Abstract

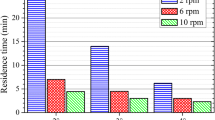

Looking forward to the need of developing coal-based sponge iron technology in India, a country having no significant resources of either coking coal or natural gas, the Research and Development Division of the Tata Iron and Steel Company Limited (TISCO) set up a rotary kiln based direct reduction pilot plant in 1975. In this pilot plant, a totally indigenous technology for production of sponge iron has been developed in which non-coking coal is essentially used as the reductant. For easy scaling up of the TISCO Direct Reduction (TDR) process to units of 300 to 400 tpd capacity, it was thought necessary to explore some of the fundamental aspects of material flow in a rotary kiln. This was carried out by studying the flow of materials in room temperature models. The work was divided into two parts: first, a study of the influence of several operating parameters,viz., rotational speed, inclination of the kiln, effect of circular dams at the feed and the exit ends of the kiln,etc., and second, an investigation of the extent of segregation of a mixture of solids in a rotating kiln. The highlights of the experimental results dealing mainly with the effect of various kiln operating variables on the filling degree profile of the charge in the kiln are presented.

Similar content being viewed by others

References

Amit Chatterjee and P. K. Chakravarty:Iron and Steel International, 1976, vol. 49, no. 3, pp. 201–14.

Amit Chatterjee and P. K. Chakravarty:Iron and Steel International, 1977, vol. 50, no. 4, pp. 245–52.

Amit Chatterjee and P. K. Chakravarty: Indian Patent No. 142368.

S.J. Friedman and W. R. Marshall:Chem. Engg. Progr., 1949, vol. 45, no. 8, pp. 482–93.

W.C. Saeman:Chem.Engg.Progr., 1951, vol. 47,no. 10, pp. 508–14.

D.S. De and S.G. Mukherjee:Indian Chemical Engineer., 1975, vol. 27, no. 2, pp. 3–7.

G. Reuter: Doctoral Thesis, 1975, University of Aachen.

Allis-Chalmers Bulletin on Rotary Kilns, Milwaukee, WI, no. 22B, 1423.

R. Hogg, K. Shoji, and L. G. Austin:Powder Technology, 1974, vol. 9, pp. 99–106.

R.W. Pickering, F. Feakes, and M. L. Fitzgerald:J. Appl. Chem., 1951, vol. 1, pp. 13–19.

A. Z. M. Abouzeid and D. W. Fuerstenau:Powder Technology, 1980, vol. 25, pp. 21–29.

A. Z. M. Abouzeid and D. W. Fuerstenau:Powder Technology, 1980, vol. 25, pp. 65–70.

V. K. Karra and D. W. Fuerstenau:Powder Technology, 1977, vol. 16, pp. 23–28.

Author information

Authors and Affiliations

Additional information

Formerly Joint Director, Research and Development, TISCO

Formerly with TISCO, Jamshedpur

Rights and permissions

About this article

Cite this article

Chatterjee, A., Sathe, A.V., Srivastava, M.P. et al. Flow of materials in rotary kilns used for sponge iron manufacture: Part I. Effect of some operational variables. Metall Trans B 14, 375–381 (1983). https://doi.org/10.1007/BF02654356

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02654356