Abstract

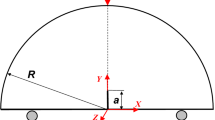

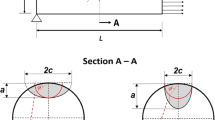

Dimensionless stress-intensity factors were determined for single-edge-crack solid and hollow round bars loaded in bending. These factors were calculated from experimental compliance (inverse slope of load-displacement curve) measurements made on round bars loaded in three-point bending. The compliance specimens had span to diameter ratios of 6.67 and 3.33, and measurements were made over a range of dimensionless crack lengths from 0.002 to 0.70. The tests were made using 3-in. (76-mm) and 6-in. (152-mm) solid and hollow round bars notched on one side; the hollow bars had an inner to outer diameter ratio of 0.33. A comparison was made with data in the literature for rectangular bars; for ana/D of 0.0001, the dimensionless stress-intensity factor for a solid round bar is 1.3 vs. 2.0 for a rectangular bar.

Similar content being viewed by others

Abbreviations

- a :

-

crack length or notch depth

- A :

-

area of cracked surface

- b :

-

coefficient-of-compliance curve-fitting equation

- B :

-

width of cracked front

- c :

-

compliance,v/P

- COD :

-

cracking-opening-displacement

- D :

-

diameter of round bar

- E :

-

Young's modulus, used 10.6×106 psi (73.1×103 MPa) for aluminum

- G :

-

energy-release rate

- I :

-

moment of inertia

- ID :

-

inner diameter of hollow round bar

- K I :

-

plane strain-stress intensity factor

- l :

-

one-half of the support span

- M :

-

bending moment

- μ:

-

Poisson's ratio, 0.32 for aluminum

- n :

-

exponent-of-compliance curve-fitting equation

- P :

-

load

- S :

-

support span of bend specimen

- σ:

-

stress

- SEC-RBB :

-

single-edge crack-round bend bar

- T :

-

thickness of rectangular bar

- U :

-

total strain energy of elastic deformation in specimen

- v :

-

displacement

- W :

-

width of rectangular bar

- Y′, Y :

-

dimensionless stress-intensity factors; the prime sign indicates a different form

References

Brown, W. F., Jr. and Srawley, J. E., “Plane Strain Crack Toughness Of High Strength Metallic Materials,” ASTM STP 410 (1966).

Bush, A. J. and Wilson, W. K., “Determination Of Energy Release Rate For Biaxial Brittle Fracture Specimen,” (Available from DDC as AD611659) (Aug. 1964).

Bluhm, J. I., “The Effects Of Non-Linear Hertzian Deformations And Of Gage Length On The Experimental Determination Of Elastic Energy Release Rate,” U.S. Army Materials Research Agency, Watertown, MA, ASTM E-24 Comm. Mtg. (June 1966).

Tada, H., Paris, P. C. and Irwin, G. R., “The Stress Analysis of Cracks Handbook,” Del Research Corporation, Appendix A (1973).

Standard Method Of Test For Plane Strain Fracture Of Metallic Materials,” E399-72, ASTM Standards, Part 31 (July 1972).

Federowicz, A. J. and Powell, B. A., “A Computer Program To Obtain Min-Max Regression Model By Linear Programming,” Westinghouse Research Report 68-1C3-COMP-R2 (July 1968).

Wilson, W. K., Private Communication, Westinghouse Research, Pgh., PA (April 1975).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bush, A.J. Experimentally determined stress-intensity factors for single-edge-crack round bars loaded in bending. Experimental Mechanics 16, 249–257 (1976). https://doi.org/10.1007/BF02321148

Issue Date:

DOI: https://doi.org/10.1007/BF02321148