Abstract

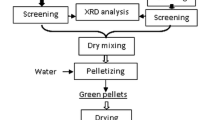

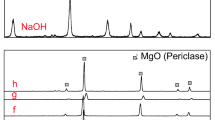

Pellets in the basicity range of 0.2 to 1.6 were produced from specular hematite concentrates using bentonite or peat moss as a binder. Specific pellet basicities were achieved through the addition of (1) limestone and (2) a combination of dolomite and limestone. Mineralogical study and microanalysis of the bonding and crystalline phases were done using scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). In limestone-fluxed pellets with bentonite as a binder, although formation of calcium ferrite was noted at the basicity of 0.8, its formation in appreciable quantities was delayed until the basicity of 1.6. For the pellets produced with a combination of dolomite and limestone, even at the basicity of 1.6, only minor amounts of this phase were present. In these pellets, some magnesioferrites were formed which did not conform to the stoichiometric composition (MgOFe2O2), but they were quite deficient in MgO. The silicate glass phases, which essentially provided the bonding in the pellets, showed a two-zone structure: (1) magnesian-ferruginous and (2) glass containing high quantities of Si and Ca. However, in pellets with only limestone addition, the zoned structure was less prevalent, probably due to low Mg content. The results indicate that using peat moss in conjunction with limestone, pellet sticking can be minimized at higher basicities. The factors influencing the pellet bonding and the change in the physical and chemical properties of these pellets are discussed.

Similar content being viewed by others

References

Z. I. Nekrasov, G. M. Drozdov, Y. S. Shmelev, M. G. Boldenko, and Y. G. Danko:Steel USSR, 1978, vol. 8 (8), pp. 429–35.

K. Meyer:Pelletization of Iron Ores, Springer-Verlag, Berlin, 1980, pp. 41–46, 121–26, and 151–53.

J. D. G. Hamilton:Trans. Inst. Min. Metall., Sect. C, 1976, vol. 85 (3), pp. C30–39.

M. C. Chang and D. B. Malcom: Proc. ISCTIC,Trans. Iron Steel Inst. Jpn., Suppl., 1971, vol. 11, pp. 66–70.

C. G. Thomas, J. D. G. Hamilton, and K. McG. Bowling:The Aus. I.M.M., Newcastle and District Branch, Pellets and Granules Symp., Australas. IMM, Melbourne, Australia, Oct. 1974, pp. 93–106.

M. Sasaki, T. Nakazawa, and S. I. Kondo:Trans. Iron Steel Inst. Jpn., 1968, vol. 8, pp. 146–55.

D. M. Urich and T.-M. Han:Agglomeration, W.A. Kneeper, ed., Interscience Publisher, New York, NY, 1962, pp. 669–719.

S. C. Panigrahy, M. Rigaud, I. Malinsky, and R. Tremblay:4th Int. Symp. on Agglomeration, Toronto, ON, Canada, ISS-AIME, Warrendale, PA, 1985, pp. 75-82.

R. Tremblay:Annual CIM Conf. of Metallurgists, Quebec, PQ, CanActa, CIM, Montreal, PQ, CanActa, Aug. 1984.

Iron Ore Pellets—Determination of Crushing Strength, ISO/4700, International Organization for Standardization, Geneva, Switzerland, 1983.

Iron Ore Determination of Reducibility, ISO/4695, International Organization for Standardization, Geneva, Switzerland, 1984.

M. Jallouli, M. Rigaud, and F. Ajersch:3rd Int. Symp. on Agglomeration, NMA Nürnberger Messe-Und Ausstellungs gesellschaft Messezentrum, Nuremberg, Federal Republic of Germany, 1981, pp. B81–103.

S. C. Panigrahy, M. Jallouli, and M. Rigaud:Ironmaking Proc., 1984, vol. 43, pp. 233–40.

A. E. Paladino:J. Am. Ceram. Soc., 1960, vol. 43 (4), pp. 183–91.

M. Koizumi and Rustum Roy:60th Annual Meeting, The American Ceramic Society, Pittsburgh, PA, Basic Science Div. No. 34-B-58, Apr. 1958.

M. Rigaud, B. C. Jena, S. C. Panigrahy, and G. Paquet:Iron Steel Soc. Trans., 1988, vol. 9, pp. 131–38.

K. Lingtan, Lu Yang, and W.-K. Lu:Scand. J. Metall., 1983, vol. 12, pp. 166–76.

D. H. St. John, S. P. Matthew, and P. C. Hayes:Metall. Trans. B, 1984, vol. 15B, pp. 709–17.

F. Nakiboglu, D. H. St. John, and P. C. Hayes:Metall. Trans. B, 1986, vol. 17B, pp. 375–81.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Panigrahy, S.C., Jena, B.C. & Rigaud, M. Characterization of bonding and crystalline phases in fluxed pellets using peat moss and bentonite as binders. Metall Trans B 21, 463–474 (1990). https://doi.org/10.1007/BF02667858

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02667858