Abstract

Various compression test methods for composite materials have been developed during the past few years incorporating specimens of different gage lengths and modes of load introduction. Most of these test methods are not recognized as standards at the present time. Thus the question arises as to whether these various test methods produce similar results.

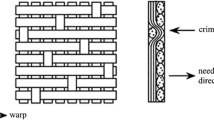

Two commonly used test fixtures are compared in detail here, viz., the ASTM Standard D 3410 IITRI compression test fixture, and another often referred to as the Boeing-Modified D 695 compression test fixture. The IITRI fixture loads a specimen of 12.7-mm gage length via shear through end tabs and wedge grips. The Boeing-Modified D 695 fixture also uses a tabbed specimen, but with only a 4.8-mm gage length and loaded directly on its ends.

Hercules S2/3501-6 glass/epoxy and AS4/3501-6 carbon/epoxy unidirectional composites were used as the primary material configurations in the present comparison. Highstrength, highly orthotropic materials such as these are among the most difficult composites to test successfully in compression. However, a carbon/epoxy quasi-isotropic laminate was tested as well.

The results obtained are compared with similar data available in the literature. It is concluded that there is relatively little influence of specimen gage length as long as it is sufficiently small so that gross buckling does not occur. Also, the differences between shear loading and end loading of the specimen are small, as long as the ends of the end-loaded specimen do not crush, and that in either case the tabs do not debond.

Similar content being viewed by others

References

Popov, E.P., Mechanics of Materials, 2nd Ed., Prentice-Hall, Inc., Englewood Cliffs, NJ, 461–500 (1976).

“Compressive Properties of Unidirectional or Crassply Fiber-Resin Composites,” ASTM Standard D 3410-87, Amer. Soc. Test. and Mat. Philadelphia (1975).

Westberg, R.L. andAbdallah, M.G., “An Experimental and Analytical Evaluation of Three Compressive Test Methods for Unidirectional Graphite/Epoxy Composites,”Rep. RI-86B12100, Hercules, Inc., Magna, UT (May 12, 1987).

Berg, J.S. and Adams, D.F., “An Evaluation of Composite Material Compression Test Methods,” Rep. UW-CMRG-R-88-106, Comp. Mat. Res. Group, Univ. of Wyoming (June 1988).

“Price List and Specifications Brochures: Composite Material Mechanical Test Fixtures,” Wyoming Test Fixtures, Inc., Laramie, WY (May 1989).

Port, K.F., “The Compressive Strength of Carbon Fibre Reinforced Plastics,”Tech. Rep. 82083, Roy. Aircraft Est., Farnborough, Hants, UK (Aug. 1982).

“Compressive Properties of Rigid Plastics,” ASTM Standard D 695-85, Amer. Soc. Test. and Mat., Philadelphia (1942).

“SACMA Recommended Test Method for Compressive Properties of Oriented Fiber-Resin Composites,” Recommended Method SRM 1-88, Suppliers of Advanced Composite Materials Association, Washington, DC (1989).

Bogetti, T.A., Gillespie, J.W., Jr. andPipes, R.B., “Evaluation of the IITRI Compression Test Method for Stiffness and Strength Determination,”Comp. Sci. and Tech.,32 (1),57–76 (1988).

Berg, J.S. andAdams, D.F., “An Evaluation of Composite Material Compression Test Methods,”J. Comp. Tech. and Res.,11 (2),41–46 (Summer 1989).

Abdallah, M.G., “State of the Art of Advanced Composite Materials: Compression Test Methods,” JANNAF, CMCS and SAMS Joint Meeting, Jet Propulsion Lab., Pasadena, CA (Nov. 1984).

Camponeschi, E.T., Jr., “Compression of Composite Materials: A Review,”Report No. DTRC-87/050, David Taylor Res. Ctr., Bethesda, MD (Nov. 1987).

Hancox, N.L., “The Compression Strength of Unidirectional Carbon Fibre Reinforced Plastic,”J. Mat. Sci.,10 (2),234–242 (Feb. 1973).

Smoot, M.A., “Compressive Response of Hercules AS1/3501-6 Graphite/Epoxy Composites,” Report CCM-82-16, Center for Comp. Mat., Univ. of Delaware (June 1982).

Barker, A.J. andBalasundaram, V., “Compression Testing of Carbon Fibre-Reinforced Plastics Exposed to Humid Environments,”Composites,18 (3),217–226 (July 1987).

Timoshenko, S.P. andGere, J.M., Theory of Elastic Stability, 2nd Ed., McGraw-Hill Book Co., New York, 132–135 (1961).

Coguill, S.L. and Adams, D.F., “Mechanical Properties of Several Neat Polymer Matrix Materials and Unidirectional Carbon Fiber-Reinforced Composites,” Rep. UW-CMRG-R-89-114, NASA Contractor Rep. 181805, Dept. of Mech. Eng., Univ. of Wyoming (April 1989).

“Hercules AS4/3501-6 Carbon/Epoxy and S2/3501-6 Glass/Epoxy Composite Material Specifications,” Hercules, Inc., Magna, UT (1989).

Adams, D.F. and Odom, E.M., “Influence of Specimen Tabs on the Compressive Strength of a Unidirectional Composite Material,” J. Comp. Mat.,25 (3), (March 1991).

“Techkits A-12 Epoxy Adhesive,” Techkits, Inc., Demarest, NJ (1989).

Rehfield, L.W., Armanios, E.A. andChangli, Q., “Analysis of Behavior of Fibrous Composite Compression Specimens,”Recent Advances in Composites in the United States and Japan, ASTM STP 864, ed. J.R. Vinson andM. Taya, Amer. Soc. Test. and Mat., Philadelphia, 236–252 (1985).

Hofer, K.E., Jr. andRao, P.N., “A New Static Compression Fixture for Advanced Composite Materials,”J. Test. and Eval.,5 (4),278–283 (July 1977).

Adsit, N.R., “Compression Testing of Graphite/Epoxy,” Compression Testing of Homogeneous Materials and Composites, ASTM STP 808, ed. R. Chait and R. Papirno, Amer. Soc. Test. and Mat., 175–186 (1983).

Adams, D.F., “A Comparison of Composite Material Compression Test Methods in Current Use,” Proc. 34th Int. SAMPE Symp., Reno, NV, 1422–1433 (May 1989).

Woolstencroft, D.H., Curtis, A.R. andHaresceugh, R.J., “A Comparison of Test Techniques Used for the Evaluation of the Unidirectional Compressive Strength of Carbon Fibre-Reinforced Plastic,”Composites,2 (4),275–280 (Oct. 1981).

Adams, D.F. and Odom, E.M., “Influence of Test Fixture Configuration on the Measured Compressive Strength of a Composite Material,”J. Comp. Tech. and Res.,13 (1), (Spring 1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Adams, D.F., Lewis, E.Q. Influence of specimen gage length and loading method on the axial compressive strength of a unidirectional composite material. Experimental Mechanics 31, 14–20 (1991). https://doi.org/10.1007/BF02325717

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02325717