Abstract

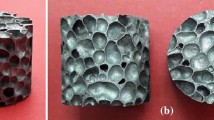

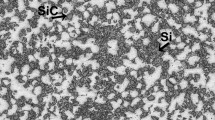

The compressive flow behavior of Al, Al−7 pct Mg and 7075 Al alloy foams has been determined in structures whose void fraction varies from 0.80 to 0.95 of the total volume. In all cases, a greater than linear increase in flow strength with increase in density was exhibited, indicating that bending stresses within the foam structure are an important feature of the collapse mode. The flow strength did not follow proportionately changes in bulk flow strength in comparisons of either alloy or of heat-treatment conditions. Ancillary tensile and metallographic observations show that this lack of correlation arises because the different foams collapse by different modes with localized fracture becoming dominant in the higher strength 7075 alloy. The energy absorbing efficiency was found to be independent of foam density for all the materials. However, the efficiency was found to be a strong function of the alloy and heat treatment increasing from about 30 pct in Al, to 43 pct in Al−7 pct Mg and to 50 pct in the solution heat treated and aged 7075 alloy. The increase in efficiency occurs because of an increase in the propensity to fracture in the higher strength alloys which introduces the potential for a propagating constant-stress collapse process.

Similar content being viewed by others

References

H. A. Kuhn and C. L. Downey:J. Eng. Materials and Technology, Trans. ASME, 1973, vol. 95, pp. 41–46.

W. Thiele:Metals Mater., 1972, vol. 6, no. 8, pp. 349–52.

E. A. Meinecke and R. C. Clark:Mechanical Properties of Polymeric Foams, Technomic, Westport, Conn., 1973.

K. C. Rusch:J. Appl. Polym. Sci, 1970, vol. 14, pp. 1433–47.

K. C. Rusch:J. Appl. Polym. Sci., 1969, vol. 13, pp. 2297–2311.

A. N. Gent and A. G. Thomas:J. Appl. Polym. Sci., 1959, vol. 1, pp. 107–13.

J. M. Lederman:J. Appl. Polym. Sci., 1971, vol. 15, pp. 693–703.

V. A. Matonis:SPE J., 1964, vol. 20, pp. 1024–30.

R. Chan and M. Nakamura:J. Cell Plast., 1969, vol. 5, no. 2, pp. 112–18.

M. R. Patel and I. Finnie:J. Mater., 1970, vol. 5, no. 4, pp. 909–32.

M. C. Shaw and T. Sata:Int. J. Mech Sct., 1968, vol. 8, pp. 469–78.

G. F. Bolling and R. H. Richman:Phil. Mag., 1969, vol. 19, pp. 247–64.

W. L. Fink and D. W. Smith:Trans. AIME, 1937, vol. 126, pp. 162–67.

R. E. Stotchdopole and L. C. Rubens:J. Cell. Plast., 1965, vol. 1, pp. 91–96.

C. E. Massonnet and M. A. Save:Plastic Analysis and Design, vol. 1, Blaisdell, New York, 1965.

S. P. Timoshenko and J. M. Gere:Theory of Elastic Stability, McGraw Hill, New York, 1961.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thornton, P.H., Magee, C.L. The Deformation of aluminum foams. Metall Trans A 6, 1253–1263 (1975). https://doi.org/10.1007/BF02658535

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02658535