Abstract

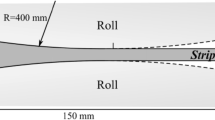

A numerical algorithm for the two-dimensional solidification problem in the twin-roll continuous casting system is presented in this paper. Attention is focused on the elucidation of heat transfer and flow characteristics in both the liquid and the solid phases. The present mathematical model can be applied to general full Navier-Stokes and energy equations, thereby covering the wide range of twin-roll casting conditions. The boundary fixing method (BFM) is adopted to handle the moving boundary, and the resultant transformed governing equations for the solid and liquid regions are solved separately by using a usual explicit-type finite difference method. In this paper, a general numerical methodology is presented, and the quantitative relationships between the important control parameters in continuous casting of twin-roll type (such as the roll speed, the roll gap, the initial temperature of molten materials, the material properties, the solidification profile, and the endpoint of solidification) are clarified in detail. The present numerical results have been compared with experimental results obtained separately to check the validity of the proposed method.

Similar content being viewed by others

References

K. Miyazawa and J. Szekely:Metall. Trans. A, 1981, vol. 12A, p. 1047.

J Szekely: inFree Boundary Problems: Theory and Applica- tions, John Wiley & Sons, New York, NY, 1981, vol. II, p. 283.

I. Ohnaka:J. JSME, 1985, vol. 88, p. 1060.

T. Ohashi:Bull. JIM, 1986, vol. 25, p. 505.

Y.V. Murty and R.P. Adler:J. Mater. Sci., 1982, vol. 7, p. 1945.

N.J. Baek and S.M. Lee:Trans. KSME, vol. 11 (6), 1987, p. 913.

T. Saitoh:J. Heat Transfer, Trans. ASME, 1978, vol. 100, p. 294.

T. Saitoh and H. Kato:Proc. of lnt. Symp. on Cold Regions Heat Transfer, University of Alberta, Edmondton, AB, Canada, 1987, p. 207.

T. Saitoh:Computer-Aided Heat Transfer, Yokendo Publishing Co. Ltd., Tokyo, 1986.

P.G. Kroeger and S. Ostrach:Int. J. Heat Mass Transfer, 1974, vol. 17, p. 1191.

R.S. Carbonara, S.M. Pimputkar, J.J. Rayment, J.L. McCall, and A.H. Clauer:Proc. Vac. Met. Conf, G.K. Bhat and L.W. Lheibier, eds., VMD-AVS, 1984, p. 193.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Saitoh, T., Hojo, H., Yaguchi, H. et al. Two-dimensional model for twin-roll continuous casting. Metall Trans B 20, 381–390 (1989). https://doi.org/10.1007/BF02696990

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02696990