Abstract

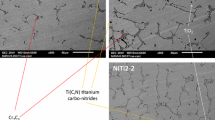

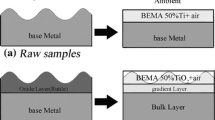

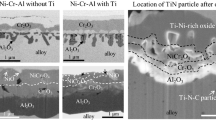

The oxidation behavior of Ti36Al, Ti35Al-0.1C, Ti35Al-1.4V-0.1C, and Ti35 Al-5Nb-0.1C (mass-%) in air and oxygen has been studied between 700 and 1000°C with the major emphasis at 900°C. Generally an oxide scale consisting of two layers, an outward- and an inward-growing layer, formed. The outward-growing part of the scale consisted mainly of TiO2 (rutile), while the inward-growing part is composed of a mixture of TiO2 and α-Al2O3. A barrier layer of Al2O3 on TiAl between the inner and the outer part of the scale was visible for up to 300 hr. Under certain conditions, the Al2O3 barrier dissolved and re-precipitated in the outer TiO2 layer. This “shift” leads to an effect similar to breakaway oxidation. Only the alloy containing Nb formed a longlasting, protective Al2O3 layer, which was established at the metal/scale interface after an incubation period of 80–100 hr. During this time, Nb was enriched in the subsurface zone up to approximately 20 w/o. The growth of the oxide scale on TiAl-V obeyed a parabolic law, because no Al2O3 barrier layer formed; large Al2O3 particles were part of the outward-growing layer. A brittle α2-Ti3Al-layer rich in O formed beneath the oxide scale as a result of preferential Al oxidation particularly when oxidized in oxygen. Oxidation in air can lead also to formation of nitrides beneath the oxide scale. The nitridation can vary between the formation of isolated nitride particles and of a metal/Ti2AlN/ TiN/oxide, scale-layer system. Under certain conditions, nitride-layer formation seemed to favor protective Al2O23 formation at the metal/scale interface, however, in general nitridation was detrimental with the consequence that oxidation was generally more rapid in air than in oxygen.

Similar content being viewed by others

References

T. Grobstein and J. Doychak, eds.,Oxidation of High-Temperature Intermetallics (The Minerals, Metals and Materials Society, Warrendale, 1988).

G. H. Meier, inOxidation of High-Temperature Intermetallics (The Minerals, Metals and Materials Society, Warrendale, 1988), p. 1.

E. A. Aitken, Corrosion behavior, inIntermetallic Compounds, Chap. 25, J. H. Westbrook, ed. (Wiley, 1967).

G. Welsch and A. J. Kahveci, inOxidation of High-Temperature Intermetattics (The Minerals, Metals and Materials Society, Warrendale, 1988), p. 207.

E. U. Lee and H. Waldman,Scripta Metall. 22, 1389 (1988).

N. S. Choudhury, H. G. Graham, and J. W. Hinze, inProperties of High Temperature Alloys with Emphasis on Environmental Effects, Z. A. Foroulis and F. S. Pettit, eds. (The Electrochemical Society, Princeton, 1976), p. 668.

K. Kasahara, K. Hashimoto, H. Doi, and T. Tsujimoto,J. Jpn. Inst. Met. 53, 58 (1989).

E. Kobayashi, M. Yoshihara, and R. Tanaka,High Temp. Technol. 8, 179 (1990).

A. Rahmel and P. J. Spencer,Oxid. Met. 35, 53 (1991).

R. A. Perkins, K. T. Chiang, G. H. Meier, and R. Miller, inOxidation of High-Temperature Intermetallics (The Minerals, Metals and Materials Society, Warrendale, 1988), p. 157.

R. A. Perkins, K. T. Chiang, and G. H. Meier,Scripta Metall. 21, 1505 (1987).

J. B. McAndrew and H. D. Kessler,Trans. AIME J. Met., 1348 (1956).

J. Subrahmanyam,J. Mater. Sci. 23, 1906 (1988).

A. Das and F. W. Vahldiek, inCorrosion and Particle Erosion at High Temperatures, V. Srinivasan and K. Vedula, eds. (The Minerals, Metals and Materials Society, Warrendale, 1989), p. 531.

M. Khobaib and F. W. Vahldiek, 2nd International SAMPE Metals Conference, Society for the Advancement of Materials and Process Eng., Dayton, Ohio, August 2–4, 1988.

K. E. Wiedemann, S. N. Sankaran, R. K. Clark, and T. A. Wallace, inOxidation of High-Temperature Intermetallics (The Minerals, Metals and Materials Society, Warrendale, 1988), p. 195.

S. J. Balsone, inOxidation of High-Temperature Intermetallics (The Minerals, Metals and Materials Society, Warrendale, 1988), p. 219.

M. J. Bennett and A. T. Tuson, Poster paper at the Conference on High Temperature Intermetallics, The Institute of Metals, London, April 30–May 1, 1991.

P. Grahle, B. Heine, and E. Fromm,Werkst. Korros. 42, 12 (1991).

K. L. Luthra,Oxid. Met. 36, 475 (1991).

P. Kofstad,High Temperature Corrosion (Elsevier, 1988), p. 295.

C. Wagner,Z. Elektrochem. 63, 772 (1959).

H. E. Bühler and H. P. Hougardy,Atlas der Interferenzschichten-Metallographie (Deutsche Gesellschaft für Metallkunde, Oberursel, 1979).

C. Coddet, G. Béranger, and J. F. Chrétien, inMaterials and Coatings to Resist High Temperature Corrosion, D. R. Holmes and A. Rahmel, eds. (Applied Science Publisher, London, 1978), p. 175.

T. B. Massalski, ed.,Binary Alloy Phase Diagrams, 2nd Ed., Vol. 3 (Amer. Soc. Metals, Metals Park, Ohio, 1990), p. 2926.

G. Inden, H. Kudielka, and A. Hellwig (private communication).

P. Kofstad, Nonstoichiometry. Diffusion, and Electrical Conductivity in Binary Metal Oxides (Wiley-Interscience, 1972), pp. 137 ff.

K. S. Førland,Acta Chimica Scandinavica 20, 2573 (1966).

P. J. Spencer (private communication).

A. Rahmel, inPassivierende Filme und Deckschichten, H. Fischer, K. Hauffe, and W. Wiederholt, eds. (Springer, Berlin, 1956), p. 122.

J. C. Schuster and J. Bauer,J. Solid State Chem. 53, 260 (1984).

S. Becker, M. Schütze, and A. Rahmel (to be published).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Becker, S., Rahmel, A., Schorr, M. et al. Mechanism of isothermal oxidation of the intel-metallic TiAl and of TiAl alloys. Oxid Met 38, 425–464 (1992). https://doi.org/10.1007/BF00665663

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00665663