Abstract

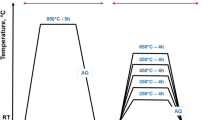

The influence of a range of austenitizing and subcritical (tempering) heat treatments on the high-stress abrasion resistance and fracture toughness of four commercially significant grades of alloy white cast iron was investigated. Complementing an earlier study[1] on the influence of a more limited range of heat treatments on the gouging abrasion performance of the same alloys, the results showed that the effect of austenitizing temperature on high-stress abrasion pin test weight loss differed for each alloy. With increasing austenitizing temperature, these results ranged from a substantial improvement in wear performance and retention of hardness through to vir-tually no change in wear performance and substantial falls in hardness. Fracture toughness, however, increased markedly in all alloys with increasing austenitizing temperature. Tempering treatments in the range 400 °C to 600 °C, following hardening at the austenitizing temperature used commonly in industrial practice for each alloy, produced significant changes in both hard-ness and wear performance, but negligible changes in fracture toughness. Most importantly, the data showed that selection of the correct temperature for subcritical heat treatment to reduce the retained austenite content for applications involving repeated impact loading is critical if abrasion resistance is not to suffer.

Similar content being viewed by others

References

I.R. Sare and B.K. Arnold:Metall. Mater. Trans. A,1995, vol. 26A, pp 357–70.

ASTM A532-82, American Society for Testing and Materials, Philadelphia, PA, 1982.

J. Dodd and J.L. Parks:Met. Forum, 1980, vol. 3, pp. 3–27.

H.L. Arnson, J.L. Parks, and D.R. Larsen: inIntermountain Minerals Symposium, R.Q. Barr, D.V. Doane, and K.H. Miska, eds., Climax Molybdenum, Ann Arbor, MI, 1982, pp. 25–42.

R. Blickensderfer, J.H. Tylczak, and J. Dodd: inWear of Materials 1983, K.C. Ludema, ed., ASME, New York, NY, 1983, pp. 471–76.

R. Blickensderfer, J.H. Tylczak, and G. Laird: inWear of Materials 1989, K.C. Ludema, ed., ASME, New York, NY, 1989, pp. 175–82.

K.-H. Zum Gahr and D.V. Doane:Metall. Trans. A, 1980, vol. 11A, pp. 613–20.

K.-H. Zum Gahr and G.T. Eldis:Wear, 1980, vol. 64, pp. 175–94.

J. Muscara and M.J. Sinnott:Met. Eng. Q., 1972, vol. 12 (2), pp. 21–32.

M.C. Murphy, R.G. Kumble, J.T. Berry, and J.O. Outwater:Trans. Am. Foundrymen’s Soc, 1973, vol. 81, pp. 158–62.

R.B. Gundlach and J.L. Parks:Wear, 1978, vol. 46, pp. 97–108.

J.D. Watson, P.J. Mutton, and I.R. Sare:Met. Forum, 1980, vol. 3, pp. 74–88.

D.E. Diesburg and F. Borik: inMaterials for the Mining Industry, R.Q. Barr, ed., Climax Molybdenum, Ann Arbor, MI, 1974, pp. 15–38.

I.R. Sare:Met. Tech., 1979, vol. 6, pp. 412–19.

K.-H. Zum Gahr and W.G. Scholz:J. Met., 1980, vol. 32 (10), pp. 38–44.

R.W. Durman:Br. Foundryman, 1981, vol. 74, pp. 45–55.

S.B. Biner:Can. Met. Q., 1985, vol. 4, pp. 155–62.

S.B. Biner:Can. Met. Q., 1985, vol. 24, pp. 163–67.

J.D. Gates, K.D. Lakeland, J.W. Dalton, E.J. Quayle, and M. DeGlas: inMaterials United in the Service of Man, R.D. Davies and D.I. Hatcher, eds., Institute of Metals and Materials Australasia, Perth, Western Australia, 1990, vol. 1, pp. 5-3.1-5-3.10.

F. Maratray and A. Poulalion:Contribution to the Study of the Hardness of Martensitic Structures, the Retention of Austenite,its Control and its Transformation in High Carbon, High Chromium Ferrous Alloys, Climax Molybdenum Publication M-339 E, 1977.

F. Maratray and A. Poulalion:Trans. Am. Foundrymen’s Soc, 1982, vol. 90, pp. 795–804.

R.W.K. Honeycombe:Steels: Microstructure and Properties, Edward Arnold, London, 1981, pp. 152–60.

I.R. Sare and B.K. Arnold:Wear, 1989, vol. 131, pp. 15–38.

K.-H. Zum Gahr:Microstructure and Wear of Materials, Elsevier, Amsterdam, 1987, pp. 181–87.

G.L.F. Powell and G. Laird:J. Mater. Sci., 1992, vol. 27, pp. 29–35.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sare, I.R., Arnold, B.K. The influence of heat treatment on the high-stress abrasion resistance and fracture toughness of alloy white cast irons. Metall Mater Trans A 26, 1785–1793 (1995). https://doi.org/10.1007/BF02670766

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02670766