Abstract

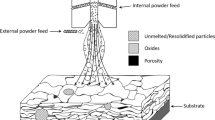

New controlled atmosphere on-site spraying systems were developed to deposit a high-quality coating with superior resistance to wet corrosion. Characteristics and corrosion resistance of coatings deposited by arc and flame spraying of wire in argon gas were compared with those of coatings deposited by conventional and low-pressure plasma techniques. It was found that the coating deposited by the arc spraying of wire in argon gas is free of oxides and possesses excellent corrosion resistance in chloride and acid solutions. The coating suffers slight pitting and crevice corrosion associated with the isolated pores and electric potential paths. Corrosion resistance was improved by using a modified spraying system.

Similar content being viewed by others

References

T. Kato, H. Saito, M. Nakajima, and G. Ueno, Application of Thermal Sprayed Coating for Anti-Corrosion in Chemical Equipments,Proc. Surf. Eng. Int. Conf., Japan Thermal Spraying Society, Tokyo, 1988, p 397–404

T. Sakaki, M. Kato, and G. Ueno, Application of Sprayed Cr-Ni Coating to Alkaline Plant,Thermal Spraying Technol., Vol 9 (No. 4), 1990, p 72–77 (in Japanese)

M. Takemoto, Laser Surface Modification of Plasma Sprayed Oxide Ceramic Coat for Anti-Corrosion Performance,High Power Laser, Niku Lari, Ed., Pergamon Press, Oxford, 1989, p 75–88

K. Hayashi, S. Kajiwara, K. Fujiwara, and M. Inaba, Damage and Consumption Process for Al-Zn Alloy Thermal Sprayed Coat of Open Rack Vaporizer,Kobe Res. Develop., Vol 41 (No. 4), 1991, p 111–114

Y. Enami and M. Takemoto, Laser Treatment of Sprayed Ni-Cr Coat for Anti-Corrosion Performance,Corns. Eng., Vol 39 (No. 8), 1990, p 416–424

K. Kamachi, N. Tani, T. Shibata, and G. Ueno, Reactive Diffusion Thermal Sprayed Aluminum and the Base Metal of Austenitic Stainless Steel and Its Effects on Cracking Behavior by Stress Corrosion Cracking,Corros.Eng., Vol 39 (No. 3), 1990, p 113–118 (in Japanese)

M. Murakawa, S. Watanabe, and Y. Sugimoto, On Some Application of Thermal Sprayed Coating with HIP Post Treatment,J. Jpn. Thermal Spraying Soc., Vol 25 (No. 3), 1988, p 18–26 (in Japanese)

Y. Longa and M. Takemoto, High Temperature Corrosion of Laser Glazed Alloys in Na2SO4-V2O5,Corrosion, Vol 48 (No. 7), 1992, p 599–607

Japanese Industrial Standard, “Testing Methods for Thermal Sprayed Ceramic Coatings,” JIS H 8666, 1980

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Takemoto, M., Ueno, G. Characteristics and corrosion performance of 80Ni-20Cr coating deposited by on-site thermal spraying. JTST 2, 59–68 (1993). https://doi.org/10.1007/BF02647424

Issue Date:

DOI: https://doi.org/10.1007/BF02647424