Abstract

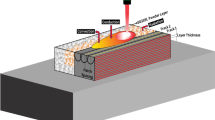

A major trend in the thermal spray industry has been to increase the gas jet velocity to obtain better coating attributes. One emerging technology now used in industry is the high-velocity oxygen fuel process (HVOF). High-velocity spray guns combine oxygen and a fuel gas to generate heat and extremely high particle velocities. In this study, Inconel 718 powder was deposited on steel substrates. The primary coating function was electrical resistivity for a heater application. Experiments were conducted using a Taguchi L8 statistical fractional/factorial design parametric study. The Taguchi experiment evaluated the effect of six HVOF processing variables on the measured responses. The parameters were oxygen flow, fuel flow, air envelope gas flow, powder feed rate, spray distance, and nozzle configuration. The coatings were characterized by hardness tests, surface profilometry, optical metallography, and image analysis. This article investigates coating hardness, porosity, surface roughness, deposition efficiency, and microstructure with respect to the influence of the processing parameters. Analytical studies were conducted to investigate gas, particle, and coating dynamics for two of the HVOF thermal spray experiments.

Similar content being viewed by others

References

E.J. Kubel, Thermal Spraying Technology: From Art to Science,Adv. Mater. Proc, Vol 132 (No. 6), Dec 1987, p 69–80

D.W. Parker and G.L. Kutner, HVOF—Spray Technology—Poised for Growth,Adv. Mater. Proc., Vol 139, Apr 1991, p 68–74

R.W. Kaufold, A.J. Rotolico, J.E. Nerz, and B.A. Kushner, Deposition of Coatings Using a New High Velocity Combustion Spray Gun,Thermal Spray Research and Applications, T.F. Bernecki, Ed., ASM International, 1991,p561-569

A.D. Hewitt, Technology of Oxyfuel Gas Processes,Weld. Met. Fabr., Nov 1972, p 382-389

T.J. Steeper, D.J. Varacalle, Jr., G.C. Wilson, and V.T. Berta, Use of Thermal Spray Processes to Fabricate Heater Tubes for Use in Thermal-Hydraulic Experiments,Thermal Spray Coatings: Properties, Processes,and Applications, T.F. Bernecki, Ed., ASM International, 1991, p 425-432

T.J. Steeper, D.J. Varacalle, Jr., G.C. Wilson, A.J. Rotolico, J.E. Nerz, and W.L. Riggs, A Taguchi Experimental Design Study of Plasma Sprayed Alumina-Titania Coatings,Thermal Spray Coatings: Properties,Processes, and Applications, T.F. Bernecki, Ed., ASM International, 199 l,p 13-20

G. Taguchi and S. Konishi,Taguchi Methods: Orthogonal Arrays and Linear Graphs, ASI Press, 1987

R.F. Culp,“Speedy Analysis and Design of Industrial Experiments,” (SADIE), GE Medical Systems, Milwaukee, 1990

Y.C. Lee,“Modeling Work in Thermal Plasma Processing,” Ph.D. thesis, University of Minnesota, Minneapolis, 1984; available from University Microfilms International, DER84-24718

D.J. Varacalle, Jr., An Analytical Methodology to Predict the Coating Characteristics of Plasma-Sprayed Ceramic Powders,Thermal Spray Research and Applications, T.F. Bernecki, Ed., ASM International, 1991,p271-283

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Varacalle, D.J., Ortiz, M.G., Miller, C.S. et al. HVOF Combustion spraying of inconel powder. JTST 2, 151–158 (1993). https://doi.org/10.1007/BF02652023

Issue Date:

DOI: https://doi.org/10.1007/BF02652023