Abstract

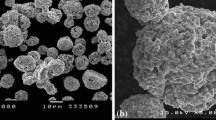

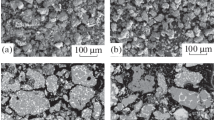

The structure, hardness, and shear adhesion strength have been investigated for Cr3C2-NiCr cermet coatings sprayed onto a mild steel substrate by 200 kW high power plasma spraying (HPS) and high velocity oxy-fuel (HVOF) processes. Amorphous and supersaturated nickel phases form in both as-sprayed coatings. The hardness of the HVOF coating is higher than that of the HPS coating, because the HVOF coating contains more nonmelted Cr3C2 carbide particles. On heat treating at 873 K, the amorphous phase decomposes and the supersaturated nickel phase precipitates Cr3C2 carbides so that the hardness increases in the HPS coating.

The hardness measured under a great load exhibits lower values compared with that measured with a small load because of cracks generated from the indentation. The ratio of the hardnesses measured with different loads can be regarded as an index indicating the coating ductility. The ductility of the HVOF coating is higher than that of the HPS coating. Adhesion strength of the HVOF coating was high compared with the HPS coating. The adhesion of the coatings is enhanced by heat treating at 1073 K, and that of the HVOF coating is over 350 MPa.

Similar content being viewed by others

References

K. Satoshi, S. Yuji, Y. Akihiro, I. Akira, and O. Hiromu:Kawasaki Steel Giho, 1987, vol. 19 (1), pp. 64–71 (in Japanese).

Chiyoshi Tonozaki:Welding Technique, 1988, vol. 36, pp. 75–84 (in Japanese).

Y. Fukuda, H. Yamasaki, M. Kumonn, and K. Kawamura:Proc. Attac ”88, High Temperature Society of Japan, Osaka, Japan, 1988, pp. 49–54.

P. Chraska, J. Dubsky, B. Kolman, J. Ilavsky, and J. Forman:J. Thermal Spray Technol., 1992, vol. 1 (4), pp. 301–06.

S. Rangaswarmy and H. Herman:Advances in Thermal Spraying, Pergamon Press, Elmsford, NY, 1986, pp. 101–10.

L. Russo and M. Dorfmann: inThermal Spraying—Current Status and Future Trends, A. Ohmori, ed., High Temperature Society of Japan, Osaka, 1995, pp. 681–86.

S. Basinska-Pampuch and T. Gibas:Ceram. Int., 1977, vol. 3 (4), pp. 152–58.

K.V. Rao, D.A. Somerville, and D.A. Lee:Advances in Thermal Spraying, Pergamon Press, Elmsford, NY, 1986, pp. 873–82.

E. Lugscheider, P. Remer, C. Herbst, K. Yushchenko, Y. Borisov, and A. Chernishov, P. Vitiaz, A. Verstak, B. Wielage, and S. Steinhäuser: inThermal Spraying—Current Status and Future Trends, A. Ohmori, ed., High Temperature Society of Japan, Osaka, 1995, pp. 235–40.

H. Era, F. Otsubo, T. Uchida, S. Fukuda, and K. Kishitake:Mater. Sci. Eng., 1998, vol. A251, pp. 166–72.

C.K. Lin, S.H. Leigh, and C.C. Berndt: inThermal Spraying—Current Status and Future Trends, A. Ohmori, ed., High Temperature Society of Japan, Osaka, 1995, pp. 903–08.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Otsubo, F., Era, H., Kishitake, K. et al. Properties of Cr3C2-NiCr cermet coating sprayed by high power plasma and high velocity oxy-fuel processes. J Therm Spray Tech 9, 499–504 (2000). https://doi.org/10.1007/BF02608553

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02608553