Abstract

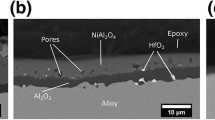

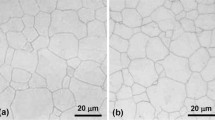

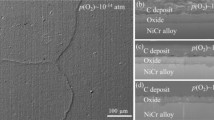

The high-temperature oxidation behavior of Ni3Al (Ni-13.2 wt.% Al) with and without additions of 0.5 wt.% yttrium has been studied over the range of 900–1200°C in air. None of the commonly accepted rate laws were followed by the kinetics. Although the weight gains of samples containing yttrium were consistently 10–20% greater than those without yttrium, the steady-state scaling rates were identical. A quantitative x-ray diffraction technique was used to determine the kinetics of growth of the protective alpha-alumina layer (one of several oxides formed). The alumina growth followed the parabolic rate law under all conditions studied. The rate-controlling transport process in alumina was the enhanced diffusion of oxygen down grain boundaries. The presence of yttrium as nickel-rich intermetallics promoted the formation of nickel aluminate (spinel). A marked increase in scale adherence was observed for short times. At longer times, however, the outer layer of spinel and unreacted nickel oxide spalled off along with some of the inner alumina layer. Loss of adherence was caused by a complex yttrium-aluminum oxide which formed by the solid-state reaction of yttria and alumina. The poor scale adherence on Ni3Al was due to the formation of voids at the alloy-oxide interface. These voids concentrated the athermal stresses above the oxide-to-metal adherence strength. The voids were produced as a result of the selective oxidation of aluminum resulting from a “Kirkendall” effect in the substrate. During the selective oxidation process, a vacancy flux directed from the matrix to the metaloxide interface resulted in a supersaturation of vacancies. Equilibrium was maintained by the condensation of excess vacancies. The presence of yttrium as either nickel-rich intermetallics or internal oxide prevented the voids from forming. The yttrium-rich particles relieved the matrix of vacancy supersaturation by providing vacancy sinks. The chemical nature of the particles does not seem important. A necessary and sufficient condition for an effective vacancy sink appears to be the presence of an incoherent boundary between particle and matrix.

Similar content being viewed by others

References

W. Hessenbruck,Metallen und Legierungen für Hole Temperaturen, Teil I (J. Springer, Berlin, 1940), pp. 31–37.

D. L. Douglass and J. S. Armijo, The effect of silicon and manganese on the oxidation mechanism of Ni-20Cr,Oxid. Met. 2, 207–231 (1970).

D. L. Douglass and J. S. Armijo, The influence of manganese and silicon on the oxidation behavior of Co-20Cr,Oxid. Met. 3, 185–202 (1971).

J. K. Tien and F. S. Pettit, Mechanism of oxide adherence on Fe-25Cr-4Al (Y or Sc) alloys,Metall. Trans. 3, 1587–1599 (1972).

Y. Oishi and W. D. Kingery, Self-diffusion of oxygen in single-crystal and polycrystalline aluminum oxide,J. Chem. Phys.,33, 480–486 (1960).

A. E. Paladino and W. D. Kingery, Aluminum ion diffusion in aluminum oxide,J. Chem. Phys. 37, 957–962 (1962).

A. E. Paladino and R. L. Coble, Effect of grain boundaries on diffusional-controlled processes in aluminum oxide.J. Am. Ceram. Soc. 46, 133–136 (1963).

R. L. Coble and Y. H. Guerard, Creep of polycrystalline aluminum oxide,J. Am. Ceram. Soc. 46, 353–354 (1963).

S. I. Warshaw and F. H. Norton, Deformation behavior of polycrystalline aluminum oxide,J. Am. Ceram. Soc. 45, 479–486 (1962).

E. M. Passmore and T. Vasilos, Creep of dense, pure fine-grained aluminum oxide,J. Am. Ceram. Soc. 49, 166–168 (1966).

G. C. Wood and B. Chattopadhyay, Transient oxidation of Ni-base alloys,Corros. Sci. 10, 471–480 (1970).

F. S. Pettit, Oxidation mechanisms for nickel-aluminum alloys at temperatures between 900°C and 1300°C,Trans. AIME 239, 1296–1305 (1967).

G. C. Wood and F. H. Stott, Establishment and breakdown of α-Al2O3 scales on Ni-Al alloys at high temperatures,Brit. Corros. J. 6, 247–256 (1971).

H. Fischmeister, Mechanism and kinetic effects of oxide growth, Part I: Whiskers,Mém. Sci. Rev. Mét. 62, 211–215 (1965).

E. A. Gulbransen, Model of oxidation processes occurring in oxide whiskers and platelets on iron at 400°C to 500°C,Mém. Sci. Rev. Mét. 62, 254–260 (1965).

D. L. Douglass, The role of oxide plasticity on the oxidation behavior of metals: a review,Oxid. Met. 1, 127–142 (1969).

Batelle Memorial Institute,Engineering Properties of Selected Ceramic Materials (American Ceramic Society, Columbus, Ohio, 1966).

J. M. Francis and W. H. Whitlow, The effect of yttrium on the high-temperature oxidation resistance of some Fe-Cr base alloys in carbon dioxide,Corros. Sci. 5, 701–710(1965).

J. M. Francis and J. A. Jutson, High temperature oxidation of an Fe-Cr-Al-Y alloy in CO2,Corros. Sci. 8, 445–449 (1968).

G. C. Wood, Fundamental factors determining the mode of scaling of heat-resistant alloys,Werkst, Korros. 22, 491–503 (1971).

I. Kvernes and P. Kofstad, Studies on the behavior of nickel-base superalloys at high temperatures, Air Force Materials Laboratory, Wright-Patterson Air Force Base, Dayton, Ohio, Tech. Rep. AFML-TR-70-103, 1970.

J. E. Antill and K. A. Peakall, Influence of an alloy addition of yttrium on the oxidation behavior of an austenitic and a ferritic steel in carbon dioxide,J. Iron Steel Inst. 205, 1136–1142 (1967).

K. C. Radford and P. L. Pratt, The mechanical properties of impurity-doped alumina single crystals,Proc. Brit. Ceram. Soc. 15, 182–202 (1970).

J. Stringer, The effect of alloying on oxidation: Quantitative treatments,Metall. Rev. 11, 113–128 (1966).

D. Kuhlmann-Wilsdorf, R. Maddin, ad H. G. Wilsdorf, Point defect hardening in facecentered cubic metals, inStrengthening Mechanisms in Solids (American Society for Metals, Metals Park, Ohio, 1962), pp. 137–178.

M. M. Janssen and G. D. Rieck, Reaction diffusion and Kirkendall-effect in the nickel-aluminum system,Trans. AIME 239, 1372–1385 (1967).

R. W. G. Wyckoff,Crystal Structures, Vols. 2 and 3, 2nd ed. (Interscience, New York, 1964), pp. 5–395 (Vol. 2) and 222–225 (Vol. 3).

I. Warshaw and R. Roy, Stable and metastable equilibrium in the systems Y2O3-Al2O3 and Gd2O3-Fe2O3,J. Am. Ceram. Soc. 42, 434–438 (1959).

O. J. Whittemore, Jr. and N. N. Ault, Thermal expansion of various ceramic materials to 1500°C,J. Am. Ceram. Soc. 39, 443–444 (1956).

T. K. Gupta and J. Valentich, Thermal expansion of yttrium aluminum garnet,J. Am. Ceram. Sac. 54, 355–356 (1971).

A. Taylor and R. W. Floyd, The constitution of nickel-rich alloys of the nickel-titanium-aluminum system,J. Inst. Met. 81, 25–32 (1952).

Author information

Authors and Affiliations

Additional information

This work is based on a portion of the dissertation of J. D. Kuenzly, accepted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in Engineering, University of California, Los Angeles, California, 1973.

Supported by the Advanced Research Projects Agency of the Department of Defense under Contract No. DAHC 15-70-G-15.

Rights and permissions

About this article

Cite this article

Kuenzly, J.D., Douglass, D.L. The oxidation mechanism of Ni3Al containing yttrium. Oxid Met 8, 139–178 (1974). https://doi.org/10.1007/BF00612170

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00612170