Abstract

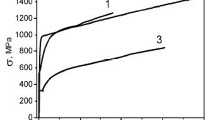

Parallel fracture mechanics and surface chemistry studies were carried out to develop further understanding of environment assisted subcritical crack growth in high strength steels. The kinetics of crack growth for an AISI 4340 steel (tempered at 477 K) in high purity hydrogen sulfide have been determined as a function of pressure at room temperature and as a function of temperature at hydrogen sulfide pressures of 0.133 and 2.66 kPa. The kinetics for the reactions of hydrogen sulfide with this steel and the extent of reactions were also determined. Two rate controlling processes have been identified. At the lower pressure, the rate of crack growth varies according to T1/2 and is controlled by the rate of transport of hydrogen sulfide to the crack tip. At the higher pressure, crack growth is controlled by the rate of diffusion of hydrogen into the steel ahead of the crack tip and exhibits an apparent activation energy of about 5 kJ/mol. Embrittlement results from hydrogen that is produced by the reactions of hydrogen sulfide with the steel. These reactions are extremely rapid and are limited in extent, leading to the formation of one to two layers of “sulfide” on the fracture surfaces. The crack growth results are discussed in terms of measured reaction kinetics and published data on diffusion, and in relation to models for transport- and diffusion-controlled crack growth.

Similar content being viewed by others

References

G. W. Simmons, P. S. Pao, and R. P. Wei:Met. Trans. A, 1978, vol. 9A, p. 1147.

R. P. Gangloff and R. P. Wei:Met. Trans. A, 1977, vol. 8A, p. 1043.

P. S. Pao and R. P. Wei:Scr. Met., 1977, vol. 11, p. 515.

H. G. Nelson, D. P. Williams, and A. S. Tetelman:Met. Trans., 1971, vol. 2, p. 953.

D. P. Williams and H. G. Nelson:Met. Trans., 1970, vol. 1, p. 63.

H. H. Johnson:Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Based Alloys, J. Hochmann, J. Slater, and R. W. Staehle, eds., p. 382, NACE-5, 1978.

R. P. Wei, S. R. Novak, and D. P. Williams:Mat: Res. Stand., 1972, vol. 12, p. 25.

M. Lu, P. S. Pao, N. H. Chan, K. Klier, and R. P. Wei:Hydrogen in Metals, suppl. to Trans. Jpn. Inst. Metals, 1980, vol. 21, p. 449.

D. P. Williams, P. S. Pao, and R. P. Wei:Environment Sensitive Fracture of Engineering Materials, Z. A. Foroulis, ed., p. 3, The Metall. Soc.-AIME, Warrendale, PA, 1979.

N. H. Chan, K. Klier, and R. P. Wei:Hydrogen in Metals, suppl to Trans. Jpn Inst. Metals, 1980, vol. 21, p. 305.

D. J. Dwyer: Ph.D. Dissertation, Lehigh University, Bethlehem, PA, 1976.

R. P. Wei and R. L. Brazill: “An a.c. Potential System for Crack Length Measurement”,The Measurement of Crack Length and Shape During Fracture and Fatigue, C. J. Beevers, ed., Engineering Materials Advisory Services Ltd (EMAS), Warley, England, 1980.

R. P. Wei and R. L. Brazill: “An Assessment of ac and dc Potential Systems for Monitoring Fatigue Crack Growth”,Proceedings of ASTM Symposium on Fatigue Crack Growth Measurement and Data Analysis, Pittsburgh, PA, Oct., 1979, ASTM STP 738, 1981.

G. W. Simmons and D. J. Dwyer:Surface Sci., 1975, vol. 48, p. 373.

D. J. Dwyer, G. W. Simmons, and R. P. Wei:Surface Sci., 1977, vol. 64, p. 617.

R. P. Wei and G. W. Simmons:Scr. Met., 1976, vol. 10, p. 153.

D. Brennan, D. O. Hayward, and B. M. Trapnell:Proc. Roy. Soc. Ser. A (London), 1960, vol. 256, p. 81.

T. W. Weir, G. W. Simmons, R. G. Hart, and R. P. Wei:Scr. Met., 1980, vol. 14, p. 357.

S. Dushman:Scientific Foundations of Vacuum Technique, 2nd ed., J. M. Lafferty, ed., p. 88, Wiley, 1962.

H. H. Johnson:Hydrogen in Metals, I. M. Bernstein, ed., p. 35, ASM, Metals Park, OH, 1973.

William W. Gerberich:Hydrogen in Metals, I. M. Bernstein, ed., p. 115, ASM, Metals Park, OH, 1973.

H. P. Van Leeuwen:Effect of Hydrogen on Behavior of Materials, A. W. Thompson and I. M. Bernstein, eds., p. 480, 1975.

R. Raj and V. K. Varadan:Mechanisim of Environment Sensitive Cracking of Materials, R. P. Swan, F. P. Ford, and A. R. C. Westwood, eds., p. 427, 1977.

M. Lu and R. P. Wei: “A Model for Diffusion Controlled Crack Growth in Gaseous Environment”, unpublished results. Lehigh University, Bethlehem, PA, 1980.

R. F. Miller, J. B. Hudson and G. S. Ansell:Met. Trans. A, 1975, vol. 6A, p. 117.

J. Völkl and G. Alefeld:Hydrogen in Metals I, G. Alefeld and J, Völkl, eds., p. 326, Springer-Verlag, 1978.

T. Heumann and E. Domke:Jül-Bericht Jül-Conf. 6, vol. II, p. 492, KFA-Jülich, 1972.

P. McIntyre:The Relationships Between Stress Corrosion Cracking and Subcritical Flaw Growth in Hydrogen and Hydrogen Sulphide Gases, R. W. Staehle, J. Hochmann, R. D. McCright and J. E. Slater, eds., p. 788, NACE-5, 1977.

Author information

Authors and Affiliations

Additional information

Formerly with Lehigh University, Bethlehem, PA

Rights and permissions

About this article

Cite this article

Lu, M., Pao, P.S., Weir, T.W. et al. Rate controlling processes for crack growth in hydrogen sulfide for an alsl 4340 steel. Metall Trans A 12, 805–811 (1981). https://doi.org/10.1007/BF02648345

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02648345