Abstract

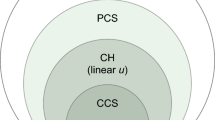

Among the many tasks designers must perform, evaluation of product options based on performance criteria is fundamental. Yet I have found that the methods commonly used remain controversial and uncertain among those who apply them. In this paper, I apply mathematical measurement theory to analyze and clarify common design methods. The methods can be analyzed to determine the level of information required and the quality of the answer provided. Most simple, a method using an ordinal scale only arranges options based on a performance objective. More complex, an interval scale also indicates the difference in performance provided. To construct an interval scale, the designer must provide two basic a priori items of information. First, a base-pointdesign is required from which the remaining designs are relatively measured. Second, the deviation of each remaining design is compared from the base point design using a metricdatum design. Given these two datums, any other design can be evaluated numerically. I show that concept selection charts operate with interval scales. After an interval scale, the next more complex scale is a ratio scale, where the objective has a well-defined zero value. I show that QFD methods operate with ratio scales. Of all measurement scales, the most complex are extensively measurable scales. Extensively measurable scales have a well defined base value, metric value and a concatenation operation for adding values. I show that standard optimization methods operate with extensively measurable scales. Finally, it is also possible to make evaluations with non-numeric scales. These may be more convenient, but are no more general.

Similar content being viewed by others

References

Y. Akao.Quality Function, Deployment: Integrating Customer Requirements into Product Design. Productivity Press, Cambridge, MA 1990.

M. Asimow.Introduction to Design. Prentice-Hall, Englewood Cliffs, NJ, 1962.

E. Bascaran, R. Bannerot and F. Mistree. Hierarchical selection decision support problems in conceptual design.Engineering Optimization, 14: 207–238, 1989.

P. Bernays.Axiomatic Set Theory. North-Holland, New York, 1968.

P. Biegel and M. Pecht. Design trade-offs made easy.Concurrent Engineering, 1(3): 29–40, May/June 1991.

M. Davis.Computability and Unsolvability. McGraw-Hill, New York, 1958.

D. C. Dlesk and J. S. Liebman. Multiple objective engineering optimization.Engineering Optimization, 6: 161–175, 1983.

H. Eschenauer, J. Koski and A. Osyczka (eds).Multicriteria Design Optimization. Springer-Verlag, Berlin, 1990.

T. Freiheit and S. S. Rao. A modified game theory approach to multi-objective optimization. In S. S. Rao (ed.),Advances in Design Automation — 1988, volume DE-14, pp. 107–114, New York, September 1988. ASME.

S. French.Decision Theory: An Introduction to the Mathematics of Rationality. Ellis Horwood, Chichester, 1988.

J. Hauser and D. Clausing. The house of quality.Harvard Business Review, pp. 63–73, May/June 1988.

B. Hayes.Measuring Customer Satisfaction: Development and Use of Questionnaires. ASQC Quality Press, Milwaukee, Wis., 1992.

R. Howard and J. Matheson (eds).The Principles and Applications of Decision Analysis. Strategic Decision Group, Menlo Park, CA, 1984.

D. Krantz, R. Luce, P. Suppes and A. Tversky.Foundations of Measurement, vol. I., Academic Press, New York, 1971.

E. Marsh, A. Slocum and K. Otto. Hierarchical decision making in mechanical design. Engineering Design Laboratory Technical Report 93-6, Massachusetts Institute of Technology, Cambridge, Mass., 1993.

F. Mistreeet al. Fuzzy compromise: An effective way to solve hierarchical design problems.Structural Optimization, 4: 115–120, 1992.

D. Nicklaus, S. Tong and C. Russo. Engineous: A knowledge directed computer aided design shell.Proceedings of the Third IEEE Conference on A1 Applications, February 1987.

K. N. Otto and E. K. Antonsson. Trade-Off Strategies in Engineering Design.Research in Engineering Design, 3(2): 87–104, 1991.

K. N. Otto and E. K. Antonsson. Modeling imprecision for product design. InProceedings of the 1994 FUZZ-IEEE Conference, pages 340–251. Orlando, FL, June 1994. IEEE.

K. N. Otto, A. D. Lewis and E. K. Antonsson. Determining optimal preference points with dependent variables.Fuzzy Sets and Systems, 60(1): 19–24, November 1993.

P. Papalambros and D. Wilde.Principles of Optimal Design. Cambridge University Press, New York, 1988.

S. Pugh.Total Design. Addison-Wesley, New York, 1990.

R. Putrus. Non-traditional approach in justifying computer integrated manufacturing systems. InAutofact '89 Conference Proceedings, pp. 8.1–8.26, Detroit, Mich., October 1989. SME.

H. Raiffa and R. Keeney.Decisions with Multiple Objectives: Preferences and Value Tradeoffs. Wiley, New York, 1976.

D. Rosen and J. Dixon. A methodology for conversions of feature-based representations. In L. Stauffer (ed.),Proceedings of the ASME Design Theory and Methodology Conference, pp. 45–51, Miami, 1991. ASME.

T. Saaty.The Analytic Hierarchy Process. McGraw-Hill, New York, 1980.

J. N. Siddall.Analytical Decision Making in Engineering Design. Prentice-Hall, Englewood Cliffs, NJ, 1972.

H. Simon.The Sciences of the Artificial. MIT Press, Cambridge, Mass., 2nd edn, 1981.

R. Steuer.Multiple Criteria Optimization: Theory, Computation, and Application. Wiley, New York, 1986.

D. Thurston. A formal method for subjective design evaluation with multiple attributes.Research in Engineering Design, 3(2): 105–122, 1991.

D. G. Ullman.The Mechanical Design Process. McGraw-Hill, New York, 1992.

K. Ulrich and S. Eppinger,Product Design and Development. McGraw-Hill, New York, 1995.

S. Vadde, R. Krishnamachi, F. Mistree and J. Allen. The bayesian compromise descision support problem for hierarchical design involving uncertainty. In G. Gabriele, editor,Advances in Design Automation, pp. 209–217. ASME, 1991. Vol. DE-32-1.

A. C. Ward and W. P. Seering. Extending the constraint propagation of intervals.Artificial Intelligence in Engineering Design and Manufacturing, 4(1): 47–51, 1990.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Otto, K.N. Measurement methods for product evaluation. Research in Engineering Design 7, 86–101 (1995). https://doi.org/10.1007/BF01606904

Issue Date:

DOI: https://doi.org/10.1007/BF01606904