Abstract

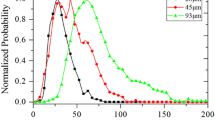

The dependence of RMS acoustic-emission output on strain rate was determined during tensile tests on 7075-T6 aluminum over a range of strain rates from 0.015 min−1 to 0.230 min−1. A special normalization technique was developed to eliminate the inherent differences in the acoustic emission from supposedly identical specimens tested under identical conditions. It was found that the RMS acoustic-emission output increases approximately linearly with strain rate, and that the slope of the linear dependence decreased with increased plastic strain. The effect of pinned dislocation breakaway on the acoustic-emission output vs. plastic-strain relationship is the subject of a preliminary theory.

Similar content being viewed by others

Abbreviations

- A :

-

constant

- B :

-

constant

- H :

-

hardening coefficient

- L i :

-

pinned-dislocation length per unit volume

- n i :

-

number of dislocation segments

- n :

-

constant

- RMS :

-

acoustic-emission voltage output

- t :

-

time

- \(\dot \in \) :

-

strain rate

- ∈ p :

-

plastic-strain rate

- \(\dot \in _p \) :

-

plastic-strain rate

- ρ t :

-

total-dislocation density per unit volume

- ρ m :

-

mobile-dislocation density per unit volume

- ρ m′ :

-

mobile-dislocation density per unit volume associated with unpinning

- \(\mathop \Sigma \limits_{i = 1} \) :

-

summation overi

- σ i :

-

root-mean-square shear stress

- v :

-

crosshead rate

References

James, D. R. andCarpenter, S. H., “Relationship Between Acoustic Emission and Dislocation Kinetics in Crystalline Solids,”J. of Appl. Phys.,42 (12),4685 (1971).

Frederick, J. R., “Dislocation Motion as a Source of Acoustic Emission”, Acoustic Emission, STP 505, edited by R. G. Liptai, D. O. Harris and C. A. Tatro, ASTM (1972).

Gillis, “Dislocation Motions and Acoustic Emission,” Acoustic Emission, STP 505, edited by R. G. Liptai, D. O. Harris and C. A. Tatro, ASTM (1972).

Dunegan, H. L. andHarris, D. O., “Acoustic Emission—A New Nondestructive Testing Tool,”Ultrasonics,1,160, (1967).

Schofield, B. H., “Acoustic Emission Under Applied Stress,” AF Materials Lab., Wright-Patterson AFB, Oh, Contract No. AF 33 (657)-8562, Project No. 7360, Task No. 736002, Tech. Documentary Report No. ASD-TDR-509, Part II (May 1964).

Fisher, R. M. andLally, J. S., “Microplasticity Detected by an Acoustic Technique,”Can. J. Phys.,45,1147 (1967).

Dunegan, H. L., Harris, D. O. andTatro, C. A., “Fracture Analysis By Use of Acoustic Emission,”Engn. Fract. Mech.,1,105 (1968).

Tatro, C. A., “Design Criteria For Acoustic Emission Experimentation”, Acoustic Emission, STP 505, edited by R. G. Liptai, D. O. Harris and C. A. Tatro, ASTM (1972).

Bill, R. C., “An Acoustic Emission Study Of The Deformation Mechanics of Polycrystalline Aluminum and Copper,”PhD Dissertation, Univ. of Michigan, Ann Arbor, MI (1970).

Mukherjee, A. K., unpublished work, Univ. of California, Davis, CA.

Koehler, J. S., Imperfections in Nearly Perfect Crystals, John Wiley and Sons, New York Ch. 7 (1952).

Mason, W. P., “Phonon Viscosity and Its Effect on Acoustic Wave Attenuation and Dislocation Motion,”J. of the ASA,32 (4),458 (1960).

Sedwick, R. T., “Acoustic Emission From Single Crystals of LiF and KCI,”J. of Appl. Phys.,39 (1),1728 (1968).

James, D. R., Short Course, “Acoustic Emission Technology,”Dunegan Research Corporation, Livermore, CA (Aug. 1972).

Gilman, J. J., “Microdynamical Theory of Plasticity,”Microplasticity Edited by C. J. McMahon, Jr., Interscience, New York 17 (1968).

Kahn, D., Austin, D., Mukherjee, A. K. and Dorn, J. E., “The Importance of Geometric Statistics to Dislocation Motion,” J. of Appl. Probability, in press.

Gerberich, W. andReuter, W., Final Report to ONR, Contract No. 00014-66-C0340, Aerojet-Genetal Corporation, Sacramento, CA (1969).

Conrad, H., Dislocation Dynamics, edited by A. R. Rosenfield, J. T. Hahn, A. L. Bement andR. I. Jaffee, McGraw-Hill Book Co., New York, 431 (1968).

Author information

Authors and Affiliations

Additional information

Work was performed under the auspices of the U.S. Atomic Energy Commission.

Rights and permissions

About this article

Cite this article

Hamstad, M.A., Mukherjee, A.K. The dependence of acoustic emission on strain rate in 7075-T6 aluminum. Experimental Mechanics 14, 33–41 (1974). https://doi.org/10.1007/BF02324858

Issue Date:

DOI: https://doi.org/10.1007/BF02324858