert the active element to its oxide in a controlled manner, thereby optimizing the peg distribution. Al2O3-forming CoCrAl containing 1% Hf or Ce is internally oxidized in a sealed quartz capsule containing a 50/50 powder mixture of CoAl-Al2O3; it was not possible to oxidize internally Y-containing alloys. The isothermal and cyclic oxidation resistance of these alloys is superior to that of alloys not given a prior treatment. Detailed metallographic examination indicates that the prior internal oxidation treatment produces a finer, more uniform distribution of oxide pegs penetrating into the alloy which is more efficient in combatting scale spallation. Furthermore, the lower residual hafnium content in the alloy minimizes large HfO2 precipitates and the formation of gross Al2O3 intrusions, which can initiate scale failure. Thus, by internally oxidizing the alloy first, the advantages of a high alloy Hf content (1%) in producing sufficient oxide pegs, but of the right size, coupled with minimal thickening of the surface scale, can be achieved.

Similar content being viewed by others

References

G. R. Wallwork and A. Z. Hed,Oxid. Met. 3, 229 (1971).

C. S. Giggins and F. S. Pettit,Metall. Trans. 3, 1071 (1971).

H. H. Davis, H. C. Graham, and I. A. Kvernes,Oxid. Met. 3, 431 (1971).

M. S. Seltzer, B. A. Wilcox, and J. Stringer,Metall. Trans. 3, 2391 (1972).

J. Stringer, B. A. Wilcox, and R. I. Jaffee,Oxid. Met. 5, 11 (1972).

J. Stringer and I. G. Wright,Oxid. Met. 5, 59 (1972).

I. G. Wright and B. A. Wilcox,Metall. Trans. 5, 953 (1974).

J. Stringer, A. Z. Hed, G. R. Wallwork, and B. A. Wilcox,Corros. Sci. 12, 625 (1972).

I. G. Wright and J. Stringer,Metallography 6, 65 (1973).

I. M. Allam, D. P. Whittle, and J. Stringer,Oxid. Met. 12, 35 (1978).

C. S. Giggins and F. S. Pettit, Final Rept., Aerospace Res. Labs., Wright Patterson AFB, Contract No. F33615-72-C-1702 (1976).

J. K. Tien and F. S. Pettit,Metall. Trans. 3, 1587 (1972).

I. A. Kvernes,Oxid. Met. 6, 45 (1973).

J. D. Kuenzly and D. L. Douglass,Oxid. Met. 8, 139 (1974).

J. M. Francis and W. H. Whitlow,Corros. Sci. 5, 701 (1965).

C. S. Wukusick and J. F. Collins,Mater. Res. Stand. 4, 637 (1964).

E. Felten,J. Electrochem. Soc. 108, 490 (1961).

B. Lustman,Trans. Met. Soc. A.I.M.E. 188, 995 (1950).

J. Stringer,Metall. Rev. 11, 113 (1966).

H. Pfeiffer,Werkst. Korres. 8, 574 (1957).

J. M. Francis and J. A. Jutson,Corros. Sci. 8, 574 (1968).

F. A. Golightly, F. H. Stott, and G. C. Wood,Oxid. Met. 10, 163 (1976).

D. P. Whittle, M. E. El Dahshan, and J. Stringer,Corros. Sci. 17, 879 (1977).

O. T. Goncel, J. Stringer, and D. P. Whittle,Corros. Sci. 18, 701 (1978).

Author information

Authors and Affiliations

Additional information

Formerly: Department of Metallurgy and Materials Science, University of Liverpool, Liverpool, England.

Rights and permissions

About this article

Cite this article

Allam, I.M., Whittle, D.P. & Stringer, J. Improvements in oxidation resistance by dispersed oxide addition: Al2O3-forming alloys. Oxid Met 13, 381–401 (1979). https://doi.org/10.1007/BF00609306

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00609306