Conclusions

-

1.

Chemicothermal treatment substantially increases the surface hardness of economically alloyed maraging steel 04Kh2N5MFYu.

-

2.

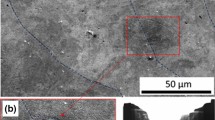

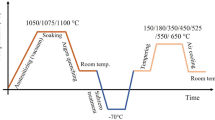

The use of steel 04Kh2N5MFYu makes it possible to reduce the nitriding, chromizing, and boriding times by a factor of three in comparison with similar processes for standard steels. The possibility of using slower cooling to obtain a martensitic structure and the formation of lamellar low-carbon martensite greatly reduce the tendency of the boride layer to crack.

-

3.

The secondary hardening effect is observed in tempering at 500–560° after carburizing and quenching of steel 04Kh2N5MFYu, which permits the use of high-temperature tempering after carburizing and quenching.

-

4.

After chromizing, the diffusion coating consists of alloyed ferrite, which is hardened by precipitation hardening in the course of aging.

Similar content being viewed by others

Literature cited

L. S. Malinov et al., “Maraging steels with a strength of 110–130 kgf/mm2,” Metalloved. Term. Obrab. Met., No. 6, 15 (1973).

L. M. Kleiner, L. I. Kogan, and R. I. Éntin, “Properties of low-carbon alloyed martensite,” Fiz. Met. Metalloved.,33, No. 4, 824 (1972).

É. S. Tsyrlin, “Nitriding of maraging steel N18K9M5T,” Metalloved. Term. Obrab. Met., No. 4, 22 (1971).

Yu. M. Lakhtin and É. S. Tsyrlin, “Nitriding of maraging steel,” Fiz. Khim. Obrab. Mater., No. 1, 101 (1973).

A. V. Belotskii, A. V. Mokhort, and V. G. Permyakov, “High-temperature x-ray analysis of nitriding of Armco iron,” Izv. Vyssh. Uchebn. Zaved., Metall., No. 5, 147 (1966).

V. G. Permyakov, A. V. Belotskii, and R. I. Barabash, “Structure and properties of diffusion zones during nitriding of chromium iron,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 4, 129 (1972).

A. V. Belotskii, V. G. Permyakov, and I. M. Samsonyuk, “Hardness of nitrided steel,” Fiz. Met. Metalloved.,26, No. 5, 942 (1969).

A. N. Minkevich, Chemicothermal Treatment of Metals and Alloys [in Russian], Mashinostroenie, Moscow (1965).

Additional information

Zhdanov Metallurgical Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 36–38, September, 1979.

Rights and permissions

About this article

Cite this article

Malinov, L.S., Korotich, I.K. Chemicothermal treatment of economically alloyed maraging steels. Met Sci Heat Treat 21, 701–703 (1979). https://doi.org/10.1007/BF00708634

Issue Date:

DOI: https://doi.org/10.1007/BF00708634