Abstract

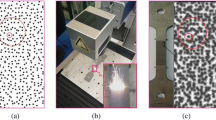

Laser-speckle-pattern correlation is used for the determination of elastic-plastic boundary on the surface of well polished metal specimens. The method employs a converging laser beam to illuminate the test object. Diffracted verging laser beam to illuminate the test object. Diffracted images are recorded and processed on a computer-based vision system. Subsequent image-correlation analysis yields information on the surface deformation of the test objects. The technique is applied to a flat tensile specimen with two circular notches at the central portion. Measured plastic zone is compared with results obtained by the finite-element method.

Similar content being viewed by others

References

Burch, J.M. andTokarski, J.M.J., “Production of Multi Beam Fringes from Photographic Scatters,”Opt. Acta,15 (2),101 (1968).

Archbold, E., Burch, J.M. andEnnos, A.E., “Recording of Inplane Surface Displacement by Double Exposure Speckle Photography,”Opt. Acta,17 (12),883 (1970).

Chiang, F.P., “Speckle Metrology,”Metals Handbook, 9th Ed., Vol. 17 Nondestructive Evaluation and Quality Control, ASM International Metals Park, OH (1989).

Stetson, K.A., “Speckle Photography and Interferometry: A Review,”Opt. Eng.,14,482 (1975).

Thomson, P.F. andShafer, B.V., “The Roughening of Free Surface During Plastic Working,”Int. J. Mach. Tool Des. Res.,22 (4),261–264 (1982).

Yamaguchi, K. andMellor, P.B., “Thickness and Grain Size Dependence of Limit Strains in Sheet Metal Stretching,”Int. J. Mech. Sci.,18,85–90 (1976).

Sigler, D. and Haworth, W.L., “Strain Measurement by Optical Correlation,” J. Nondest. Eval.,2 (2), (1981).

Miyagawa, M. and Azushima, A., “Measurement of Plastic Deformation by Means of a Laser Beam,” 9th World Conf. on Nondestructive Testing, Session 4a-4, Melbourne, Australia (Nov. 1979).

Denby, D. andLeendertz, J.A., “Plane-Surface Strain Examination by Speckle-Pattern Interferometry using Electronic Processing,”J. Strain Analysis,9 (1),17–25 (1974).

Lee, C., Chao, Y.J., Peters, W.H. and Sutton, M.A., “Surface Texture and Plastic Deformation,” Proc. 13th Southeastern Conf. on Theor. and Appl. Mech., Session 17c-4, USA (1986).

Lee, C., Chao, Y.J., Sutton, M.A., Peters, W.H. andRanson, W.F., “Determination of Plastic Strains at Notches by Image-Processing Methods,”Experimental Mechanics,29 (2),214–220 (1989).

Maron, E., “Real-Time Strain Measurements by Optical Correlatioon,”App. Opt.,9 (6),1385–1391 (1970).

Rosenfeld, A. and Kak, C.A., Digital Picture Processing, Academic Press (1982).

Chiang, F.P., Tay, C.J. and Dai, Y.Z., “Determination of Elastic-Plastic Boundary by Speckle Pattern Correlation,” Proc. 4th Int. Symp. Nondestructive Characterization of Materials,” Annapolis, MD (June 11–14, 1990).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dai, Y.Z., Tay, C.J. & Chiang, F.P. Determination of the plastic zone by laser-speckle correlation. Experimental Mechanics 31, 348–352 (1991). https://doi.org/10.1007/BF02325992

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02325992