Abstract

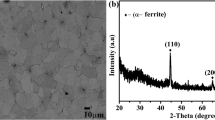

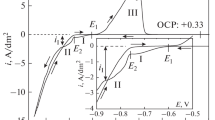

The iron content, phase constitution, and microstructure of electrodeposited iron-zinc alloy coatings deposited from chloride baths were investigated. It was found that the iron content of the coatings varied with the current density used during processing and that coatings containing 6 to 13 wt pct Fe consisted of nonequilibrium phases, η andG. η phase, hexagonal close-packed (hcp) zinc supersaturated with iron to about 8 wt pct Fe, contained nanometer-size crys-tals divided by 30-nm-wide growth steps. Within the growth steps, an amorphous phase was present. TheG phase, a body-centered cubic (bcc) phase similar to equilibrium γ phase, existed as equiaxed 30- to 80-nm-wide grains in 10 and 13 wt pct Fe coatings. It is suggested that the microstructure of higher iron content coatings resulted from a recovery/polygonization process.

Similar content being viewed by others

References

T.Actaniya, Y. Hara, M. Sagiyama, T. Homa, and T. Watanabe:Plating Surf. Finish., 1985, Aug., pp. 52-56.

K. Kondo, S. Hinotani, and Y. Ohmori:J. Appl. Electrochem., 1988, vol. 18, pp. 154–61.

M. Gu, M.R. Notis, and A.R. Marder: inProc. Int. Conf. on Zinc and Zinc Alloy Coated Steel Sheet, Galvatech '89, Keidanren Kaikan, Tokyo, 1989, pp. 462–77.

W.R. Johnson and L.E. Pfister: U.S. Patent 4,540,472,Official Gazette, 1985, p. 768.

R.J. Livak and G. Thomas:Acta Metall., 1974, vol. 22, pp. 589–99.

C.A. Drewien: Ph.D. Thesis, Lehigh University, Bethlehem, PA, 1992, p. 163.

Joint Committee on Powder Diffraction Standards (JCPDS): International Centre for Diffraction Data, Swarthmore, PA, 1990, Card No. 4-831.

N.A. Pangarov:Electrochim. Acta, 1964, vol. 9, pp. 721–26.

D.R. Clarke:Ultramicroscopy, 1982, vol. 8, pp. 95–107.

R.E. Reed-Hill:Physical Metallurgy Principles, 2nd ed., PWS- Kent Publishing Co., Boston, MA, 1973, p. 273.

B.D. Cullity:Elements of X-ray Diffraction, 2nd ed., Addison- Wesley Publishing Co., Reading, MA, 1978, pp. 284–92.

H. Hu: inRecovery and Recrystallization of Metals, L. Himmel, ed.. Interscience, New York, NY, 1963, pp. 311–61.

Author information

Authors and Affiliations

Additional information

C.A. Drewien, formerly with Lehigh University, is a Senior Member-Technical Staff in the Materials Process and Sciences Center at Sandia National Laboratories, Albuquerque, NM 87185. J.I.

Goldstein, formerly with Lehigh University, is Dean of Engineering at the University of Massachusetts-Amherst, Amherst, MA 01003.

Rights and permissions

About this article

Cite this article

Drewien, C.A., Goldstein, J.I. & Marder, A.R. Structure of as-deposited iron-zinc coatings from chloride bath. Metall Mater Trans A 25, 249–255 (1994). https://doi.org/10.1007/BF02647970

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647970