Abstract

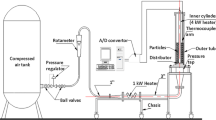

The characterization of heat flow processes in direct-fired rotary kilns requires detailed measurements of gas, solids and wall temperatures. This paper describes the construction, instrumentation and operation of a 5.5 m long x 0.406 m inside diam kiln designed for such measurements. The heating of inert sand was chosen for experimental study. Methods of calculating heat flows among solids, wall and gas from the measured axial and radial temperatures are presented and the heat balance calculations and other necessary checks on the validity of the data are given. The effects of the kiln operating variables on heat flow rates, and the implications of the results for modelling and scale-up to large kilns are discussed in Part II.

Similar content being viewed by others

Abbreviations

- A :

-

Area, m2

- Cp :

-

Heat capacity, J/kg K

- D :

-

Inside diam of kiln, m

- F :

-

Degree of fill of kiln

- Gg :

-

Mass flow rate of gas, g/s

- Gs :

-

Mass flow rate of solids, g/s

- H :

-

Bed depth, m

- h :

-

Heat transfer coefficient, w/m2 K

- k :

-

Thermal conductivity, W/m K

- L :

-

Length coordinate, m

- q :

-

Heat flow rate, W

- q:

-

Average heat flow rate, W

- r :

-

Radius, m

- rw :

-

Inside radius of kiln, m

- T :

-

Temperature, K

- T :

-

Circumferential average temperature, K

- Tg :

-

Average gas temperature defined by Eq. [1] K,

- Tg :

-

Average gas temperature defined by Eq. [2] K,

- x :

-

Axial distance coordinate, m

- ε:

-

Emissivity

- σ :

-

Stefan Boltzmann constant, w/m2K4

- Gr :

-

Grashof number

- Pr :

-

Prandtl number

- Reω :

-

Reynolds number (rotational)

- te]a :

-

air

- E, F, F′ :

-

positions in Fig. 3

- g :

-

gas

- l :

-

loss

- o :

-

outside

- r :

-

reference

- s :

-

solids

- sh :

-

shell

- w :

-

wall

References

F. J. Farago and R. R. Sood: TMS Paper Selection, No. 76–20, TMS-AIME, 1976.

R. R. Sood, R. Clark, and D. M. Stokes: TMS Paper Selection, No. 72–28, TMS-AIME, 1972.

K. R. K. Bhilotra: TMS Paper Selection, No. A73-40, TMS-AIME, 1973.

P. O. Pape, R. D. Frans and G. H. Geiger:Ironmaking and Steelmaking, 1976, vol. 3, pp. 138–45.

J. G. Sibakin:Yearbook of AISI, 1962, pp. 187–228.

M. J. Fraser and C. R. Grigg:Eng. J., 1965, vol. 48, no. 6, pp. 29–34.

H. E. Cross and F. O. Read:AIME Symp. Mining and Metallurgy of Lead and Zinc, C. H. Cotterill and J. M. Cigan, eds., 1970, vol. II, pp. 918–59.

M. Kashiwada and T. Kumagai:ibid, pp. 409–22.

J. R. Boldt, Jr.:The Winning of Nickel, 1967, Longmans Canada Ltd., Toronto.

K. E. Peray and J. J. Waddell:The Rotary Cernent Kiln, Chemical Publishing Co., Inc., New Kork, 1972.

R. S. Boynton:Chemistry and Technology of Lime and Limestone, Interscience Publishers, New York, 1966.

Chemical Engineers'Handbook, J. H. Perry, ed., 4th ed., McGraw-Hill, New York, 1963, pp. 20–23, 20–25.

M. Imber and V. Paschkis:Radex-Rundschau, 1960, vol. 4, pp. 183–97.

M. Imber and V. Paschkis:Int. J. Heat Mass Transfer, 1962, vol. 5, pp. 623–38.

K. W. Pearce:J. Inst. Fuel, 1973, vol. 46, pp. 363–71.

J. Kern:Int. J. Heat Mass Transfer, 1974, vol. 17, pp. 981–90.

W. Gilbert:Cement and Cement Manufacture, 1932, vol. 5, no. 12, pp. 417–25.

H. Gygi:Cement and Cement Manufacture, 1938, vol. 11, p. 81.

A. Folliot: Publication Technique No. 70, Centre d'Etudes et de Recherches de l'Industrie des Liants Hydrauliques, Paris, 1955.

P. Weber:Heat Transfer in Rotary Kilns, 1963, Bauverlag GmbH, Wiesbaden, Berlin.

T. G. Bowers and H. L. Read:Chem. Eng. Prog. Symp. Series, 1968, vol. 61, no. 57, pp. 340–46.

B. Tettmar: Fourth Meeting of the Heat Transfer Panel, Doc. nr. G 04/ca/2, I.F.R.F., 1971,IJmuiden.

K. W. Pearce:J. Chem. E. Symp. Series No. 43, 1976, pp. 26–1-26-14.

G. W. J. Wes, A. A. H. Drinkenburg, and S. Stemerding:Powder Tech., 1976, vol. 13 pp. 185–92.

S. J. Friedman and W. R. Marshall:Chem. Eng. Prog., 1949, vol. 45, no. 9, pp. 573–88.

C-C. Chen. W-M. Lu, and L-T. Teng:J. Chinese Inst. Chem. Engrs., 1974, vol. 5, pp. 1–6.

J. Lehmberg, M. Hehl, and K. Schügerl: International Conference SPIRE, 1975, Arad, Israel.

L. H. J. Wachters and H. Kramers: Third Symp. Chem. React. Eng. Amsterdam, 1964, pp. 77–86.

A. W. D. Hills and A. Paulin:J Sci. Instr. (J. Phys. E) 1969, Ser. 2, vol. 2, pp. 713–17.

Author information

Authors and Affiliations

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/BF03257229.

Rights and permissions

About this article

Cite this article

Brimacombe, J.K., Watkinson, A.P. Heat transfer in a direct-fired rotary kiln: I. Pilot plant and experimentation. Metall Trans B 9, 201–208 (1978). https://doi.org/10.1007/BF02653685

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02653685