Abstract

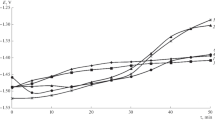

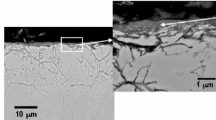

This paper reports the successful co-deposition of inclusion-free chromiummodified aluminide coatings using a pack-cementation process. The substrate used was the nickel-base superalloy, René 80H. The coatings were of the outward-diffusion type; however, unlike the usual outward-diffusion coatings, the present coatings were relatively free of pack inclusions. The coatings consisted of α-Cr precipitates in a matrix of β-NiAl. The morphology and distribution of the α-Cr precipitates could be adjusted to the extent that two types of coating structures could be obtained. The Type I coating structure contained lamellar α-Cr precipitates situated in the surface region of the coating, whereas the Type II coating structure contained small, spheroidal α-Cr precipitates distributed throughout the outer of a two-layered coating. Both coating types exhibited significantly improved hot-corrosion resistance in a 0.1% SO2-O2 environment at 900°C compared to a commercial aluminide coalting. A study of the corrosion behavior of Type I coatings containing pack inclusions showed that the inclusions were deleterious to the corrosion resistance of the coatings. The corrosion behavior of chromium-aluminide coatings was dependent on both the distribution and amount of α-Cr precipitates in the coating.

Similar content being viewed by others

References

D. Chatterji, R. C. De Vries, and G. Romeo, inAdv. in Con. Sci. Tech., Vol.6, M. G. Fontana and R. W. Staehle, eds. (Plenum Press, New York, 1976), pp. 1–87.

G. W. Goward and L. W. Cannon,J. Eng. Gas. Turb. Pow. 110, 150–154 (1988).

G. W. Goward and D. H. Boone,Oxid. Met. 3, 475–495 (1971).

G. F. Slattery,Met. Technol. 10, 41–51 (1983).

M. Mévrel, C. Duret, and R. Pichoir,Mater. Sci. Technol. 2, 201–206 (1986).

J. Stringer,Mater. Sci. Technol. 3, 482–493 (1987).

G. W. Meetham,J. Mater. Sci. 26, 853–860 (1991).

T. N. Rhys-Jones,Mater. Sci. Technol. 4, 421–430 (1988).

J. Stringer, inSurface Engineering, R. Kossowsky and S. C. Singhal, eds. (Martinus Nijhoff Publishers, Boston, 1984), pp. 561–587.

G. W. Goward,Mater. Sci. Technol. 2, 194–200 (1986).

Coatings Technology for Hot Components of Industrial Combustion Turbines: A Review of the State of the Art, EPRIAP-5078, Project 2388-3, Final Report, February 1987, p. 2–2.

M. G. Hocking, V. Vasantasree, and P. S. Sidky,Metallic and Ceramic Coatings: Production, High Temperature Properties and Applications (Longman Scientific & Technical, Essex, 1989), p. 41.

P. Streiff and D. H. Boone, inCoatings and Bimetallics for Aggressive Environments, R. D. Sisson, ed. (American Society for Metals, Metals Park, OH, 1985), pp. 159–169.

V. A. Ravi and R. A. Rapp, inHigh-Temperature Ordered Intermetallic Alloys III, Vol. 133, C. T. Lin, A. I. Taub, N. S. Stoloff, and C. C. Koch, eds. (MRS Symposium Proceedings, 1988), pp. 543–547.

R. A. Choquet, E. R. Naylor, and R. A. Rapp,Mater. Sci. Eng. 121A, 413–418 (1989).

R. A. Rapp, D. Wang, and T. Weisert, inHigh Temperature Coatings, M. Khobaib and R. C. Krutenat, eds. (TMS, 1986), pp. 131–141.

R. Bianco and R. A. Rapp, inHigh Temperature Materials Chemistry V., W. B. Johnson and R. A. Rapp, eds. (Electrochemical Society, Pennington, NJ, 1990), pp. 211–219.

R. Bianco, M. A. Harper, and R. A. Rapp,J. Met. 43(11), 1991, pp. 68–73.

G. H. Marijnissen, inHigh Temperature Protective Coatings, S. S. Singhal, ed. (TMS of AIME, Atlanta, GA, 1983), pp. 27–35.

R. Sivakumar,Oxid. Met. 17, 27–41 (1982).

K. Godlewski and E. Godlewska,Oxid. Met. 26, 125–138 (1986).

M. Dust, P. Deb, and D. H. Boone,J. Vac. Sci. Technol A 4, 2571–2576 (1986).

S. M. Merchant, M. R. Notis, and J. I. Goldstein,Metall. Trans. A 21A, 1901–1910 (1990).

S. M. Merchant, M. R. Notis, and J. I. Goldstein,Metall. Trans. A 21A, 1911–1919 (1990).

I. M. J. Estrada-Plata and C. W. Haworth,Mater. Sci. Technol. 2, 322–323 (1986).

B. Gleeson, D. L. Douglass, and F. Gesmundo,Oxid. Met. 34, 123–150 (1990).

A. Taylor and R. W. Floyd,J. Inst. Mater. 81, 451–464 (1952/1953).

M. Kawakami, K. S. Goto, and R. A. Rapp,Trans. Iron Steel Inst. Jpn. 20, 646–658 (1980).

N. Otsuka and R. A. Rapp,J. Electrochem. Soc. 137, 53–60 (1990).

R. A. Rapp,Corrosion 42, 568–577 (1986).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gleeson, B., Cheung, W.H., Costa, W.D. et al. The hot-corrosion behavior of novel CO-deposited chromium-modified aluminide coatings. Oxid Met 38, 407–424 (1992). https://doi.org/10.1007/BF00665662

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00665662