Abstract

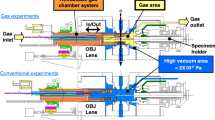

A small four-point-bend jig has been used in a scanning electron microscope (SEM) to monitor the tensile fracture processes in iron and nickel oxide scales in situ. The scales were 3–40 μm thick, the strain rate was 4×10−5 sec−1 and acoustic emission (AE) was used to correlate signals with specific cracking events. The technique provided detailed information of the failure processes, and several micrographs were taken as the crack pattern developed during testing. Failure started with short random through-scale cracks. These cracks soon formed a regular pattern. Spallation only occurred at much higher strains and resulted in very energetic AE signals. These signals were used together with the SEM observations to determine the strain to cause spallation. Measurements of the crack spacing as a function of strain showed that plastic stress relaxation by interfacial slip and/or substrate yielding processes affected cracking. Thus, the oxide remained attached to the substrate longer than would be expected from purely elastic behavior. An analysis based on the observed crack spacing at the onset of spallation gave ratios of 0.8–1.9 and ∼0.9 between tensile and interfacial strength for iron and nickel oxides scales, respectively.

Similar content being viewed by others

References

H. E. Evans,Mater. Sci. Technol. 4, 415–420 (1988).

M. M. Nagl, W. T. Evans, D. J. Hall, and S. R. J. Saunders,J. Phys., to appear.

M. M. Nagl, S. R. J. Saunders, W. T. Evans, and D. J. Hall,Corros. Sci. 35, 965–977 (1993).

P. Hancock and J. R. Nicholls,Mater. Sci. Technol. 4, 398–406 (1988).

J. Robertson and M. I. Manning,Mater. Sci. Technol. 6, 81–91 (1990).

H. E. Evans,Mater. Sci. Engineer A120, 139–146 (1989).

M. Schütze,Mater. Sci. Technol. 6, 32–38 (1990).

M. M. Nagl, Ph.D.thesis, University of Glamorgan, UK (1992).

W. Christl, A. Rahmel, and M. Schütze,Oxid. Met. 31, 35–69 (1989).

M. Schütze,Oxid. Met. 24, 199–232 (1985).

J. Barbehön, A. Rahmel, and M. Schütze,Oxid. Met. 30, 85–94 (1988).

J. Barbehön, A. Rahmel, and M. Schütze, inProc. Conf. High Temperature Alloys for Gas Turbines & Other Applications (Reidel, Dordrecht, 1986), pp. 1267–1277.

M. Schütze,Int. J. Pres. Ves. Piping 47, 293–315 (1991).

L. Berchtold, H. G. Sockel, and B. Ilschner, inBehaviour of High Temperature Alloys in Aggressive Environments (Metal Soc., London, 1980) pp. 927–941.

M. M. Nagl, D. J. Hall, and W. T. Evans, inProc. Conf. on Life Prediction of Corrodible Structures, R. Parkins, ed. (NACE, Houston, 1994).

M. Schütze, inProc. Int. Symp. on Solid State Chemistry of Advanced Materials, Y. Saito, B. Önay, and T. Maruyama, eds. (Elsevier, Amsterdam, 1992).

J. K. Tien and J. M. Davidson, inProc. Symp. on Stress Effects and the Oxidation of Metals J. V. Cathcart, ed. (AIME, 1974), pp. 200–219.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nagl, M.M., Evans, W.T., Hall, D.J. et al. Anin situ investigation of the tensile failure of oxide scales. Oxid Met 42, 431–449 (1994). https://doi.org/10.1007/BF01046759

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01046759