Abstract

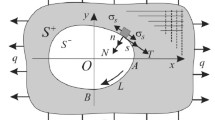

A new method has been developed that permits the direct design of shapes of two-dimensional structures, loaded in their plane, within specified design constrains and exhibiting optimum distribution of stresses. The method uses photoelasticity and requires a large-field diffused-light polariscope. The optimization process involves the removal of material (with a hand filer or router) from the low-stress portions of the hole boundary of the model till an isochromatic fringe coincides with the boundary both on the tensile and compressive segments.

The degree of optimization is evaluated by means of coefficient of efficiency

where\(\sigma _{a\ell \ell } \) represents the maximum allowable stress (the positive and negative superscripts referring to tensile and compressive stresses, respectively),S 0 andS 1 are the limiting points of the segment of boundary subjected to tensile stresses andS 1 andS 2 are the limiting points of the segment of boundary with compressive stresses.

Several problems of optimization related to the presence of holes in finite and infinite plates, subjected to uniaxial and biaxial loadings and in disks subjected to diametral loading, are solved parametrically. Some unexpected results have been found: (1) the optimum shape of a hole in a large plate, subjected to uniaxial load has a stress-concentration factor of 2.5 compared to 3 for the circular hole. The sides parallel to the load have a ‘barrel’ shape; (2) the optimum shape of a large hole in a narrow bar of finite width, subjected to uniaxial load, is ‘quasi’ square, but the transverse boundary has the configuration of a ‘hat’; (3) for the small hole in the large plate, under biaxial loading of equal and opposite sign, a double-barrel shape has a lower stress-concentration factor than the circular hole. In all these cases, there is appreciable saving in material. (4) The optimum, shape of a tube, subjected to diametral compression, has small ‘hinges’ and is much lighter and stronger than the circular tube. Fracture in a brittle material does not start at the hinge. Applications are also shown to the design of dove tails and slots in turbine blades and rotors, and to the design of star-shaped solid propellant grains for rockets, for both the case of parallel side rays and enlarged tip of rays. A parametric solution is given for this last case.

Similar content being viewed by others

References

Durelli, A.J., Brown, K. andYee, P., “Optimization of Geometric Discontinuities in Stress Fields,”Experimental Mechanics,18 (8),303–308 (1978).

Durelli, A.J., Rajaiah, K., Hovanesian, J.D. andHung, Y.Y., “General Method to Directly Design Stress-Wise Optimum Two-Dimensional Structures,”Mech. Res. Comm.,6(3),159–165 (1979).

Durelli, A.J. andRajaiah, K., “Optimized Inner Boundary Shapes in Circular Rings Under Diametral Compression,”Strain,15 (4),127–130 (Oct. 1979).

Durelli, A.J. and Rajaiah, K., “Quasi-Square Hole with Optimum Shape Subjected to Uniaxial Loading,” To be published in J. Mech. Design.

Durelli, A.J. andRajaiah, K., “Optimum Hole Shapes in Finite Plates Under Uniaxial Load,”J. Appl. Mech.,46,691–695 (Sept. 1979).

Peterson, R.E., “Stress Concentration Factors,” Wiley (1974).

Erickson, P.E. andRiley, W.F., “Minimizing Stress Concentrations Around Circular Holes in Uniaxially Loaded Plates,”Experimental Mechanics,18 (3),97–100 (1978).

Coker, E.G. and Filon, L.N.G., “A Treatise on Photoelasticity,” Cambridge University Press (1931).

Dhir, S.K. andBrock, J.S., “A New Method of Reinforcing a Hole Effecting Large Weight Savings,”Int. J. Solid Struct.,6,259–275 (1970).

Durelli, A.J. andMurray W.M., “Stress Distribution Around an Elliptical Discontinuity in any Two-dimensional, Uniform, and Axial System of Combined Stress,”Proc. Exp. Str. Analysis,1 (1),19–31 (1943).

Bjorkman, Jr., G.S. andRichards, Jr., R., “Harmonic Holes—an Inverse Problem in Elasticity,”J. Appl. Mech.,43,414–418 (1976).

Heywood, R.N., “Designing by Photoelasticity,” Chapman and Hall, 1952.

Heywood, R.N., “Photoelasticity for Designers,” Pergamon (1969).

Durelli, A.J. and Riley, W.F., “Introduction to Photomechanics,” Prentice Hall, 288 (1965).

Durelli, A.J., “Experimental Strain and Stress Analysis of Solid Propellant Rocket Motors,” Mech. and Chem. of Solid Propellants, Pergamon, 381–442 (1967).

Durelli, A.J., Dally, J.W. andRiley, W.F., “Stress and Strength Studies on Turbine Blade Attachments,”Proc. SESA,XVI (1),171–182 (Oct. 1957).

Durelli, A.J. Parks, V.J. andUribe, S., “Optimization of a Slot End Configuration in a Finite Plate Subjected to Uniformly Distributed Load,”J. Appl. Mech.,35,403–406 (1968).

Durelli, A.J., “Determination of Stresses on Free Boundaries by Means of Isostatics,” Proc. Fifteenth Semi-Annual Eastern Photoelasticity Conf. (June 20, 1942).

Durelli, A.J., Discussion of A. Francavilla, C.V. Ramakrishnan and O.C. Zienkievicz paper: “Optimization of Shape to Minimize Stress Concentration,” J. Strain Analysis,11 (3),191–192 (1976).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Durelli, A.J., Rajaiah, K. Lighter and stronger. Experimental Mechanics 20, 369–380 (1980). https://doi.org/10.1007/BF02321012

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02321012