Abstract

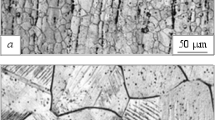

This paper reports a study of the effects of phosphorus, tin, and molybdenum on the caustic stress corrosion cracking susceptibility of NiCrMoV rotor steels. Constant load tests were performed on these steels in 9M NaOH at 98 ± 1 °C at a controlled potential of either -800 mVHg/Hgo or -400 mVHg/Hgo. Times to failure were measured. The results show that at a potential of -400 mVHg/Hgo the segregation of phosphorus to grain boundaries lowers the resistance of these steels to caustic stress corrosion cracking. When molybdenum is removed from a steel that has phosphorus segregated to the grain boundaries, the steel’s resistance to stress corrosion cracking is improved. High purity alloys, both with and without molybdenum, show very good resistance to caustic cracking at this potential. At-800 mVHg/Hgo segregated phophorus has no effect; only molybdenum additions lower the resistance of the steel to caustic stress corrosion cracking. Segregated tin has little effect at either potential. Metallographic examination shows that one explanation for these results is that molybdenum and phosphorus, probably as anions precipitated from solution, aid in passivating the sides of the crack and thus help keep the crack tip sharp. This sharpness will increase the speed with which the crack will propagate through the sample. Furthermore, removal of molybdenum greatly increases the number of cracks which nucleate. This higher crack density would increase the relative area of the anode to the cathode and thus act to decrease the crack growth rate.

Similar content being viewed by others

References

J.M. Hodge and I.L. Mogford:Proc. Inst. Mech. Eng., 1979, vol. 193, p. 93.

J.L. Gray:Proc. Inst. Mech. Eng., 1972, vol. 186, p. 379.

D. Kalderon:Proc. Inst. Mech. Eng., 1972, vol. 186, p. 341.

A. R. Ellery:J. Australasian Inst. Metals, 1976, vol. 21, p. 103.

J. G. Parker and M. A. Sadler:Corrosion Sci., 1975, vol. 15, p. 57.

FredF. Lyle, Jr. and Herman C. Burghard, Jr.:Materials Perf., 1982, vol. 21, no. 11, p. 35.

Thomas G. McCord, Bruce W. Bussert, Robert M. Curran, and George C. Gould:Materials Perf., 1976, vol. 15, no. 2, p. 25.

B.W. Roberts and P. Greenfield:Corrosion, 1979, vol. 35, p. 402.

J.G. Parker:British Corrosion J., 1978, vol. 13, p. 75.

J.E. Reinoehl and W. E. Berry:Corrosion, 1972, vol. 28, p. 151.

D. Singbeil and D. Tromans:Metall. Trans. A, 1982, vol. 13A, p. 1091.

P. Doig and P.E. Flewitt:Corrosion Sci., 1977, vol. 17, p. 369.

R.S. Shalvoy, S.K. Duglin, and R. J. UndingenCorrosion, 1981, vol. 37, p. 49.

R.N. Parkins, P.W. Slattery, and B.S. Poulson:Corrosion, 1981, vol. 37, p. 651.

M. Henthorne and R. N. Parkins:British Corrosion J., 1967, vol. 2, p. 186.

J. D. Atkinson, A. M. Adams, M. A. M. Khan, and P. J. Worthington: Central Electricity Research Laboratory, Leatherhead, England, Report No. RD/L/N169/79, January 1980.

R. P. Harrison, D. deG. Jones, and J. F. Newman:Int. Conf. on Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Base Alloys, R.W. Staehle, J. Hoehmann, and R.D. McCright, eds., Ferminy, France; NACE, Houston, TX, 1977, p. 659.

J. Woodward: Ph.D. Thesis, University of Cambridge, Cambridge, England, 1981.

D. L. Newhouse and H. G. Holtz: ASTM STP 407,Temper Embrittlement in Steels, D.L. Newhouse, ed., 1968, p. 106.

G. C. Gould: ASTM STP 407,Temper Embrittlement in Steels, D. L. Newhouse, ed., 1968, p. 59.

G.C. Gould: ASTM STP 407,Temper Embrittlement in Steels, D.L. Newhouse, ed., 1968, p. 90.

D. L. Newhouse: ASTM STP 499,Temper Embrittlement of Alloy Steels, D.L. Newhouse, ed., 1972, p. 3.

C.J. Boyle, R.M. Curran, D.R. DeForest, and D.L. Newhouse:Proc. ASTM, 1962, vol. 62, p. 1156.

R. Narayan and M. C. Murphy:J. Iron and Steel Institute, 1973, vol. 211, p. 493.

L.F. Porter, G.C. Carter, and S.J. Manganello: ASTM STP 407,Temper Embrittlement of Steels, D.L. Newhouse, ed., 1968, p. 20.

J. F. Smith, J. H. Reynolds, and H. N. Southworth:Acta Met., 1980, vol. 28, p. 1555.

R. B.Diegle and D. A. Vermilyea:Corrosion, 1976, vol. 32, p. 303.

C.J. Mahon, Jr. and L. Marchut:J. Vacuum Sci. Tech., 1978, vol. 15, p. 430.

N. Bandyopadhyay and C.L. Briant:Corrosion, 1982, vol. 38, p. 125.

C. Lea and E. D. Hondros:Proc. Roy. Soc. London A, 1981, vol. 377, p. 477.

J. Kupper, H. Erhart, and H.J. Grabke:Corrosion Sci., 1981, vol. 21, p. 227.

K. L. Moloznik, C.L. Briant, and C.J. McMahon, Jr.:Corrosion, 1979, vol. 35, p. 331.

M.P. Seah, P.J. Spencer, and E. D. Hondros:Metal Sci., 1979, vol. 13, p. 307.

B. C. Edwards, B. L. Eyre, and G. Gage:Acta Met., 1980, vol. 28, p. 335.

A. E. Powers:Trans. ASM, 1956, vol. 48, p. 149.

J. F. Newman: Central Electricity Research Laboratory, Leatherhead, England, Report RD/L/N186/73, 1973.

T. Ogura, A. Makino, and T. Masumoto:ScriptaMet., 1980, vol. 14, p. 887.

A. H. Ucisik, C. J. McMahon, Jr., and H. C. Feng:Metall. Trans. A, 1978, vol. 8A, p. 321.

T. Ogura, C. J. McMahon, Jr., H. C. Feng.and V. Vitek:Acta Met., 1978, vol. 26, p. 1317.

R.A. Mulford, C.J. McMahon, Jr., D.P. Pope, and H.C. Feng:Metall. Trans. A, 1976, vol. 7A, p. 1183.

N. Bandyopadhyay and C.L. Briant:Scripta Met., 1982, vol. 16, p. 939.

D. A. Vermilyea:J. Electrochem. Soc, 1972, vol. 119, p. 405.

J. C. Scully:Corrosion Sci., 1975, vol. 15, p. 207.

J.F. Knott:Metals Tech., 1982, vol. 9, p. 86.

F. P. Ford, G.T. Burstein, and T. P. Hoar:J. Electrochem. Soc., 1980, vol. 127, p. 1325.

D. deG. Jones, J. F. Newman, and R. P. Harrison:Proc. Fifth International Congress on Metallic Corrosion, Norio Sato, ed., National Association of Corrosion Engineers, Houston, TX, 1974, p. 434.

N. Bandyopadhyay, C.L. Briant, P. Emigh, and F. P. Ford: ASTM STP 792, Micon 82: Optimization of Processing Properties and Service Performance through Microstructural Control, Halle Abrams, Elizabeth Clark, John Hood, and Brij Seth, eds., 1982, p. 104.

R. E. Peterson:Stress Concentration Factors, John Wiley and Sons, New York, NY, 1974, p. 20.

J. F. Knott:Metal Science, 1980, vol. 14, p. 327.

J.Q. Clayton and J.F. Knott:Metal Science, 1976, vol. 10, p. 63.

C.J. Cron.J.H. Payer, and R.W. Staehle:Corrosion, 1971, vol. 27, p. 1.

F. P. Ford: General Electric Company, Schenectady, NY, Report 81CRD280, 1981.

C.L. Briant, R.A. Mulford, and E. L. Hall:Corrosion, 1982, vol. 38, p. 468.

A.E. Yaniv, J.B. Lumsden, and R.W. Staehle:J. Electrochem. Soc, 1977, vol. 123, p. 490.

N. Bandyopadhyay and C. L. Briant: unpublished research, 1982.

M. Naka, K. Hashimoto, and T. Masumoto:Corrosion, 1976, vol. 32, p. 146.

M. J. Pryor and M. Cohen:J. Electrochemical Soc, 1951, vol. 98, p. 263.

G.H. Awad and T.P. Hoar:Corrosion Sci., 1975, vol. 15, p. 581.

A. M. J. Adams, J. D. Atkinson, F. P. Ford, and P. J. Worthjngton: Central Electricity Research Laboratories, Report RD/L/N36/75, May 1975.

M.P. Seah:Surface Science, 1975, vol. 53, p. 168.

Author information

Authors and Affiliations

Additional information

Formerly with the Department of Materials Science and Engineering, University of Pennsylvania, Philadelphia, PA.

Rights and permissions

About this article

Cite this article

Bandyopadhyay, N., Briant, C.L. Caustic stress corrosion cracking of NiCrMoV rotor steels—The effects of impurity segregation and variation in alloy composition. Metall Trans A 14, 2005–2019 (1983). https://doi.org/10.1007/BF02662368

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02662368