Abstract

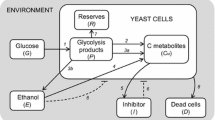

The scale-down procedure can be used to optimize and scale up fermentation processes. The first step in this procedure, a theoretical analysis of the process at a large scale, must give information about the regime, or bottle necks, ruling the process. In order to verify the theoretical results the process analysis has been applied to the fed-batch baker's yeast production at a laboratory scale. The results of this analysis are compared with results from fed-batch experiments. It was concluded that if only one mechanism is ruling the process, for instance mass transfer, the results of the analysis are quite clear. If more than one mechanism is important, for example mass transfer and liquid mixing, additional knowledge is needed to predict the behaviour of the process.

Concerning the baker's yeast production, it was concluded that if oxygen limitation occurs, liquid mixing is of little importance.

Similar content being viewed by others

Abbreviations

- C kg/m3 :

-

concentration

- C * kg/m3 :

-

saturation concentration

- D m:

-

diameter

- D E m2/s:

-

effective dispersion coefficient

- d m:

-

holes of the sparger

- F sm3/s:

-

substrate flow to the fermentor

- g m/s2 :

-

gravitational acceleration

- H m:

-

height

- k La s−1 :

-

volumetric mass transfer coefficient based on the liquid volume

- L m:

-

length

- m skg/(kg·s):

-

maintenance coefficient

- OTR kg/(m3·s):

-

oxygen transfer rate

- OUR kg/(m3·s):

-

oxygen uptake rate

- r kg/(m3·s):

-

reaction rate

- t s:

-

time

- V m3 :

-

volume

- v m/s:

-

velocity

- v sm/s:

-

superficial gas flow rate

- y ijkg/kg:

-

yield of componentj oni

- μ s−1 :

-

specific growth rate

- τ s:

-

time constant

- φ gm3/s:

-

gas flow rate

- 0:

-

value att=0

- cir :

-

liquid circulation

- e :

-

ethanol

- f :

-

feed concentration

- g :

-

gas phase

- in :

-

flow going to the fermentor

- l :

-

liquid phase

- m :

-

mixing

- mt :

-

mass transfer

- o, O2 :

-

oxygen

- oc :

-

oxygen consumption

- out :

-

flow coming out the fermentor

- s :

-

substrate

- sa :

-

substrate addition

- sc :

-

substrate consumption

- x :

-

biomass

References

Sweere, A. P. J.; Mesters, J. R.; Luyben, K. Ch. A. M.; Kossen, N. W. F.: Regime analysis of the baker's yeast production. Proc. Int. Conf. Bioreactor Fluid Dynamics, BHRA, Cambridge, 15–17 April 1896, pp. 217–230.

Sweere, A. P. J.; Luyben, K. Ch. A. M.; Kossen, N. W. F.: Regime analysis and scale-down: tools to investigate the performance of bioreactors. Enz. Microb. Technol. 9 (1987) 386–398

Sweere, A. P. J.; Van Dalen, J. P.; Kishoni, E.; Luyben, K. Ch. A. M.; Kossen, N. W. F.: Theoretical analysis of the baker's yeast production: an experimental verification at a laboratory scale. Part I: liquid mixing and mass transfer. Bioproc. Engr. (1988)

Moser, A.: Special cultivation techniques. In: Rehm, H.-J.; Reed, G. (Eds.): Biotechnology, vol. 2, pp. 311–347. Weinheim: VCH Verlagsgesellschaft, 1985

Sweere, A. P. J.; Mesters, J. R.; Janse, L.; Luyben, K. Ch. A. M.; Kossen, N. W. F.: Experimental simulation of oxygen profiles and their influence on the baker's yeast production. Part I: One-fermentor-system. Accepted for publication in Biotechnol. Bioeng. (1987)

Reed, G.: Production of baker's yeast. In: Prescott and Dunn's Industrial Microbiology. Westport: The Avi Publishing Company, Inc. 1982

Linde, Aktiengesellschaft, Patent Request 7710188, The Netherlands 1977.

Luttmann, R.; Buchholz, H.; Zahrzewski, W.; Schügerl, K.: Identification of mass transfer parameters and process simulation of SCP production processes in air-lift tower reactors with an external loop. Biotechn. Bioeng. 24 (1982) 817–835

Deckwer, W.-D.; Hallensleben, J. Popovic, M.: Exclusion of gas sparger influence on mass transfer in bubble columns. Can. J. Chem. Eng. 58 (1980) 190–197

Alvarez-Cuenca, M.; Baker, C. G. J.; Bergougnou, M. A.: Oxygen mass transfer in bubble columns. Chem. Eng. Sci. 35 (1980) 1121–1127

Barford, J. P.; Hall, R. J.: An examination of the Crabtree-effect in Saccharomyces cerevisiae: the role of respiratory adaptation. J. Gen. Microbiol. 114 (1979) 267–275

Rieger, M.; Kappeli, O.; Fiechter, A.: THe role of limited respiration in the incomplete oxidation of glucose by Saccharomyces cerevisiae. J. Gen. Microbiol. 129 (1983) 653–661

Van Dijken, J. P.; Scheffers, W. A.: Redox balances in the metabolism of sugars by yeast. FEMS Microbiol. Rev. 32 (3/4) (1986) 199–224

Heynen, J. J.; Van't Riet, K.: Mass transfer, mixing and heat transfer phenomena in low viscosity bubble column reactors. Chem. Eng. J. 28 (1984) B21-B42

Vogelbusch Gesellschaft mbH, Patent 1339847, Austria 1975.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sweere, A.P.J., van Dalen, J.P., Kishoni, E. et al. Theoretical analysis of the baker's yeast production: An experimental verification at a laboratory scale. Bioprocess Engineering 4, 11–17 (1989). https://doi.org/10.1007/BF00612665

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00612665