Conclusions

-

1.

Within the limits of experimental error, the impact compressibility of different aluminum alloys in the test pressure range is weakly dependent on chemical composition, treatment process, and material strength.

-

2.

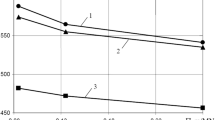

Resistance to deformation in the high strain rate region increases with increasing strain rate, and the boundary for a marked effect of strain rate on its resistance moves into the region of higher rates.

-

3.

In the case of the absence of a correlation between strength properties with uniaxial stress and uniaxial strain states, their sensitivity to loading rate may be connected with a single viscosity factor.

Similar content being viewed by others

Literature Cited

G. V. Stepanov, Elastoplastic Deformation of Materials Under the Influence of Shock Loads [in Russian], Naukova Dumka, Kiev (1979)

G. V. Stepanov and A. P. Vashchenko, “A specimen for impact testing material,” Inventor's Certificate, No. 796705, Byull. Izobret., No. 2 (1981).

G. V. Stepanov and V. V. Astanin, “Compressive impact testing of metals at high velocity,” Probl. Prochn., No. 2, 83–85 (1980).

C. H. Chiang, “High-speed tensile testing using high explosives,” J. Inst. Met., No. 3, 78–86 (1970).

G. I. Maiden and S. I. Green, “Compressive strain rate tests on six selected materials at strain rates from 10−3–104 in/in/sec,” Trans ASME, E, No. 3, 20–30 (1966).

T. Nicholas and J. D. Campbell, “Shear strain rate effects in a high-strength aluminum alloy,” Exp. Mech., No. 10, 441–447 (1972).

U. S. Lindholm, R. L. Bessey, and G. V. Smith, “Effect of strain on yield strength, tensile strength, and elongation of three aluminum alloys,” J. Mater., No. 1, 119–133 (1971).

L. V. Al'tshuler, “Use of shock waves in high-pressure physics,” Usp. Fiz. Nauk,85, No. 2, 199–207 (1965).

G. V. Stepanov and V. V. Astanin, “Impact compression of some structural materials at velocities up to 1000 m/sec,” Probl. Prochn., No. 9, 42–45 (1975).

V. V. Astanin, “Experimental study of shock compression of metals in elastoplastic loading waves with an intensity up to 10,000 MPa,” Zavod. Lab., No. 8, 754–758 (1980).

R. MacKooney, S. Marsh, J. Taylor, et al., An Equation of State for Solid Bodies from the Results of Studying Shock Waves. High-Speed Shock Phenomena [in Russian], Mir, Moscow (1973).

V. I. Romanchenko and G. V. Stepanov, “Dependence of critical stresses on time parameters for load during spalling in copper, aluminum, and steel,” Zh. Prikl. Mekh. Tekh. Fiz., No. 4, 141–145 (1980).

L. M. Barker and R. E. Hollenbach, “Shock waves studies of PMMA, fused silica, and sapphire,” J. Appl. Phys.,41, No. 10, 4208–4226 (1970).

A. N. Dremin and A. M. Molodets, “Two stages of the spalling failure process,” Dokl. Akad. Nauk SSSR,249, No. 6, 1361–1363 (1979).

Additional information

Institute of Strength Problems, Academy of Sciences of the Ukrainian SSR, Kiev, Moscow. Translated from Problemy Prochnosti, No. 2, pp. 59–63, February, 1983.

Rights and permissions

About this article

Cite this article

Stepanov, G.V., Astanin, V.V., Romanchenko, V.I. et al. Mechanical properties of a high-strength aluminum alloy with shock loading. Strength Mater 15, 220–225 (1983). https://doi.org/10.1007/BF01523474

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01523474