Abstract

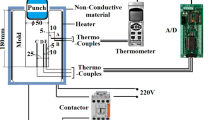

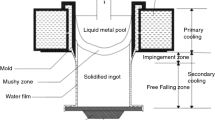

Heat flow at the metal/chill interface of bar-type castings of aluminum base alloys was modeled as a function of thermophysical properties of the chill material and its thickness. Experimental setup for casting square bars of Al-13.2 pct Si eutectic and Al-3 pet Cu-4.5 pct Si long freezing range alloys with chill at one end exposed to ambient conditions was fabricated. Experiments were carried out for different metal/chill combinations with and without coatings. The thermal history at nodal locations in the chill obtained during the experiments was used to estimate the interface heat flux by solving a one-dimensional Fourier heat conduction equation inversely. Using the data on transient heat flux q, the heat flow at the casting/chill interface was modeled in two steps: (1) The peak in the heat flux curve qmax was modeled as a power function of the ratio of the chill thickness d to its thermal diffusivity a, and (2) the factor (q/qmax) X α0.05 was also modeled as a power function of the time after the solidification set in. The model was validated for Cu-10 pct Sn -2 pct Zn alloy chill and Al-13.2 pct Si and Al-3 pct Cu-4.5 pct Si as the casting alloys. The heat flux values estimated using the model were used as one of the boundary conditions for solidification simulation of the test casting. The experimental and simulated temperature distributions inside the casting were found to be in good agreement.

Similar content being viewed by others

References

K. Ho and R.D. Pehlke:Metall. Trans. B, 1985, vol. 16B, pp. 585–94.

L.J.D. Sully:Am. Foundrymen’s Soc. Trans., 1976, vol. 84, pp. 735–44.

J. Isaac, G.P. Reddy, and G.K. Sharma:Proc. 32nd Annual Convention and Technical Meeting, The Institute of Indian Foundrymen, New Delhi, India, Feb. 1984, pp. 15–20.

Y. Nishida, W. Droste, and S. Engler:Metall. Trans. B, 1986, vol. 17B, pp. 833–44.

A.I. Veinik:Thermodynamics for the Foundryman, English Ed., H.K. Barton, ed., Maclaren and Sons, London, 1968, pp. 1–15.

K. Ho and R.D. Pehlke:Am. Foundrymen’s Soc. Trans., 1984, vol. 92, pp. 587–97.

H. Fenech and W.M. Rohsenow:J. Heat Transfer, 1963, vol. 85, pp. 15–22.

Yu.P. Shlykov and Ye.A. Ganin:Int. J. Heat Mass Transfer, 1964, vol. 7, pp. 921–29.

A.M. Clausing and B.T. Chao:J. Heat Transfer, 1985, vol. 87, pp. 243–51.

S.S. Sadhal:J. Heat Transfer, 1981, vol. 103, pp. 32–35.

D.R. Durham and J.T. Berry:Am. Foundrymen’s Soc. Trans., 1974, vol. 84, pp. 101–29.

K. Morgan, R.W. Lewis, and K.N. Seetaramu:Simulation, 1981, vol. 36, pp. 55–63.

E. Gozalan and M. Bamberger:Z. Metallkd., 1987, vol. 78, pp. 677–81.

M. Bamberger, B.Z. Weiss, and M.M. Stupel:Mater. Sci. Technol., 1987, vol. 3, pp. 49–55.

C.V. Kutumba Rao and V. Panchanathan:Am. Foundrymen’s Soc. Trans., 1973, vol. 81, pp. 110–14.

Taylor Lyman:Metals Handbook, 8th ed., ASM, Metals Park, OH, 1970, vol. 5, pp. 274–75.

J.V. Beck:Int. J. Heat Mass Transfer, 1970, vol. 213, pp. 703–16.

J.V. Beck:Int. J. Heat Mass Transfer, 1967, vol. 10, pp. 1615–17.

K. Ho and R.D. Pehlke:Am. Foundrymen’s Soc. Trans., 1983, vol. 91, pp. 689–98.

K. Narayan Prabhu, T.S. Prasanna Kumar, and T. Ramchandran: Poster, Indo-U.S. Workshop on Principles of Solidification and Material Processing, Defence Metallurgical Research Laboratory, Hyderabad, India, Jan. 1988.

W.H. Cubberly:Metals Handbook, 9th ed., ASM, Metals Park, OH, 1979, vol. 2, pp. 155–418.

T.S. Prasanna Kumar, S.D. Pathak, and O. Prabhakar:Am. Foundry men’s Soc. Trans., 1985, vol. 123, pp. 789–800.

T.X. Hou and R.D. Pehlke:Am. Foundrymen’s Soc. Trans., 1985, vol. 93, pp. 493–500.

Author information

Authors and Affiliations

Additional information

Formerly Assistant Professor with Karnataka Regional Engineering College

Rights and permissions

About this article

Cite this article

Kumar, T.S.P., Prabhu, K.N. Heat flux transients at the casting/chill interface during solidification of aluminum base alloys. Metall Trans B 22, 717–727 (1991). https://doi.org/10.1007/BF02679028

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02679028