Summary

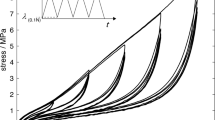

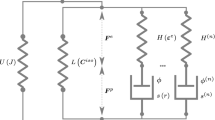

A geometric nonlinear and thermodynamical consistent constitutive theory is proposed, which allows the representation of the thermomechanical behaviour of carbon black filled rubber. In a recent paper [1] it was shown that the mechanical behaviour of this material is mainly influenced by nonlinear elasticity coupled with some inelastic effects, in particular the Mullins-effect, nonlinear rate dependence and a weak equilibrium hysteresis. In the present paper, the Mullins-effect is not taken into consideration. At first we discuss a uniaxial approach, based on a simple spring dashpot system of viscoplasticity. The essential feature of this model is a decomposition of the total stress into a rate independent equilibrium stress and a nonlinear rate dependent overstress. The equilibrium stress is decomposed into a sum of two terms as well: The first term, the elastic part of the equilibrium stress, is a nonlinear function of the total strain, and the second term, the so-called hysteretic part, depends in a rate independent manner on the strain history. Both the overstress and the hysteretic part of the equilibrium stress are determined by nonlinear elasticity relations which depend on internal variables. These internal variables are inelastic strains, and the corresponding evolution equations are developed in consideration of the second law of thermodynamics. Accordingly, we demonstrate that the principle of non-negative dissipation is satisfied for arbitrary deformation processes. In a further step, we transfer the structure of this model to the three-dimensional and geometric nonlinear case. In a certain sense similar to finite deformation elasto-plasticity, we introduce two multiplicative decompositions of the deformation gradient into elastic and inelastic parts. The first decomposition is defined with respect to the overstress and the second one with respect to the hysteretic part of the equilibrium stress. Consequently, two intermediate configurations are induced, which lead two different decompositions of the Green's strain tensor into elastic and inelastic parts. The latter are the internal variables of the model. For physical reasons, we define the corresponding stress tensors and derivatives in the sense of the concept of dual variables [7], [39]. Theconstitutive equations for the overstress and for the hysteretic part of the equilibrium stress are specified by nonlinear elasticity relations, formulated with respect to the different intermediate configurations. In order to facilitate a separate description of inelastic bulk and distortional effects, we introduce kinematic decompositions of the deformation gradient into volumetric and distortional parts. Numerical simulations demonstrate that the developed theory represents the mechanical behaviour of a tread compound at room temperature very well. Thermomechanical heating effects, which are caused by inelastic deformations are also described by the theory. The method proposed in this paper can be utilised to generalise uniaxial rheological models to three-dimensional finite strain theories, which are admissible in the sense of the second law of thermodynamics.

Similar content being viewed by others

References

Lion, A.: A constitutive model for carbon black filled rubber: experimental investigations and mathematical representation. Continuum Mech. Thermodyn.6, 153–169 (1966).

Kilian, H. G., Strauss, M., Hamm, W.: Universal properties in filler loaded rubbers. Rubber Chem. Techn.67, 1–16 (1994).

Bueche, F.: Mullins-effect and rubber-filler interaction. J. Appl. Polym. Sci.5, 271–281 (1961).

Lubliner, J.: A model for rubber viscoelasticity. Mech. Res. Comm.12, 93–99 (1989).

Haupt, P.: On the thermodynamic representation of viscoplastic material behaviour. In: Proceedings of the ASME Materials Division Vol. 1 (MD-Vol. 69-1), pp. 503–515. The American Society of Mechanical Engineers 1995.

Haupt, P., Lion, A.: Experimental investigation and mathematical modeling of viscoplastic material behaviour. Continuum Mech. Thermodyn.7, 73–96 (1995).

Haupt, P., Tsakmakis, C.: On the application of dual variables in continuum mechanics. Continuum Mech. Thermodyn.1, 165–196 (1989).

Truesdell, C., Noll, W.: The nonlinear field theories of mechanics. Handbuch der Physik. Berlin: Springer 1965.

Valanis, K. C.: A Theory of viscoplasticity without a yield surface. Arch. Mech.23, 517–533 (1971).

Besdo, D.: Zur Beschreibung des Bauschinger Effektes im Dehnungsraum. ZAMM63, T144-T147 (1983).

Treloar, L. R. G.: The physics of rubber elasticity. London: Clarendon Press 1975.

Malmberg, T.: Thermodynamic consistency of viscoplastic material models involving external variable rates in the evolution equations for the internal variables. Bericht Nr. KfK 5193, Institut für Reaktorsicherheit, Kernforschungszentrum Karlsruhe, 1993.

Turner, D. M.: A triboelastic model for the mechanical behavior of rubber. Plastics Rubber Proc. Appl.9, 197–201 (1988).

Holownia, B. P., James, E. H.: Determination of dynamic bulk modulus of elastomers using pressure measurement. Rubber Chem. Technol. 749–753 (1993).

James, A. G., Green, A.: Strain energy functions of rubber, II. The characterization of filled vulcanisates. J. Appl. Polym. Sci.19, 2319–1330 (1975).

Flory, P. J.: Thermodynamic relations for high elastic materials. Trans. Faraday Society,57, 829–838 (1961).

Johnson, M. A., Beatty, M. F.: The Mullins-effects in uniaxial extension and its influence on the transverse vibration of a rubber string. Continuum Mech. Thermodyn.5, 83–115 (1993).

Johnson, M. A., Beatty, M. F.: A constitutive equation for the Mullins-effect in stress controlled uniaxial extension experiments. continuum Mech. Thermodyn.5, 301–318 (1993).

Krawietz, A.: Materialtheorie. Mathematische Beschreibung des phänomenologischen thermomechanischen Verhaltens. Berlin Heidelberg New York Tokyo: Springer 1986.

Haupt, P.: Thermodynamics of solids. CISM-Course Non-Equilibrium Thermodynamics with Application to Solids, Udine. Springer 1992.

Grosch, K. A.: Viskoelastische Eigenschaften von Gummimischungen und deren Einfluß auf das Verhalten von Reifen. Kautschuk Gummi Kunstst.42, 745–751 (1989).

Boyce, M. C., Parks, D. M., Argon, A. S.: Large inelastic deformation of glassy polymers. Part 1: rate dependent constitutive model. Mech. Mat.7, 15–33 (1988).

Miehe, C.: Zur numerischen Behandlung thermomechanischer Prozesse. Dr.-Ing. Thesis, Hannover, 1988.

Miehe, C.: Discontinuous and continuous damage evolution in Ogden-type large strain elastic materials. Eur. J. Mech. A Solids5, 697–720 (1995).

Miehe, C.: Entropic thermoelasticity at finite strains. Aspects of the formulation and numerical implementation. Comput. Methods Appl. Mech. Eng.120, 243–269 (1995).

Miehe, C.: Kanonische Modelle Finiter Elasto-Plastizität. Thermodynamische Formulierung und Numerische Implementation. Universität Hannover, Bericht-Nr. F 93/1, 1993.

Simo, J.: On a fully three-dimensional finite strain viscoelastic damage model: formulation and computational aspects. Comp. Meth. Appl. Mech. Eng.60, 153–173 (1987).

Govindjee, S., Simo, J.: A micro-mechanically based continuum damage model for carbon black-filled rubbers incorporating Mullins effect. J. Mech. Phys. Solids,39, 87–112 (1991).

Holzapfel, G.: Physikalische Modellierung und Finite Elemente Analyse von elastomeren Systemen unter Berücksichtigung von thermomechanisch gekoppelten Problemen. Habilitationsschrift TU Wien, 1995.

Holzapfel, G., Simo, J.: A new viscoelastic constitutive model for continuous media at finite thermomechanical changes. Int. Solids struct.33, 3019–3034 (1996).

Zimmerman, E.: Experimentelle Ermittlung und mathematische Modellierung der inelastischen Eigenschaften gummiartiger Werkstoffe unter eindimensionalen mechanischen Belastungen. Diplomarbeit, University of Kassel, Germany, 1995.

James, A. G., Green, A., Simpson, G. M.: Strain energy functions of rubber. I. Characterisation of gum vulcanizates. J. Appl. Polym. Sci.19, 2033–2058 (1975).

James, A. G., Green, A.: Strain energy functions of rubber. II. The characterization of filled vulcanisates. J. Appl. Polym. Sci.19, 2033–2058 (1975).

Christensen, R. M.: A nonlinear theory of viscoelasticity for application to elastomers. J. Appl. Mech.47, 762–768 (1980).

Browning, R., Gurtin, M. E., Williams, W. O.: A one-dimensional viscoplastic constitutive theory for filled polymers. Int. J. Solids Struct. 921–934 (1984).

Hausler, K., Sayir, M. B.: Nonlinear viscoelastic response of carbon black reinforced rubber derived from moderately large deformations in torsion. J. Mech. Solids43, 295–318 (1995).

Christensen, R. M.: A nonlinear theory of viscoelasticity for application to elastomers. J. Appl. Mech.4 7, 762–768 (1980).

Stickforth, J.: The rational mechanics and thermodynamics of polymeric fluids based upon a concept of a variable relaxed state. Rheol. Acta25, 447–458 (1986).

Haupt, P., Tsakmakis, Ch.: Stress tensors associated with deformation tensors via duality. Arch. Mech.48, 347–384 (1996).

Kamlah, M.: Zur Modellierung des Verfestigungsverhaltens von Materialien mit statischer Hysterese im Rahmen der phänomenologischen Thermomechanik. Dr.-Ing. Thesis, Kassel, 1994.

Kamlah, M., Bartling, H., Haupt, P.: Temperaturentwicklung im elastisch plastisch deformierten Zugstab. ZAMM75, T 193–194 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lion, A. A physically based method to represent the thermo-mechanical behaviour of elastomers. Acta Mechanica 123, 1–25 (1997). https://doi.org/10.1007/BF01178397

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01178397