Abstract

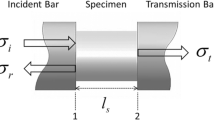

The upper limit of the achievable constant strain rates in linearly elastic specimens loaded by a split Hopkinson pressure bar is estimated based on the specimen properties and a linear ramp loading. The criterion for a plateau of constant strain rate is derived and discussed. Dynamic experimental results on an S-2 glass/SC15 composite and polymethyl-methacrylate subjected to various ramp loadings verify the modeling results.

Similar content being viewed by others

References

Kolsky, H., “An Investigation of the Mechanical Properties of Materials at Very High Rates of Loading,”Proceedings of the Royal Society of London B,62,676–700 (1949).

Gary, G.T., Classic Split-Hopkinson Pressure Bar Testing,”Mechanical Testing and Evaluation, Metals Handbook, American Society for Metals, Materials Park, OH, Vol. 8, 462–476 (2000).

Nicholas, T., “Material Behavior at High Strain Rates,”Impact Dynamics, Wiley, New York, 277–332 (1982).

Follansbee, P.S., “The Hopkinson Bar,” Mechanical Testing, Metals Handbook, 9th Edn, American Society for Metals, Metal Park, OH, Vol. 8, 198–203 (1985).

Frew, D.J., Forrestal, M.J., andChen, W., “A Split Hopkinson Pressure Bar Technique to Determine Compressive Stress-strain Data for Rock Materials, EXPERIMENTAL MECHANICS,41,40–46 (2001).

Frew, D.J., Forrestal, M.J., andChen, W., “Pulse Shaping Techniques for Testing Brittle Materials with a Split Hopkinson Pressure Bar,” EXPERIMENTAL MECHANICS,42,93–106 (2002).

Thiruppukuzhi, S.V. andSun, C.T., “Models for the Strain-rate-dependent Behavior of Polymer Composites,”Composites Science and Technology,61,1–12 (2001).

Tsai, J. andSun, C.T., “Constitutive Model for High Strain Rate Response of Polymeric Composites”Composites Science and Technology,62,1289–1297 (2002).

Chen, W., Lu, F.Y., andCheng, M., “Tension and Compression Tests of Two Polymers under Quasi-static and Dynamic Loading,”Polymer Testing,21,113–121 (2002).

Ochola, R.O., Marcus, K., Nurick, G.N., andFranz, T., “Mechanical Behavior of Glass and Carbon Fiber Reinforced Composites at Varying Strain Rates,”Composite Structure,63,455–467 (2004).

Song, B., Chen, W., andWeerasooriya, T., “Quasi-static and Dynamic Compressive Behaviors of an S-2 Glass/SC15 Composite,”Journal of Composite Materials,37,1723–1743 (2003).

Chen, W., Song, B., Frew, D.J., andForrestal, M.J., “Technical Note: Dynamic Small Strain Measurements of a Metal Specimen with a Split Hopkinson Pressure Bar,” EEXPERIMENTAL MECHANICS,43,20–23 (2003).

Ravichandran, G. and Subhash, G., “Critical Appraisal of Limiting Strain Rates for Compression Testing of Ceramics in a Split Hopkinson Pressure Bar” Journal of the American Ceramic Society,77 (1994).

Chen, W. andRavichandran, G., “Dynamic Compressive Failure of a Glass Ceramic under Lateral Confinement,”Journal of the Mechanics and Physics of Solids,45,1303–1328 (1997).

Gray, G.T. III, Blumenthal, W.R., Trujillo, C.P., andCarpenter, R.W. II, “Influence of Temperature and Strain Rate on the Mechanical Behavior of Adiprence L-100,”Journal de Physique IV France Colloq. C3 (DYMAT 97),7,523–528 (1997).

Song, B. andChen, W., “Dynamic Stress Equilibrium in Split Hopkinson Pressure Bar Tests on Soft Materials,” EXPERIMENTAL MECHANICS,44,300–312 (2004).

Holt, D.L., “The Modulus and Yield Stress of Glassy Poly(Methyl Methacrylate) at Strain Rates up to 10 3 Inch/Inch/Second,”Journal of Applied Polymer Science,12,1653–1659 (1968).

Hasan, O.A. andBoyce, M.C., “A Constitutive Model for the Nonlinear Viscoelastic Viscoplastic Behavior of Glassy Polymers,”Polymer Engineering and Science,35 (4).331–344 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pan, Y., Chen, W. & Song, B. Upper limit of constant strain rates in a split Hopkinson pressure bar experiment with elastic specimens. Experimental Mechanics 45, 440–446 (2005). https://doi.org/10.1007/BF02427992

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02427992