Abstract

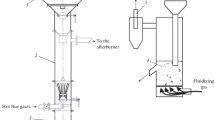

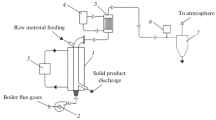

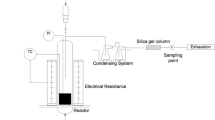

In order to perform biomass pyrolysis a continuous fluidized bed reactor (bench scale unit) has been assembled. The influence of experimental conditions such as heating-up time and optimum particle diameter is presented. By feeding the biomass (almond shells) directly into the bubbling bed, pyrolysis has been performed at temperatures ranging from 730° to 930°C at constant feed rate (44 g/h). Remarkable increase of H2 in the product gas is observed when steam rather than an inert carrier such as nitrogen is used thus confirming the potential of this approach.

Zusammenfassung

Zur Durchführung der Pyrolyse von Biomasse wurde ein kontinuierlicher Wirbelschichtreaktor gebaut. Es wird der Einfluß der Versuchsbedingungen wie z.B. Aufheizzeit und optimaler Partikeldurchmesser beschrieben. Wird die Biomasse (Mandelschalen) direkt in die Wirbelschicht eingeleitet, wurde die Pyrolyse bei Temperaturen zwischen 730° und 930°C bei einer konstanten Einspeisegeschwindigkeit von 44 gr/h) durchgeführt. Wird anstelle eines inerten Trägergases (z.B. Stickstoff) Wasserdampf verwendet, kann im Produktegas ein bemerkenswerter Anstieg von H2 verzeichnet werden, was die Leistungsfähigkeit dieser Näherung bestätigt.

Similar content being viewed by others

References

D. S. Scott and J. Piskorz, Can. J. Chem. Eng., 62 (1984) 405.

R. Graham, R. G. Bergougnou and R. P. Overend, J. Anal. Appl. Pyrol., 6 (1984) 363.

L. K. Mok, R. G. Graham, R. P. Overend, B. A. Freel and M. A. Bergougnou, BioEnergy 84; H. Egneus, A. Ellegard, Eds.; Elsevier, London 1985, p. 23.

J. Diebold, Proc. Specialists Workshop on Fast Pyrolysis of Biomass, SERI/CP622-1096, 1980, p. 237.

M. J. Antal, Jr. Adv. Solar Energy., 1 (1983a) 61.

J. L. Kuester, BioEnergy 84; H. Egneus, A. Ellegard, Eds.; Elsevier, London 1885, p. 48.

R. Font, A. Marcilla, J. Devesa and E. Verdu', Ind. Eng. Chem. Res., 27 (1988) 1143.

J. H. Perry, Chemical Engineering Handbook, Mc Graw Hill, 3rd Ed., New York 1973, p. 462.

R. Turton and O. Levenspiel., Fluidization VI Engineering Foundation, New York 1989, p. 669.

S. Rapagna', P. U. Foscolo, E. Tempesti and R. Di Felice Atti CISCI '91, Chianciano Terme 6–11 October 1991, p. 471.

S. Ergun, Chem. Eng. Prog., 48 (1952) 89.

P. U. Foscolo and L. G. Gibilaro, Chem. Eng. Sci., 39 (1984) 1667.

J. F. Richardson and W. N. Zaki, Trans. Inst. Chem. Engrs., 32 (1954) 35.

E. G. Baker, L. K. Mudge, M. D. Brown, Chem. Eng. Prog., 80 (1984) 43.

Author information

Authors and Affiliations

Additional information

The support of ENEA (Italian Agency for Renewable Energies) is gratefully acknowledged.

Rights and permissions

About this article

Cite this article

Rapagna, S., Tempesti, E., Foscolo, P.U. et al. Continuous fast pyrolysis of biomass at high temperature in a fluidized bed reactor. Journal of Thermal Analysis 38, 2621–2629 (1992). https://doi.org/10.1007/BF01979738

Issue Date:

DOI: https://doi.org/10.1007/BF01979738