Abstract

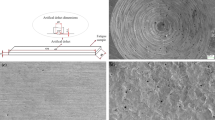

A study has been made of the effects of shot peening and fatigue cycling on the residual macrostresses determined by X-ray methods in an austenitized and tempered AISI 4130 steel (150–170 ksi). The results show that the effect of shot peening is to produce a residual compressive macrostress layer 0.014-in. deep. The residual-stress profile (stress vs. depth) exhibits a small negative stress gradient at and near the surface and a large positive stress gradient in the interior. Stress relaxation (due to fatique cycling) which occurred early in the fatigue history of the specimen was found greater at the surface than in the subsurface layers. Stress gradients of the stress profile increased with continued cycling and varied with depth. A correlation appears to exist between stress relaxation and stress gradients at the surface.

Similar content being viewed by others

References

Dolan, T. J., “Residual Stress, Strain Hardening and Fatigue,”Internal Stresses and Fatigue in Metals, G. M. Rassweiler andW. L. Grube, eds., Elsevier Publishing Corp., New York, 264–310 (1959).

Mattson, R. L., andRoberts, J. G., “The Effect of Residual Stresses Induced by Strain Peening Upon Fatigue Strength,”,337–360 (1959).

Grover, H. J., Gordon, S. A., and Jackson, L. R., Fatique of Metals and Structures, Washington, D. C., Bureau of Naval Weapons, Dept. of the Navy, 102–105 (Rev. ed. 1960).

Coombs, A. G. H., et al., “An Analysis of the Effects of Shot-Peening Upon the Fatigue Strength of Hardened and Tempered Spring Steel,” International Conference on Fatique of Metals, Inst. Mech. Engrs., 227–234 (1956).

Mattson, R. L., “Fatigue, Residual Stresses and Surface Cold Working,” International Conference on Fatique of Metals, Inst. Mech. Engrs., 593–603 (1956).

Taira, S., and Murakami, Y., “Effect of Residual Stresses on Fatigue Strength,” Proc. 5th Japan Congress on Testing Materials, 27–31 (1962).

Hempel, M. R., “Surface Condition and Fatigue Strength,” Internal Stresses and Fatique in Metals, 311–336 (see Ref. 1).

Evans, W. P., andBuenneke, R. W., “X-Ray Broadening of Hardened and Coldworked Steel,”Trans. AIME,227,447–451 (1963).

Morrow, J., and Millan, J. F., “Influence of Residual Stresses on Falique of Steel,” SAE TR-198, 4–6 (1961).

Honeycombe, R. W. K., “Session on Fatigue and Ductile Fracture,”Fracture ed. by B. L. Averbach, D. K. Felbeck andG. T. Hahn, MIT Press, Cambridge, Mass., 9–14 (1959).

Morrow, J., Ross, A. S., andSinclair, G. M., “Relaxation of Residual Stresses Due to Fatigue Loading,”SAE Trans.,68,40–48 (1960).

Taira, S., and Murakami, Y., “On the Changes in Residual Stresses Due to Repeated Stressing,” Proc. 3rd Japan Congress on Testing Materials, 52–55 (1960).

Uhlig, H. H., “New Prespectives in the Stress Corrosion Problem,”Physical Metallurgy of Stress Corrosion Fracture, T. N. Rhodin, ed., Interscience Publishers, Inc., New York, 1–17 (1959).

Suss, H., “Shot Peening of Metals for Protection Against Stress Corrosion Cracking,”Corrosion,18,17t-20t (1962).

Soffa, L. L., “Stress Corrosion and Stress Rupture Tests of 2½ Inch 7075-T6 Aluminum Alloy Rolled Plate,” Northrop Aircraft, Inc., Report No. NAI-56-701 (MPR 705513) (Sept. 10, 1956).

Cullity, B. D., Elements of X-Ray Diffraction, Addison-Wesley Publishing Co., Inc., Reading, Mass., 446 (1959).

Koistinen, D. P., andMarburger, R. E., “A Simplified Procedure for Calculating Peak Position in X-Ray Residual Stress Measurements on Hardened Steel,”Trans. ASM,51,537 (1959).

Christenson, A. L., et al., ed., “The Measurement of Stress by X-Ray,” SAE TR-182 (1960).

Moore, M. G., andEvans, W. P., “Mathematical Correction for Stress in Removed Layers in X-Ray Diffraction Residual Stress Analysis,”SAE Trans.,66,340–345 (1958).

Woehrle, H. R., et al., “Experimental X-Ray Stress Analysis Procedures for Ultrahigh-Strength Materials,” Advances in X-Ray Analysis, 38–47 (1965).

Bolstad, D. A., andQuist, W. E., “The Use of a Portable X-Ray Unit for Measuring Residual Stresses in Aluminum, Titanium and Steel Alloys,”Advances in X-Ray Analysis,8,26–37 (1965).

Esquivel, A. L., and Bolstad, D. A., “X-Ray Diffraction Study of the Effects of Plastic Deformation on Residual Stress Measurements,” Boeing Document D6-15798TN (1967).

Hilley, M. E., Wert, J. J., andGoodrich, R. S., “Experimental Factors Concerning X-Ray Residual Stress Measurements in High Strength Aluminum Alloys,”Advances in X-Ray Analysis,10,284–294 (1967).

Wei, R. P., andBaker, A. J., “A Metallographic Study of Iron Fatigued in Cyclic Strain at Room Temperature,”Phil. Mag.,12,1005–1020 (1965).

Morrow, J., and Sinclair, G. M., “Cycle Dependent Stress Relaxation,” Symposium on Basic Mechanisms of Fatigue ASTM STP-237, 83–109 (1959).

Evans, W. P., and Millan, J. F., “Effect of Microstrains and Particle Size on the Fatigue Properties of Steel,” SAE TR-793B, 1–9 (1964).

Hargreaves, M. E., Loretto, M. H., Clarebroguh, L. M., andSegall, R. L., “Recovery after Unidirectional and Reverse Straining in Copper,”The Relation Between the Structure and Mechanical Properties of Metals, Her Majesty's Stationery Office, London, 209–215 (1963).

Kennedy, A. J., Processes of Creep and Fatigue in Metals, New York, J. Wiley, 293 (1962).

Author information

Authors and Affiliations

Additional information

K. R. Evans was Research Engineer at the Boeing Company when paper was prepared; is now at Shell Development Co., Emeryville, Calif.

Rights and permissions

About this article

Cite this article

Esquivel, A.L., Evans, K.R. X-ray diffraction study of residual macrostresses in shot-peened and fatiqued 4130 steel. Experimental Mechanics 8, 496–503 (1968). https://doi.org/10.1007/BF02327126

Issue Date:

DOI: https://doi.org/10.1007/BF02327126