Abstract

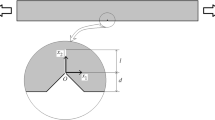

To fully characterize the mechanical behavior of ceramics, it is useful to study their response to both tensile and bending tests. In this investigation, a quantitative comparison is made between tensile and bending results from (circularly) cylindrical glass rods of borosilicate glass and of fused silica. These experimental results show that in each material, the Weibull exponentm is approximately the same for both types of test. The fractured samples clearly showed that all failures initiated at surface-located flaws. The stress level at which the probability of fracture in tension equals 50 Pct was determined; the maximum tensile stress for 50 Pct probability of fracture in bending was also determined. The ratio of these two stresses was predicted previously from simple, theoretical considerations based upon the applicability of the Weibull function and on the distribution of defects in the specimens. This theoretical result is inconsistent with the experimental observations in view of the fractography. Therefore, it is concluded that failure in the materials tested is not satisfactorily described by Weibull statistics.

Similar content being viewed by others

References

S.W. Freiman: inGlass Science and Technology, D. Uhlman and N.J. Kreidl, eds., Academic Press, New York, NY, 1980, vol. 5, pp. 21–78.

C.W. Marshall and A. Rudnick: inFracture Mechanics of Ceramics, R.C. Brandt, D.P.H. Hasselman, and F.F. Lange, eds., Plenun Press, New York, NY, 1974, vol. 1, pp. 69–92.

R.E. Medrano and J.M.L. Costa: inProc. VII Interamerican Conf. on Materials Technology, Southwest Research Institute, San Antonio, TX, 1981, pp. 711–15.

R.J. Charles:J. Appl. Phys., 1958, vol. 29, pp. 1657–62.

M.A.R. Lucas, R.E. Medrano, and P.P. Gillis:Metall. Trans. A, 1991, vol. 22A, pp. 887–71.

J.E. Ritter and C.C. Sherburne:J. Am. Ceram. Soc, 1971, vol. 54, pp. 601–05.

H. Furutomi:Optical Fiber Cable, The Telecommunication Association, Tokyo, Japan, 1986.

P.W. France and W.J. Duncan: inPhysics of Fiber Optics, Advances in Ceramics, B. Bendow and S.S. Mitra, eds., American Ceramic Society, Columbus, OH, 1981, vol. 2, pp. 149–57.

W. Weibull:J. Appl. Mech., 1951, vol. 18, pp. 293–97.

K.C. Kapur and L.R. Lamberson:Reliability in Engineering Design, John Wiley & Sons, New York, NY, 1977, pp. 291–338.

S. Timoshenko:Strength of Materials, D. Van Nostrand Co., New York, NY, 1956.

J.A. Kies: NRL Report No. 5093, Naval Research Laboratory, Washington, DC, 1958.

R.E. Medrano and P.P. Gillis:J. Am. Ceram. Soc, 1987, vol. 70, pp. C230-C232.

J.J. Mecholsky, S.W. Freiman, and R.W. Rice: Special Technical Publication No. 645, pp. 363–79, ASTM, Philadelphia, PA, 1978.

J.W. Johnson and D.G. Holloway:Phil. Mag., 1966, vol. 14, pp. 731–43.

J. Mecholsky, S.W. Frieman, and S.M. Morey:Fiber Optics, Advances in Research and Development, B. Bendow and S.S. Mitra, eds., Plenum Press, New York, NY, 1979, pp. 187–208.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Alarcón, O.E., medrano, R.E. & Gillis, P.P. Fracture of glass in tensile and bending tests. Metall Mater Trans A 25, 961–968 (1994). https://doi.org/10.1007/BF02652271

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652271