Abstract

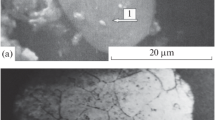

Mechanical alloying of two aluminum alloy powders to form composite A1-A12O3 powders has been studied. Changes in powder microstructure with processing are reported and interpreted. Mechanical alloying proceeds by the continual cold welding and fracturing of the constituent powder particles when subjected to the large compressive forces of a high speed mill. A suitable organic surfactant must be added so that a balance between cold welding and fracturing is obtained. The organic surfactant is embedded and finely distributed in the powder particles during mechanical alloying and is converted to discrete A14C3 particles after hot pressing. The establishment of steady state processing conditions, characterized by equiaxed powder particles, a constant particle size distribution and a saturation hardness, is found to depend on the size distribution of the initial powders. The oxide particles formed and distributed during mechanical alloying are equiaxed, small (30 nm) and homogeneously distributed with a volumetric center to center distance of about 60 nm.

Similar content being viewed by others

References

J. S. Benjamin:Met. Trans., 1970, vol. 1, p. 2943.

T. E. Volin: U. S. Patent No. 3,877,930 (Apr. 15, 1975).

ASTM Standard B 214-66.

E. A. Bloch:Metall. Rev., 1961, vol. 6, p. 193.

N. Hansen:Powder Met., 1967, vol. 10, p. 94.

J. S. Benjamin and T. E. Volin:Met. Trans., 1974, vol. 5, p. 1929.

H. Hausner:Handbook of Powder Met., p. 331, Chem. Pub. Co., Inc., 1973.

J. S. Benjamin and M. J. Bomford:Met. Trans. A, 1977, vol. 8A, p. 1301.

G. H. Gessinger:Met. Trans. A, 1976, vol. 7A, p. 1203.

D. L. Klarstrom and R. Grierson: Air Force Materials Laboratory Technical Report, TR-74-34, March (1974).

I. G. Wright and B. A. Wilcox:Met. Trans., 1974, vol. 5, p. 957.

L. H. Willey:Metals Handbook, 8th ed., 1973, vol. 8, p. 396.

J. R. Lloyd and S. Nakahara:J. Vac. Sci. Technot., 1977, vol. 14, p. 655.

N. Hansen:J. Nucl. Mater., 1972, vol. 43, p. 339.

N. Hansen:Acta Met., 1976, vol. 18, p. 1376.

G. Blankenburgs:J. Aust. Inst. Met., 1969, vol. 14, p. 236.

G. L. Copeland, M. M. Martin, D. G. Harman, and W. R. Martin:Powder Technol., 1969/1970, vol. 3, p. 136.

A Berndorf: French Patent Applic., 2,239,535 (Feb. 28, 1973); Austrian, 6779/73 (Aug. 2, 1973).

G. Jangg, F. Kutner, and G. Korb:Powder Met. Int., 1977, vol. 9, p. 24.

N. Hansen, B. Kindl, and E. Adolph:Les Mem. Sci. Rev. Met., 1963, vol. 60, p. 285.

J. H. Dudas and W. A. Dean:Int. J. Powder Met., 1969, vol. 5, p. 21.

E. J. Westerman and F. V. Lenel:Trans. TMS-AIME, 1960, vol. 218, p. 1010.

D. Nobili and R. De Maria:J. Nucl. Mater., 1965, vol. 17, p. 5.

N. Hansen and B. Bay:J. Mater. Sci., 1972, vol. 7, p. 1351.

Author information

Authors and Affiliations

Additional information

Formerly Graduate Research Assistant in the Department of Materials Science and Engineering at Stanford.

Rights and permissions

About this article

Cite this article

Gilman, P.S., Nix, W.D. The structure and properties of aluminum alloys produced by mechanical alloying: Powder processing and resultant powder structures. Metall Trans A 12, 813–824 (1981). https://doi.org/10.1007/BF02648346

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02648346