Abstract

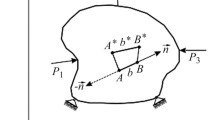

A simple system has been developed to measure surface strains that occur during in situ deformation of mechanical test specimens. The system uses photolithographically deposited displacement markers and computer image recognition routines to determine in-plane displacements and strains from digital images. The strain calculating routines are integrated into a simple mouse-driven software package that facilitates the transformation from digital images to useful strain field information. Additional routines have been developed to determine crack tip stress fields and J integrals. Crack tip stress intensities have been calculated from strain maps obtained for traction-free cracks in stainless steel. The J integrals were found to be independent of contour and consistent with applied stress intensities. Crack tip stress intensities were calculated for bridged cracks in lamellar TiAl. The toughening effect of the bridging zones was determined by including the bridged region in the contours. Resistance curves generated from strain maps were consistent with those measured during mechanical testing.

Similar content being viewed by others

References

Post, D., “Developments in Moiré Interferometry,”Optical Eng.,21 (3),458–467 (1982).

Han, B. andPost, D., “Immersion Interferometer for Microscopic Moiré Interferometry,”Experimental Mechanics,32 (2),38–43 (1992).

Cox, B.N., Morris, W.L. and James, M.R., “High Sensitivity, High Spatial Resolution Strain Measurements in Composites and Alloys,” Proc. Nondestructive Testing and Eval. of Adv. Mat. and Composites, Colorado Springs, CO, 25–39 (1986).

James, M.R., Morris, W.L., Cox, B.N. andDadkhah, M.S., “Description and Application of Displacement Measurements Based on Digital Image Processing,”Micromechanics: Experimental Techniques, ASTM AMD vol. 102, 89–100 (1989).

Davidson, D.L., Chan, K.S. andPage, R.A., “Automated High-Resolution Displacement Measurements Based on Digital Image Processing,” Micromechanics: Experimental Techniques, ASTM AMD vol. 102, 73–88 (1989).

Han, G., Sutton, M.A. andChao, Y.J., “A Study of Stationary Crack Tip Fields in Thin Sheets by Computer Vision,”Experimental Mechanics,34 (3),125–139 (1994).

Fail, R.W. andTaylor, C.E., “An Application of Pattern Mapping to Plane Motion,”Experimental Mechanics,30 (4),404–410 (1990).

Bradley, W.L., “Fracture Toughness of Polymer Matrices in Relation to Interlaminar Fracture Toughness,”Application of Fracture Mechanics to Composite Materials, ed. K. Friedrich, Elsevier North-Holland, New York, 156–187 (1990).

Sirkis, J.S. andLim, T.J., “Displacement and Strain Measurement with Automated Grid Methods,”Experimental Mechanics,31 (4),382–388 (1991).

Joshi, R.B., Bayoumi, A.E. andZbib, H.M., “The Use of Digital Processing in Studying Stretch-Forming Sheet Metal,”Experimental Mechanics,32 (2),117–123 (1992).

Hatanaka, K., Fujimitsu, T. andInoue, H., “A Measurement of Three-Dimensional Strains around a Crack Tip,”Experimental Mechanics 32 (3),211–218 (1992).

Hall, E.L., Computer Image Processing and Recognition, Academic Press, New York, 186 (1979).

Timoshenko, S.P. andGoodier, J.N., Theory of Elasticity, McGraw-Hill, New York, 6 (1951).

Malvern, L.E., Introduction to the Mechanics of a Continuous Medium, Prentice Hall, Englewood Cliffs, NJ, 160 (1969).

Rice, J.R., “A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks,”ASME J. Appl. Mech. 35,379–386 (1968).

Dadkhah, M.S., Kobayashi, A.S. andMorris, W.L., “Crack-Tip displacement Fields and J R Curves of Four Aluminum Alloys,”ASTM STP 1131, 135–153 (1992).

Hutchinson, J.W., “Singular Behavior at the End of a Tensile Crack in a Hardening Material,”J. Mech. and Phys. Solids,16,13–27 (1968).

Rice, J.R. andRosengren, G.F., “Plane Strain Deformation Near a Crack Tip in a Power Law Hardening Material,”J. Mech. and Phys. Solids,16,1–12 (1968).

Wissuchek, D.J., unpublished work.

Shih, C.F., “Small-Scale Yielding Analysis of Mixed Mode Plane Strain Crack Problems,” Fracture Analysis, ASTM STP 560, American Society for Testing and Materials, 187–210 (1974).

Deve, H.E., Evans, A.G. andShih, D.S., “A High Toughness Gamma Titanium Aluminide,”Acta Metall.,40,1259–1265 (1992).

Chan, K.S., “Toughening Mechanisms in Titanium Aluminides,”Metall. Trans. A,24A,569–583 (1993).

Chan, K.S. andKim, Y.-W., “Relationships of Slip Morphology, Microcracking, and Fracture Resistance in a Lamellar TiAl-Alloy,”Metall. Trans. A,25A,1217–1228 (1994).

Kim, Y.W., “Microstructural Evolution and Mechanical Properties of a Forged Gamma Titanium Aluminide Alloy,”Acta Metall. Mater.,40,1121–1133 (1992).

Wissuchek, D.J., submitted to Metall. Trans. A.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wissuchek, D.J., Mackin, T.J., De Graef, M. et al. A simple method for measuring surface strains around cracks. Experimental Mechanics 36, 173–179 (1996). https://doi.org/10.1007/BF02328715

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02328715