Conclusions

-

1.

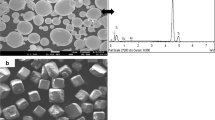

A study was made of the physical, chemical, and fabrication properties of titanium powders obtained by reduction with calcium hydride and by electrolysis. Reduced titanium powders have a large specific surface, exceeding by an order of magnitude the specific surface of electrolytic powders, and are strongly contaminated, particularly with iron.

All the powder grades investigated are characterized by excellent compressibility, reduced powder being slightly inferior in this respect to electrolytic powder. During compaction, the powders strongly adhere to the die walls, as a result of which the die becomes scored, particularly when powders containing fine fractions are used.

-

2.

During sintering, porous compacts from reduced titanium powder exhibited high shrinkage, which was due to the large specific surface of the powder. For compacts from electrolytic powder with a particle size of −1.0 + 0.25 mm, no shrinkage was observed at temperatures in the range 900–1400°C.

-

3.

From changes in the electrical conductivity of sintered compacts, it may be concluded that the temperatures of interparticle-contact stabilization are 900°C for reduction powder and 1100°C for the −0.25 mm fraction of electrolytic powder; for the −1.0 + 0.25 mm fraction of electrolytic powder, contact stabilization does not occur within the temperature range investigated.

As a result of the better sinterability of reduced powders, the mechanical properties of compacts from these powders are higher than those of compacts from electrolytic powder.

As a technique for the production of porous titanium, sintering in thoroughly-dried argon is simpler than vacuum sintering and enables porous parts to be produced with mechanical properties fulfilling the requirements of sintered-filter operation.

Similar content being viewed by others

Literature cited

S. A. Saltykov, Transactions of the Seventh Conference on Powder Metallurgy, [in Russian], Erevan (1964), p. 34.

I. S. Izrailevich and S. N. Novikov, Poroshkovaya Met., No. 5, 51 (1966).

V. N. Eremenko, Titanium and Its Alloys [in Russian], Izd-vo AN UkrSSR, Kiev (1960).

J. Norton, J. Metals, No. 8, 1, 49 (1956).

R. Beckerdicke and L. Sutcliffe, Metallurgia,39, 303 (1949).

K. Mauer, H. Grewe, and H. Weigand, DEW-Tech. Ber.,6, No. 3, 115 (1966).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 5(65), pp. 28–35, May, 1968.

Rights and permissions

About this article

Cite this article

Arensburger, D.S., Pugin, V.S. & Fedorchenko, I.M. Properties of electrolytic and reduced titanium powders and sinterability of porous compacts from such powders. Powder Metall Met Ceram 7, 362–367 (1968). https://doi.org/10.1007/BF00774529

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774529