Abstract

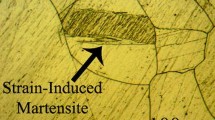

The grain structures in two dimensional GTA welds of a number of commercial aluminum alloys have been studied in order to clarify the mechanisms of grain refinement in welds. At low welding speeds and heat inputs the structures were either axial (continuous grains along the weld centerline) or stray (intermittent new grains). At higher speeds and heat inputs the structures were generally either columnar to the weld centerline, or contained some equiaxed grains at the center. Regression analyses indicated that both stray grains and equiaxed grains were favored by increased titanium content. In several alloys, titanium-rich compounds, and in one alloy, zirconium-rich compounds were found at the centers of dendrites. It is concluded that both stray and equiaxed grains originate by heterogeneous nucleation, with possible secondary effects due to constitutional undercooling.

Similar content being viewed by others

References

W.F. Savage:Weldments: Physical Metallurgy and Failure Phenomena, R. J. Christoffelet al, ed., General Electric Co., Schenectady, NY, 1979, pp. 1–18.

J. Hernaez and A. Madronero:Weld. J., 1972, vol. 51, pp. 281S-294S.

G. J. Davies and J. G. Garland:Int. Metall. Rev., 1975, vol. 20, pp. 83–106.

T. Ganaha and H. W. Kerr:Met. Technol., 1978, vol. 5, pp. 62–69.

M. Kato, F. Matsuda and T. Senda:Weld. Res. Abroad, 1973, vol. 19(2), pp. 26–33.

Y. Arata, F. Matsuda, and A. Matsui:Trans. Jpn. Weld. Res. Inst., 1974, vol. 3, pp. 89–97.

H. W. Ghent, C. E. Hermance, H. W. Kerr, and A. B. Strong:Arc Physics and Weld Pool Behaviour, Conference Proceedings, The Welding Institute, Cambridge, UK, 1979.

W. H. S. Lawson and H. W. Kerr:Weld. Res. Int., 1976, vol. 6(5) pp. 63–77 and 6(6), pp. 1–17.

J. Cissé, H. W. Kerr and G. F. Boiling:Met. Trans., 1974, vol. 5, pp. 633–641.

J. Cissé, G. F. Boiling and H. W. Kerr:J. Cryst. Growth, 1972, vol. 13/14, pp. 777–81.

A. J. Cornish:Met. Sci., 1975, vol. 9, pp. 477–484.

G. W. Delamore and R. W. Smith:Met. Trans., 1971, vol. 2, pp. 1733–38.

B. Chalmers:Principles of Solidification, J. Wiley and Sons, New York, 1964, p. 106.

G. F. Boiling:Solidification, ASM, Metals Park, OH, 1971, p. 365.

J. F. Lancaster:The Metallurgy of Welding, Brazing and Soldering, Geo. Allen and Unwin, London, 1970, p. 48.

Author information

Authors and Affiliations

Additional information

Formerly Graduate Student, University of Waterloo

Rights and permissions

About this article

Cite this article

Ganaha, T., Pearce, B.P. & Kerr, H.W. Grain structures in aluminum alloy GTA welds. Metall Trans A 11, 1351–1359 (1980). https://doi.org/10.1007/BF02653489

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02653489